7

Appendix D:

Drying Out Procedure

70

|

nVent.com

Important: Wear full face shield when drying out

MI cable.

Damage to the cable sheath or a damaged or missing

joint or end cap will cause the magnesium oxide

insulation (white powder) to absorb moisture, resulting

in low IR readings. The cable must be “heated out"

to remove the moisture and bring the IR back to an

acceptable level.

If moisture is detected in the cable, use the oxy-

acetylene torch with a large sizzling flame (Appendix

E) and dry out the cable beginning 5 in (13 cm) back

from the end of the cable (heat cold lead first if making

a hot/cold joint). If IR is still low and it was necessary

to remove an additional 10 in (25 cm) to 12 in (30 cm)

of cable, begin heating out the cable 12 in (30 cm) back

from the end of the cable. Alloy 825 sheath cable should

be heated to a dull red color.

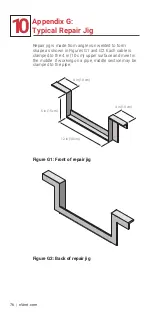

Use a short sweeping motion of the torch and heat

about 2 in (5 cm) of cable at a time, repeating 4 to 5

times. Move the flame towards the joint body or end

cap as shown in Figure D1. Do not sweep the flame in

the opposite direction as this will drive the moisture

into the cable.

2" (5 cm)

Repeat 4 to 5 times

Joint body

Figure D1: Use sweeping motion of torch