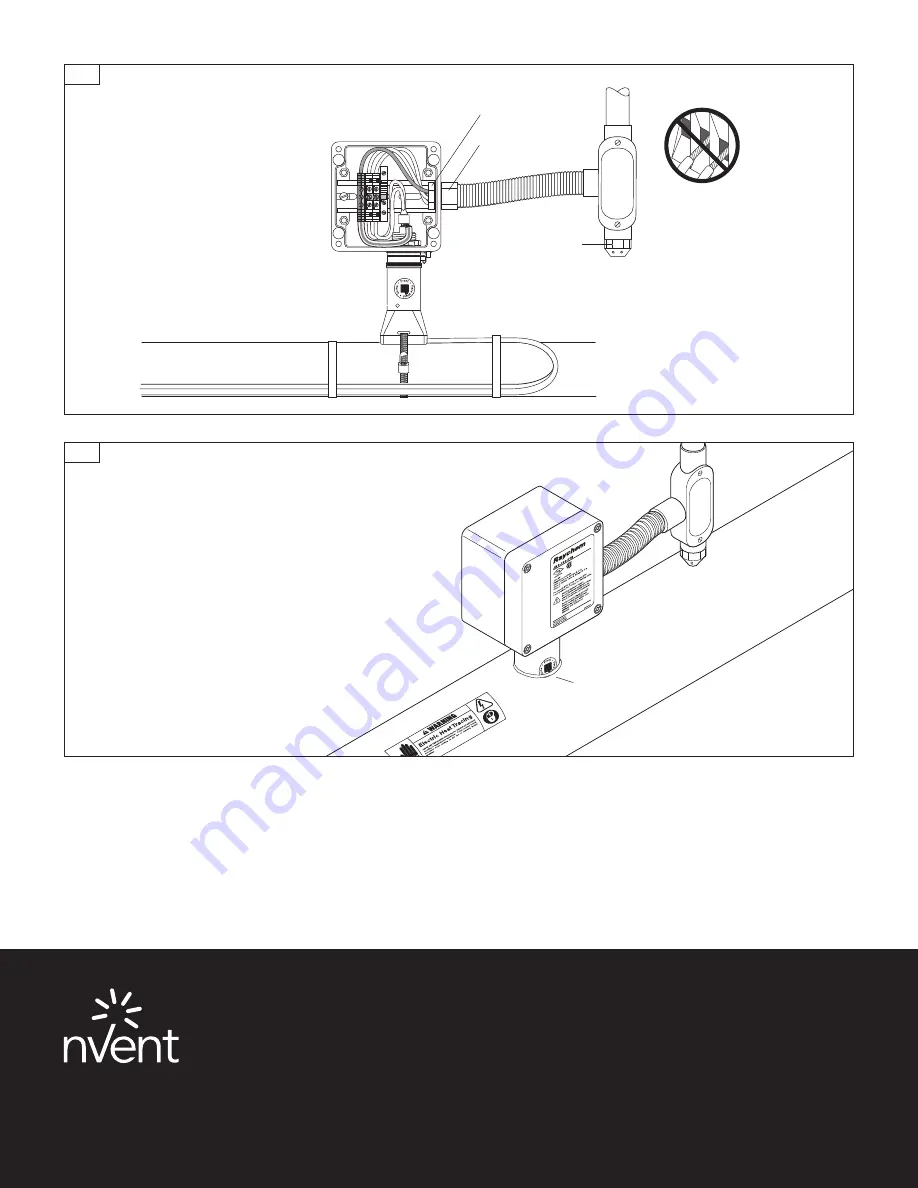

nVent recommends the use

of a conduit drain to prevent

water condensation build-up.

Make sure

conductors are

not exposed.

Conduit

drain

3/4 in locknut

Water tight

conduit seal

Weather seal

17

18

• Install conduit and fittings as shown.

To minimize loosening due to pipe

vibration, use flexible conduit.

• Pull in power and ground wires, strip

off 1/2 in (13 mm) of insulation and

terminate.

• Install lid.

• Apply insulation and cladding.

• Weather-seal the stand entry.

• Leave these instructions with the end user for future

reference.

nVent.com

North America

Tel +1.800.545.6258

Fax +1.800.527.5703

thermal.info@nvent.com

Europe, Middle East, Africa

Tel +32.16.213.511

Fax +32.16.213.604

thermal.info@nvent.com

Asia Pacific

Tel +86.21.2412.1688

Fax +86.21.5426.3167

cn.thermal.info@nvent.com

Latin America

Tel +1.713.868.4800

Fax +1.713.868.2333

thermal.info@nvent.com

©2018 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its affiliates. All other trademarks are the property of their respective owners.

nVent reserves the right to change specifications without notice.

Raychem-IM-H57741-JBS100STB-EN-1805

PN P000000363