Test Procedures

9

nVent.com | 29

• Allow the system to reach the control point. This

may take up to four hours for most circuits. Large,

liquid-filled pipes may take longer.

• Measure the voltage, amperage, and pipe

temperature for each circuit and record the values

in the “Installation and Inspection Record” (refer to

Section 11). This information is needed for future

maintenance and troubleshooting.

• When the system is completely checked out, reset the

thermostat to the proper temperature.

Control and monitoring systems

Refer to the installation instructions supplied with the

product for commissioning tests and records.

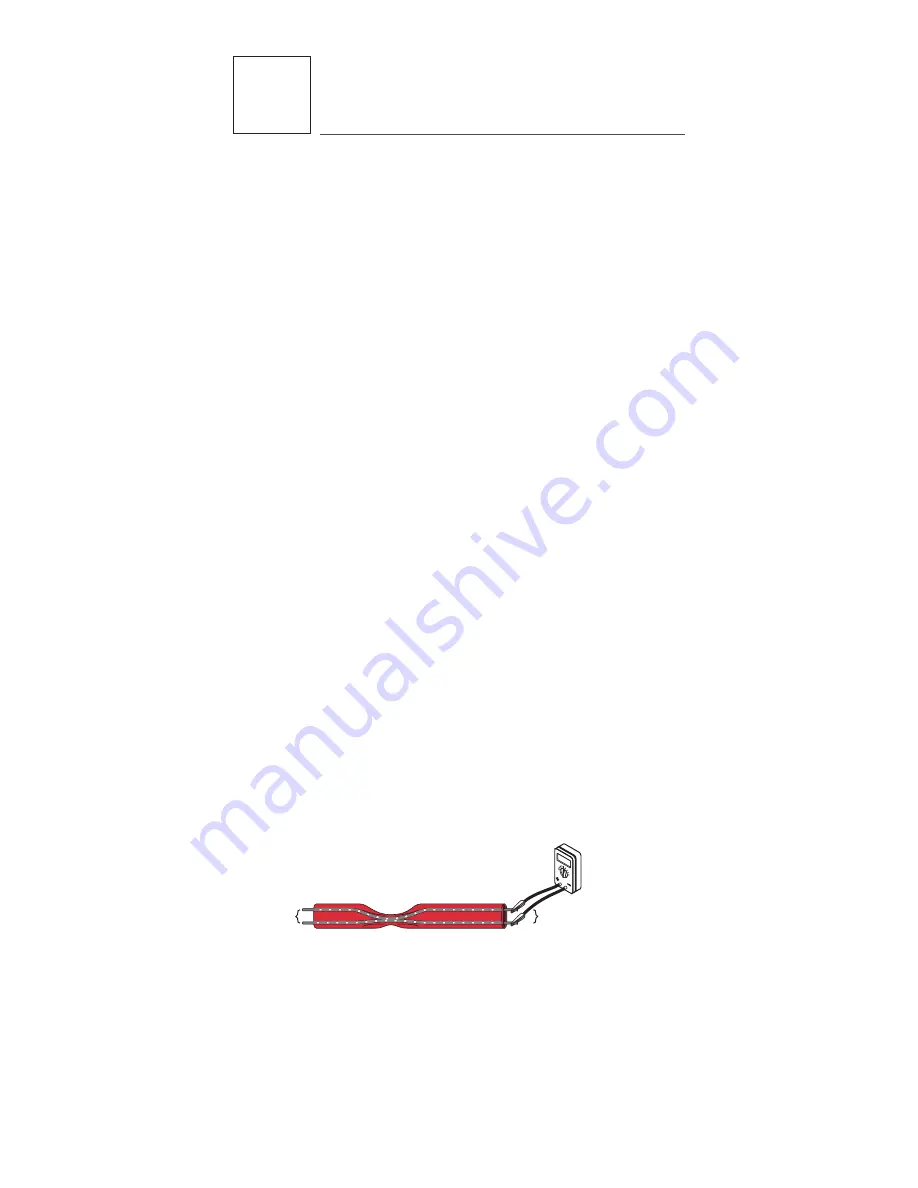

9.4 Fault Location Tests

FAULT LOCATION

There are three methods used for finding a fault within a

section of heating cable: the ratio method, 1/R method,

and the capacitance method. The capacitance method

can also be used to determine total heating cable length.

RATIO TEST METHOD

a.) To locate bus wire short:

The ratio method uses resistance measurements taken at

each end of the heating cable to approximate the location

of a bus wire short. A shorted heating cable could result

in a tripped circuit breaker or a cold section of pipe.

Measure the bus-to-bus conductor resistance

from

the front end (measurement A) and the back end

(measurement B) of the suspected section.

A

B

A

B

A

B

Braid