6 | nVent.com

E

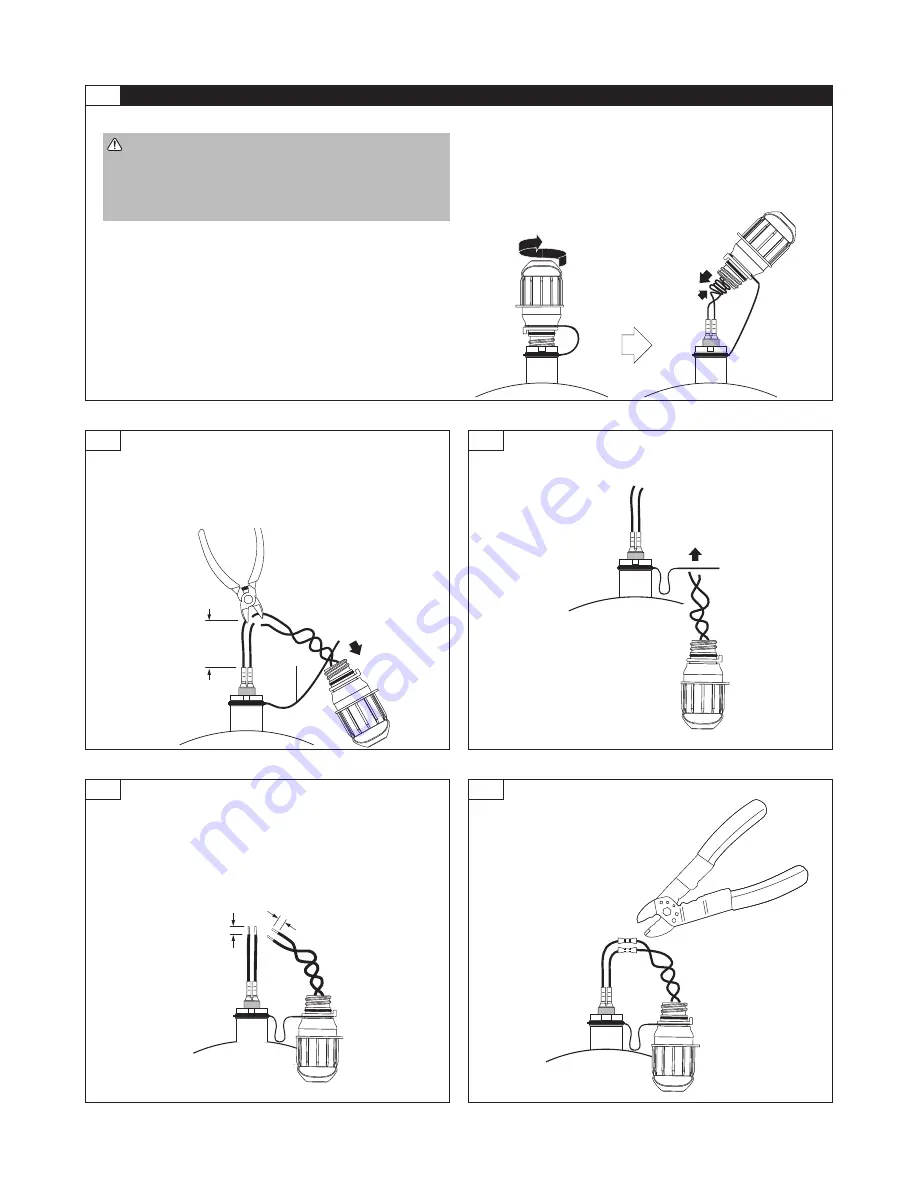

3/8 in

(9 mm)

3/8 in

(9 mm)

D

• Use Panduit CT-100

crimp tool and red

insulated butt splices to

crimp new wires to old

wires.

C

2 in

(50 mm)

Leash

B

• Install new light

into yellow leash.

• Cut existing wires approximately 2 in (50 mm) above top

of crimps or core sealer.

• Remove old light from yellow leash.

• Use 20 AWG wire stripper to remove insulation from each

of the four wire ends.

BEGIN HERE FOR LIGHT REPLACEMENT

On existing light:

• Cut cable tie (if present).

• Unscrew light.

• Pull excess wire from inside light.

Note: The existing light shown in the instructions may look

different from the existing light in your installation.

WARNING: Shock hazard. Electrical conductors will

be exposed. Re-entry should only be performed by

qualified personnel. Turn off power and follow

standard electrical lockout procedures before

opening end seal.

A