12 | nVent.com

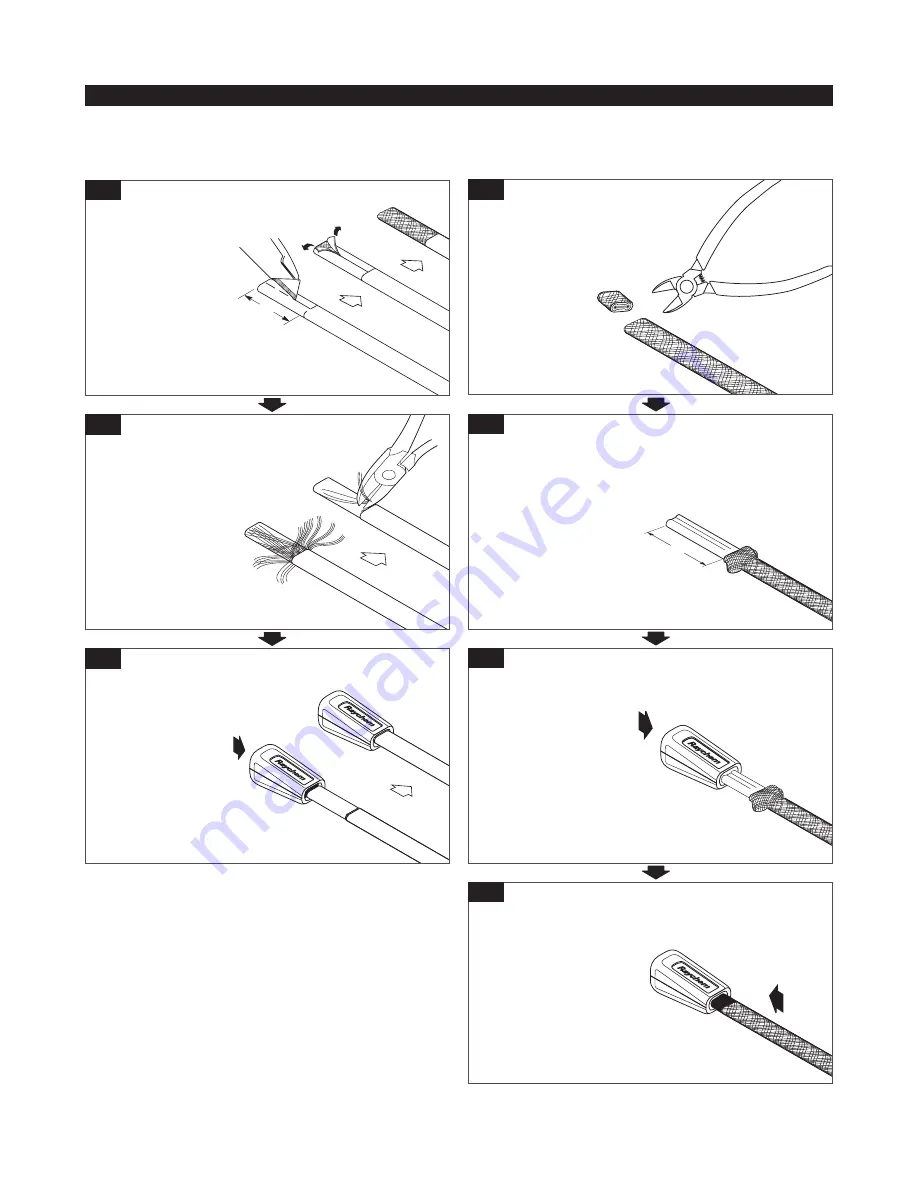

Note: The end seal is designed to be installed only once; it cannot be removed from

the heating cable once installed. Do not use until ready for final installation.

1 in

1A

2A

3A

2 in

1B

2B

3B

4B

• Cleanly cut off the

end of the cable.

• Score down and

around outer jacket

1 inch from the end.

• Remove the

outer jacket.

• Do not cut or damage

inner jacket.

• Unravel and remove

exposed braid.

• Firmly push end

seal onto the cable

(at least 11/2

inches). Some gel

may ooze out.

• Do not twist or try

to remove the end

seal during or after

insertion. Do not

reuse an end seal.

• Firmly push end seal

onto the cable (at least

11/2 inches). Some gel

may ooze out.

• Do not twist or try

to remove the end

seal during or after

insertion. Do not reuse

an end seal.

• Cleanly cut off the end

of the cable.

• Push the braid back 2 inches

from the cable end.

• Slide the braid up

against the end seal

and secure with the

6-inch length of tape

provided.

End Seal for H612

End Seal for H311, H611

H908 END SEAL