DESCRIPTION

The nVent RAYCHEM HAK-C-100 is a connection kit designed for use

in Division 1 hazardous locations with the RAYCHEM industrial heating

cables listed on page 2 of these instructions. The kit contains materials

for sealing one heating cable entry when making a power, splice, tee, or

end termination. A heat-shrinkable core seal is provided specifically for

use with LBTV2-CT heating cables. For all other heating cables, a CS-100

cold-applied core seal is provided.

Refer to the Heat-Tracing Systems Design and Installation Guide for

Hazardous Div. 1 Locations (H56075) for assistance in the design of each

heat-trace system. For technical support call nVent at (800) 545-6258.

This component is an electrical device that must

be installed correctly to ensure proper operation

and to prevent shock or fire. Read these important

warnings and carefully follow all of the installation

instructions.

• To minimize the danger of fire from sustained

electrical arcing if the heating cable is

damaged or improperly installed, and to

comply with nVent requirements, agency

certifications, and national electrical codes,

ground-fault equipment protection must

be used. Arcing may not be stopped by

conventional circuit breakers.

• Component approvals and performance are

based on the use of nVent-specified parts only.

Do not substitute parts or use vinyl electrical

tape.

• Keep components and heating cable ends dry

before and during installation.

• The black heating cable core and fibers are

conductive and can short. They must be

properly insulated and kept dry.

• Damaged bus wires can overheat or short. Do

not break bus wire strands when scoring the

jacket or core.

• Use only fire-resistant insulation materials,

such as fiberglass wrap or flame-retardant

foam.

• Heat-damaged components can short. Use

a heat gun or a torch with a soft, yellow,

low-heat flame. Keep the flame moving to

avoid overheating, blistering, or charring the

heat-shrinkable tubes. Avoid heating other

components. Replace any damaged parts.

Health Hazard: Prolonged or repeated contact with

the sealant in the core sealer may cause eye or

skin irritation. Wash hands thoroughly. Overheating

or burning the sealant will produce fumes that may

cause polymer fume fever. Avoid contamination of

cigarettes or tobacco. Consult MSDS VEN 0058 for

further information.

Overheating heat-shrinkable tubes will produce

fumes that may cause irritation. Use adequate

ventilation and avoid charring

or burning. Consult MSDS RAY3122 for further

information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258.

CAUTION:

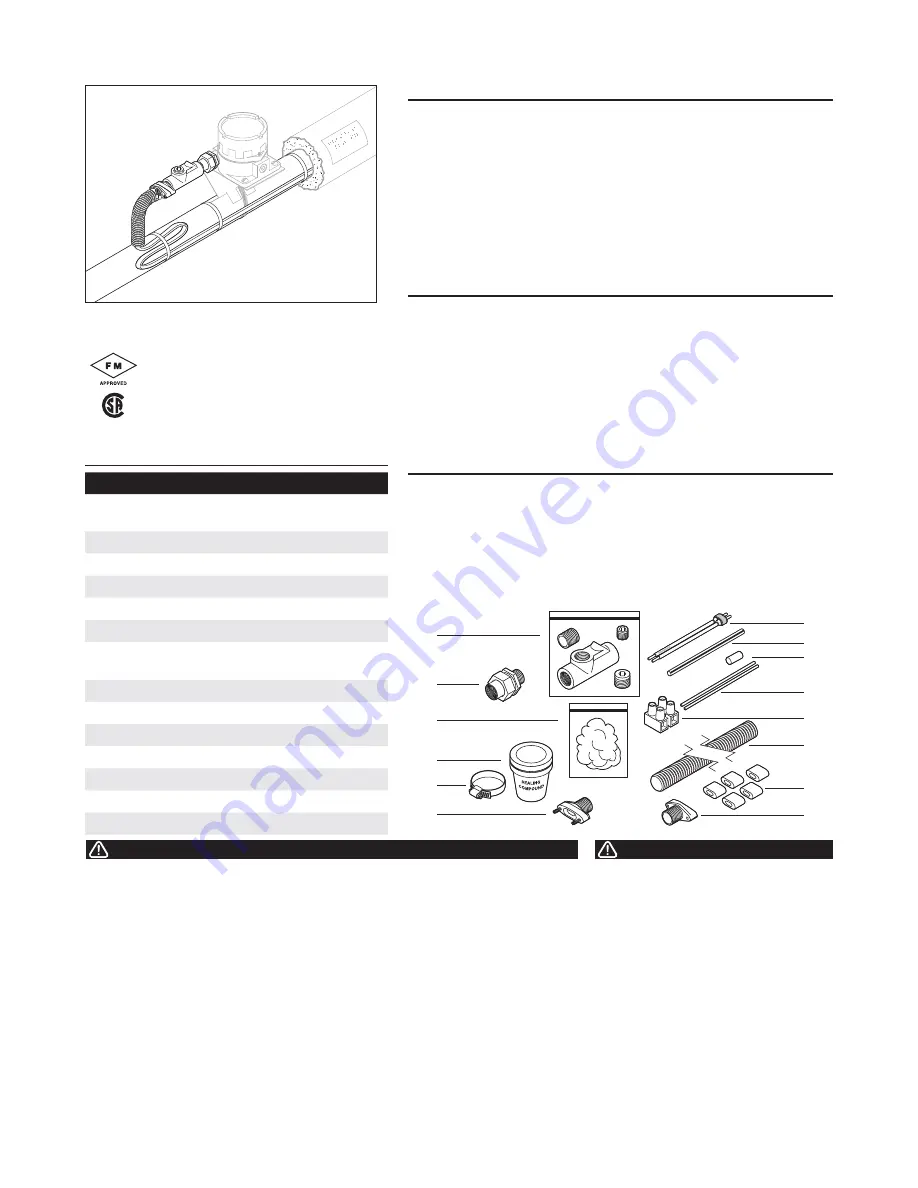

Item

Qty

Description

A

1

HAK sub-assembly: sealing fitting,

nipple, and plugs

B

1

Union

C

1

Packing fiber

D

1

Sealing compound

E

1

Tubing clamp

F

1

Compression gland with screws

G

1

Compression gland with threaded

inserts

H

5

Grommets (B, C, E, K, R)

I

1

Flex tube

J

1

Terminal block (max: 6 AWG wire)

K

2

Black heat-shrinkable tubes

L

1

Clear yellow heat-shrinkable tube

M

1

Green/yellow tube

N

1

CS-100 core sealer

A

B

C

D

E

F

G

H

I

J

K

L

M

N

APPROVALS

(1)

Except VPL.

(1)

Hazardous Locations

Class I, Div. 1, Groups B, C, D

Class II, Div. 1, Groups E, F, G

Class III

WARNING:

TOOLS REQUIRED

• 1/2 in drive ratchet

• Marking pen

• Diagonal cutters

• Utility knife

• Needle nose pliers

• 5/16 in hex key

• 3/16 in slotted screwdriver

• Ruler

• 1/4 in hex key

• Pipe wrenches (2 required)

• 1/16 in hex key

• Wire strippers (for VPL only)

• 2500 Vdc Insulation Resistance

Tester

• Heat gun or minitorch (required if

heat-shrinkable core seal is used)

ADDITIONAL MATERIALS REQUIRED

• Junction box: RAYCHEM HAK-JB3-100 or agency-approved Division

1 hazardous location 3/4 in NPT junction box. Junction boxes other

than the HAK-JB3-100 may not be compatible with the RAYCHEM

universal mounting bracket.

• Small volume of water

• Universal mounting bracket (UMB)—one per junction box

• Pipe strap—one per mounting bracket

KIT CONTENTS

nVent.com

|

2