8

Hold model securely when starting

9

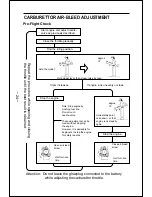

Setting the throttle

10

Heat glowplug

Starter

Assistant should hold

the model so that it

cannot move forward

when the engine starts.

Be careful not

to be hit by propeller!

Fully opened

position

Fully closed

position

Set at this Position.

Starting battery

Connect battery leads as shown

(polarity is immaterial.)

11

Apply electric starter

Assistant

Glowplug battery.

Place as far to the

rear as possible.

17

Summary of Contents for FS-40S

Page 39: ...MEMO 38...