6

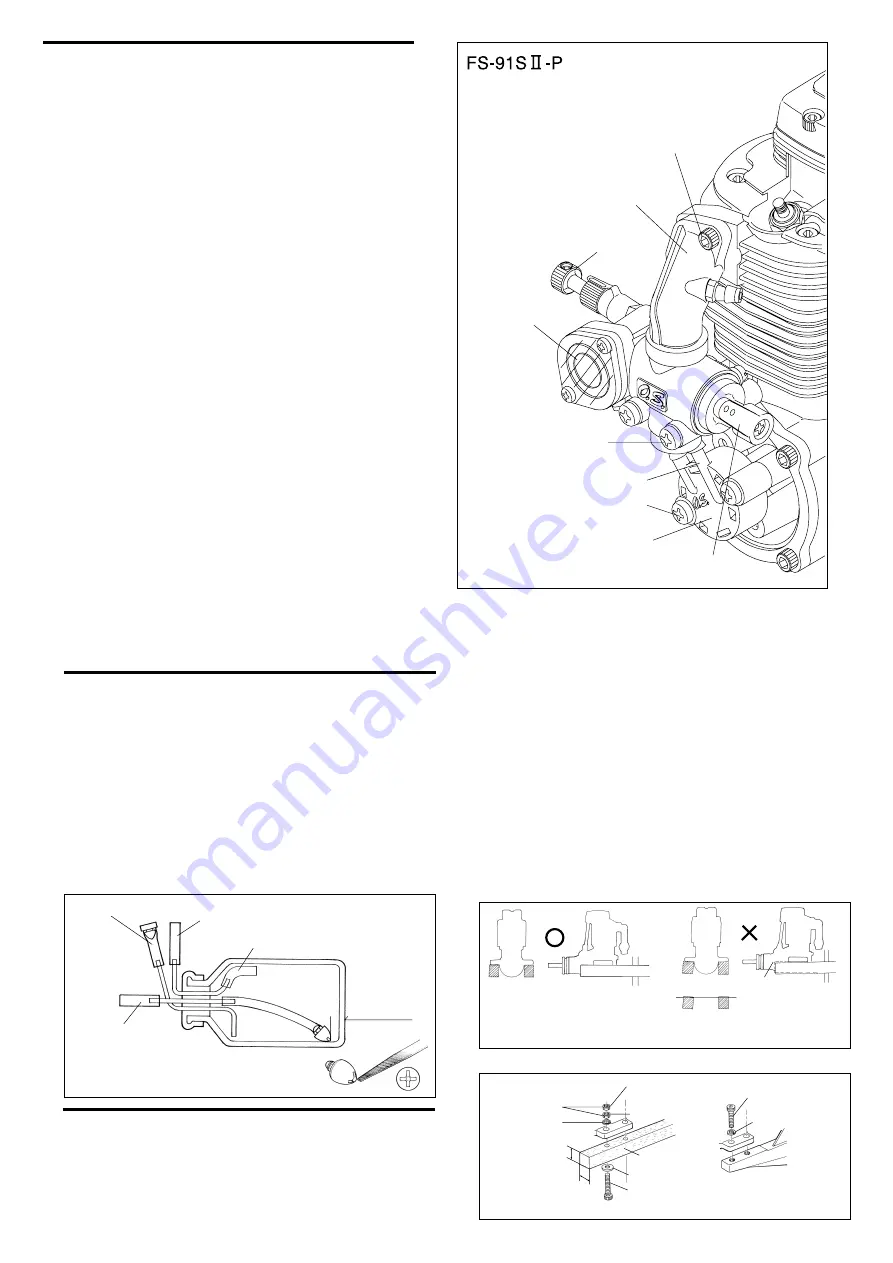

As supplied, the FS-70S

Ⅱ,

FS-91S

Ⅱ

and FS-91S

Ⅱ

-P have their

throttle lever on the right hand side and needle-valve control on

the left. However, where more convenient for certain installations,

these positions may be reversed after rotating the carburettor

through 180˚ horizontally.

Proceed as follows:

1.

2.

3.

4.

5.

RELOCATION OF CARBURETTOR CONTROLS

Remove the intake pipe mounting screws from the cylinder head

(taking care not to lose the flange gasket [91S

Ⅱ

/91S

Ⅱ-

P] ) and

the carburettor mounting screws from the crankcase cover plate

bracket.

Detach short tubing connecting carburettor to pump unit (FS-

91S

Ⅱ

-P) and gently rotate the carburettor through 180

°

without

separating it from the intake pipe or removing the enclosed O-

ring seal.

Re-install the complete sub-assembly of intake pipe and

carburettor, making sure that adjoining surfaces are clean.

Tighten screws evenly and firmly but not excessively.

Remove pump mounting screws from the crankcase cover

plate lugs, carefully rotate the pump clockwise one-quarter turn

and attach it to the second pair of lugs provided, taking care that

the central tubing connecting the crank chamber to the pump

diaphragm chamber is not twisted.

Finally, make sure that all external tubing connections are

secure and do not leak.

Intake Pipe

Mounting Screw

Intake Pipe

Throttle Lever

Carburettor

Mounting Screw

Needle Valve

FueI Inlet

PD-07 Pump

Pump Mounting Screw

Pressure Regulator

7

⇔

10〜15mm

Because these are powerful, large-displacement, single-cylinder

four-stroke-cycle engines, it is essential to use very substantial

engine mounting. Conventional wooden mounting beams should

be of rigid hardwood and of at least 15mm or 5/8-in square

section.

INSTALLATION

FUEL TANK

A fuel tank of approximately 300cc capacity is suggested. This

allows up to 12-13 minutes flying time, dependent upon the type of

fuel used, the size of the propeller and on the proportion of full-

throttle to part-throttle operation through the flight. Make sure that

the tank is well rinsed out with methanol or glow fuel before

installation and that the pickup weight is well clear of the bottom of

the tank when held vertically (see sketch). To prevent the pickup

from adhering to the tank wall under suction and restricting fuel

flow, slots may be filed in the end of the weight as shown.

Alternatively, a Non-Bubble type weight (Code No. 71531000)

may be used.

Make sure that the mounting beams are parallel and that their top

surfaces are in the same plane.

How to fasten the mounting screws.

Hardwood mounting beams

O.S. radial motor mount

(cast aluminum)

For filling or emptying tank

To fuel inlet

Air vent

Use thick-walled sillcone tubing

Tighten second nut firmly

down onto first nut.

Tighten this nut first.

Steel washer

3.5mm steel nuts

4mm steel screw

Spring washer or

lock washer

15mm min.

15mm min.

Hardwood such as

cherry or maple.

Spring washer

3.5mm steel Allen screw

Make sure that these mounting beams are accurately aligned and

firmly integrated with the airframe, reinforcing the adjacent

structure to absorb vibration. Use 3.5mm or larger steel screws,

preferably Allen type hexagon socket head cap screws, with

washers and locknuts, for bolting the engine to the bearers.

As an alternative to wooden beam mounting, a special O.S. cast

aluminium radial motor mount, complete with 3.5mm mounting

screws, is available as an optional extra part, where front bulkhead

(firewall) type mounting is called for. Engine installation should, in

any case, be made in such a way that basic maintenance can be

conveniently carried out.

Front view

CORRECT

Side view

Top surfaces are in the same plane.

Re-align the surfaces

as necessary

INCORRECT

Top surfaces are not

in the same plane.

Opposite beam

Top surfaces are not

in the same plane.

Engine does not

rest firmly.