SUBSEQUENT READJUSTMENTS

Once the engine has been run-in and the carburetor

controls properly set up, it should be unnecessary to

alter the mixture settings, except to make minor

adjustments to the Needle Valve occasionally, to take

account of variations in climatic condisitions.

The use of a different fuel, however, particularly one

containing more, or less, nitromethane and / or a

different type or proportion of lubricating oil, is likely to

call for some readjustment of the Needle-Valve.

Remember that, as a safety measure, it is advisable

to increase the Needle Valve opening by an extra

half-turn counter-clockwise, prior to establishing a

new setting. The same applies if the silencer type is

changed. A different silencer may alter the exhaust

pressure applied to the fuel feed and call for a revised

Needle-Valve setting.

The use of a different glowplug, or changes to the

mainrotor and its pitch angles may also require

compensating carburettor readjustments.

CARBURETOR CLEANLINESS

The correct functioning of the carburetor depends on

its small fuel orifices remaining clear. The minute

particles of foreign matter that are present in any fuel

can easily partially obstruct these orifices and upset

mixture strength so that engine performance

becomes erratic and unreliable. It is recommended

that fuel is passed through a filter when the tank is

filled and that a good in-line filter is installed between

the fuel tank and carburettor and, furthermore, that

this filter is frequently cleaned to remove dirt and lint

that accumulates on the filter screen. Finally,

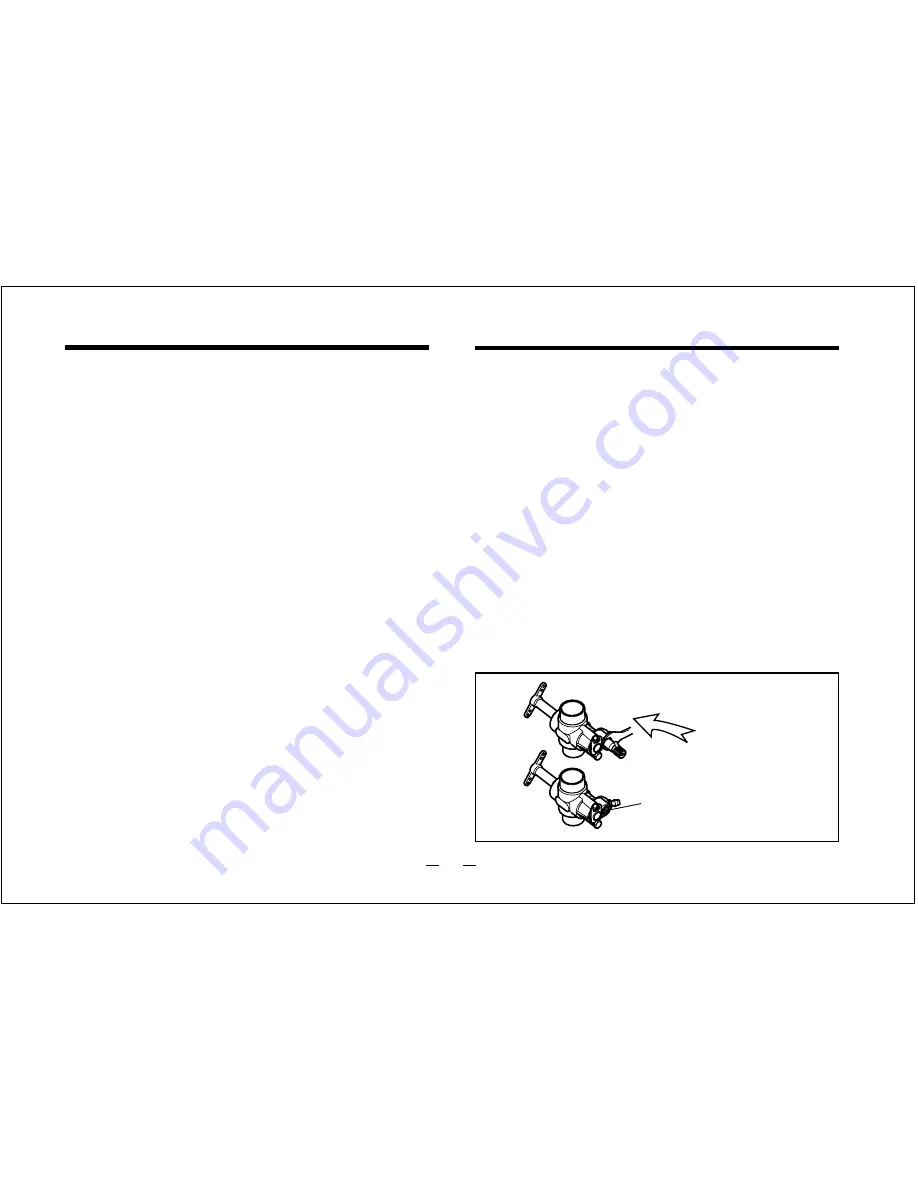

occasionally remove the needle-valve holder from the

carburetor as shown in Sketch and extract any

remaining foreign matter that may have lodged in the

location shown in Sketch.

Remove this with

an 8mm spanner

Dirt and fbrous matter

mostly accumulate here

18