16

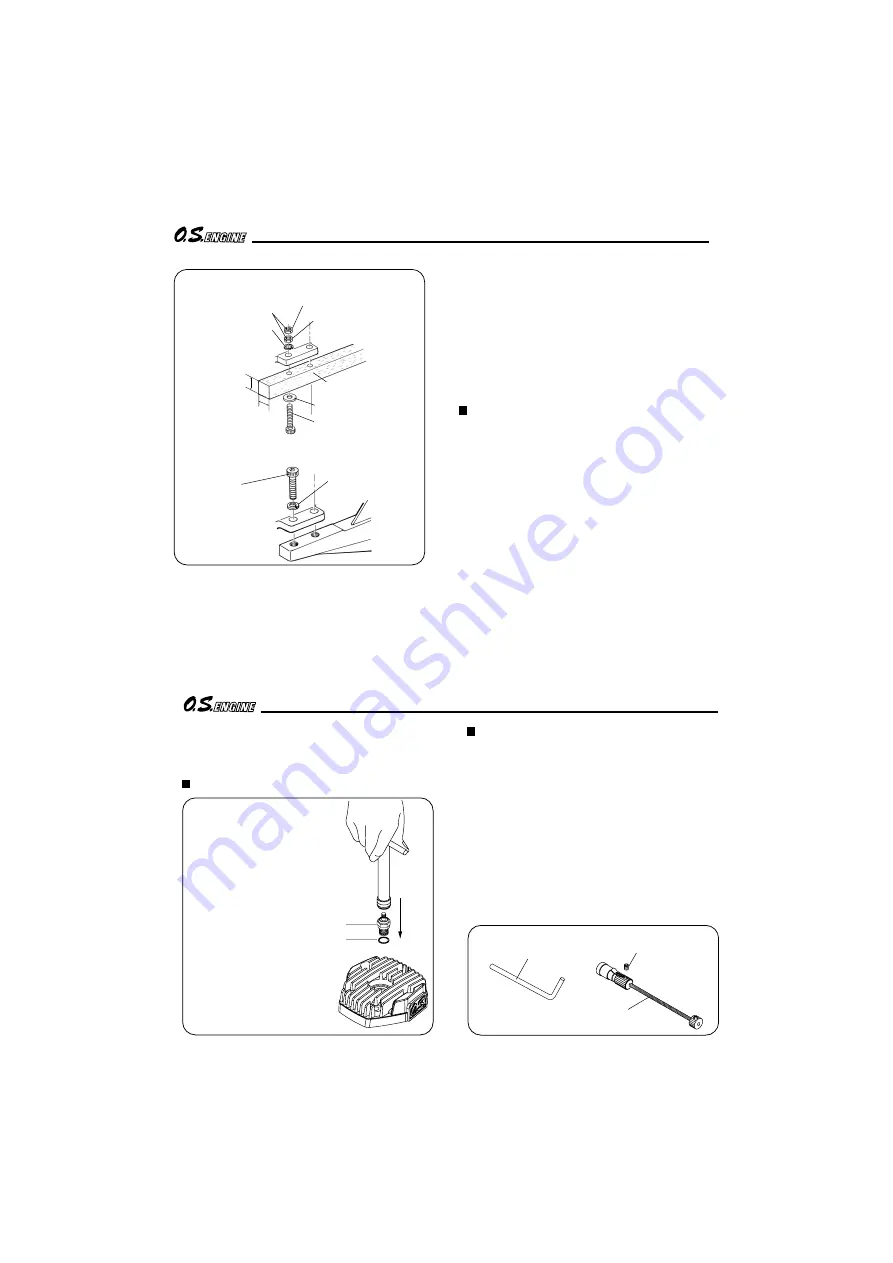

How to fasten the mounting screws.

Hardwood mounting beams

Radial motor mount (cast aluminum)

Tighten second nut

firmlydown onto first nut.

Tighten this nut first.

Steel washer

3mm steel nuts

3mm steel screw

Spring washer or

lock washer

15mm min.

15mm min.

Hardwood such as

cherry or maple.

Spring washer

3.5mm

steel Allen screw

●

Make sure that these mounting beams are accurately

aligned and firmly integrated with the airframe,

reinforcing the adjacent structure to absorb vibration.

Use 4mm or larger steel screws, preferably Allen

type hexagon socket head cap screws, with washers

and locknuts, for bolting the engine to the bearers.

O.S. Radial Motor Mount

A special O.S. radial motor mount (Code No.71905200)

is available, as an optional extra, for use where firewall

type mounting is required.

THROTTLE LINKAGE

Before connecting the throttle to its servo, make sure that

the throttle arm and linkage safely clear any adjacent part

of the airframe structure, etc., as the throttle is opened

and closed. Connect the linkage so that the throttle is

fully closed when the transmitter throttle stick and its trim

lever are at their lowest settings and fully open when the

throttle stick is in its fully-open position. Carefully align

the appropriate holes in the throttle arm and servo horn

so that they move symmetrically and smoothly through

their full travel.

17

INSTALLING THE GLOWPLUG

Install washer on glowplug

and insert carefully into

cylinder-head, making sure

that it is not cross-threaded

before tightening firmly.

Glow plug

Washer

NEEDLE-VALVE EXTENSION

The needle-valve supplied with this engine is

designed to incorporate an extension so that,

when the engine is enclosed within the

fuselage, the needle-valve may be adjusted

from the outside. For this purpose a Needle

Valve Extension Cable Set is supplied with the

engine. If a longer extension is reguired, cut a

commercially available rod to the required

length, bend one end to an L shape, insert it

into needle's center hole and secure it by

tightening the set-screw in the needle-valve

knob with 1.5mm Allen key.

Needle Valve Extension Cable Set

1.5mm Allen key.

Set Screw

INSTALLATION OF THE

STANDARD ACCESSORIES