Zeta 5W Series Manual - V2.8

© Oak Stoves 2018

10

Cleaning & Maintenance

Our stoves are finished with high temperature resistant paint which can withstand the

temperatures expected in normal use. You may clean the stove with a damp lint-free cloth,

but ensure the stove is completely cold throughout before doing so.

To clean the glass on the door, again use a damp lint-free cloth to clean and ensuring that

you wipe with a dry cloth afterwards. Do not use any chemicals to clean the glass, this will

cause permanent damage to the glass. You may get deposits on the glass after the fire has

run, most of these will burn off if you run the fire again at a fast rate for a few minutes. Do not

use abrasive cloths on the glass or paintwork as these can cause scratching and permanent

damage to the stove.

Ash Clearance

With wood or peat fires you should allow some

build up of ash at the base of the firebox, however

it is necessary to remove some ash once the

build up gets too much. This will only be needed

when the build up starts to restrict the airflow by

blocking the front grill. Burning smokeless fuels

will require the ashpan to be emptied regularly, it

is very important to do this as this ash must not be

allowed to overflow over the grate.

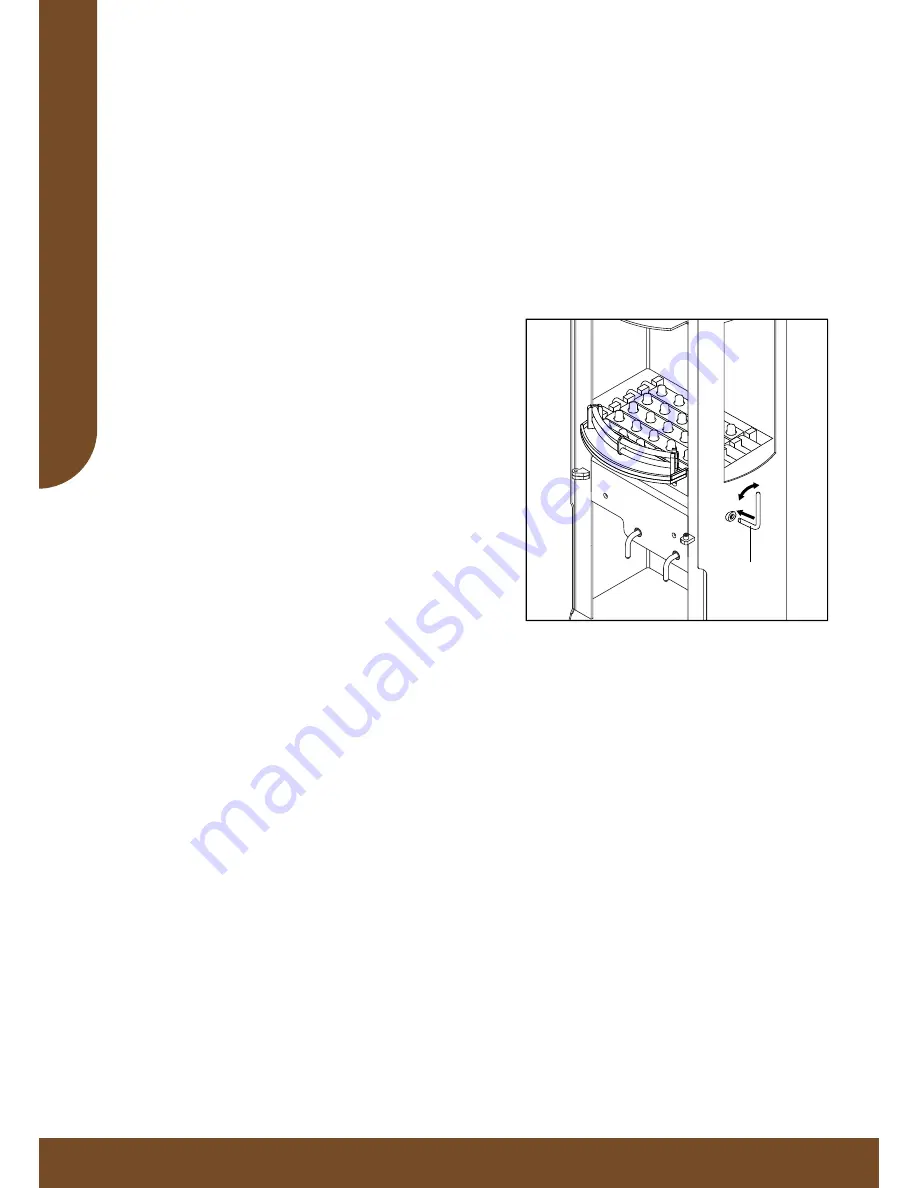

This model has a Remote Riddle Plate Handle

located under the left side of the door, pulling

this bar will rotate the grills allowing excess ash

to drop through to the ashpan below the firebox

(see Fig. 4)

.

Be sure not to completely empty

the base of ash.

It is very important that all ash is cool before attempting to remove it from either the base or

the ashpan. We advise emptying the cold ash into a bin liner and sealing it before disposing.

Throat, Baffle Plate & Flueway Cleaning

It is very important that the throat, baffle plates and the flueway are kept clean and obstruction

free, failure to do so could result in dangerous emissions not escaping correctly. These fumes

can pose a serious health risk to occupants therefore it is necessary to clean both the throat

and baffle plates and the flueways at least weekly, or more frequently if needed.

To clean the throat and baffle plates, first remove the side bricks to enable you to easily

remove the throat plate. To access the flueway, remove the two saddle clips to release the

upper fibre board that covers the flueway. Any build up of soot should then be swept off the

plate down onto the fire. Refit parts in reverse order when cleaning is finished, for more detail

please refer to page 19.

Fig. 4

Oper

a

ting Ins

tructions

Rotating

Riddle

Handle