Electrical Troubleshooting Guide

Please use the following instructions to operate the barrier manually, the following

is assuming you have powered down the unit.

As stated at the beginning of this manual we recommend a bi-annual service, but at a bare minimum, it is imperative

that you get a service done once every 12 months. This is not a sales tactic in disguise, there is a very serious

health and safety issue/risk associated with not complying to this. Also in order for your barrier to keep complying

with the appropriate legislation.

Before carrying out any maintenance to the installation, disconnect the mains power supply.

Make sure you have disconnected/Isolated the power before attempting any work.

A Maintenance Contract should be sought from a specialist company after a maximum of 5000 manoeuvres or 1year from

the install date.

Occasionally clean the photocell optical components and make sure they are free from dirt, water, rain, soil etc.. ? Batteries

in photo cells may need to be changed every 6 months or sooner dependant on use. Barrier will not work properly without

photo cell function.

Have a qualified technician (installer) check the correct setting of the electric clutch.

If the power supply cable is damaged, it must be replaced by the manufacturer or its technical assistance service, or else by

a suitably qualified person, in order to prevent any risk.

When any operational malfunction is found, and not resolved, disconnect the mains power supply and request the

assistance of a qualified technician (installer). When automation is out of order, activate the manual release to allow the

opening and closing operations to be carried out manually.

Gearbox drive unit is “sealed” for life and requires no further lubrication.

!

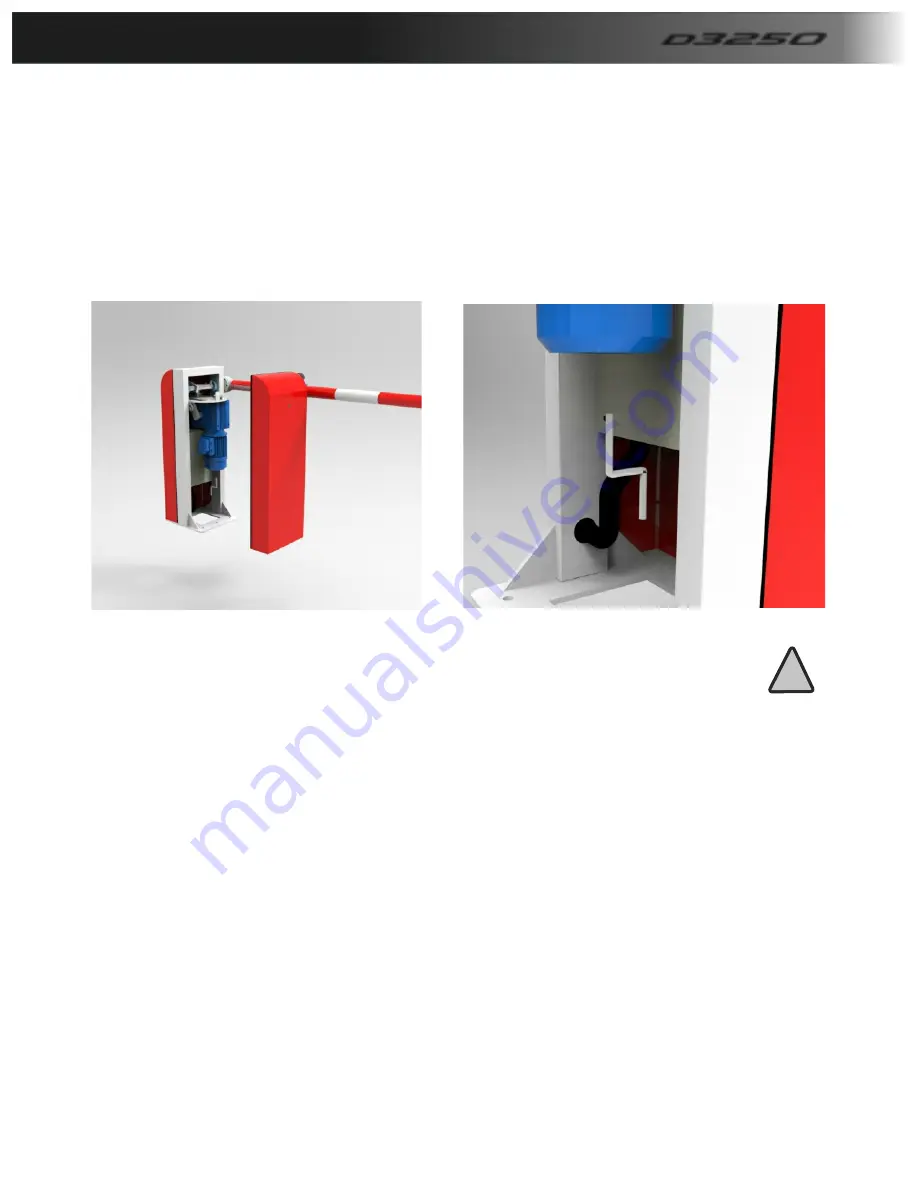

To Manually release the barrier please remove the cover using key supplied, then take the

release Handle ( which will be handed over with the keys ) and insert into the motor and rotate.

Direction depends on Barrier handing. Once the barrier is wound to the desired position replace

the release key and replace the cover and re-lock.

Note the cover has a safety switch on it that will not allow the barrier to operate if the cover is

Not fully closed.

D

3250

Manual Release.