D

3250

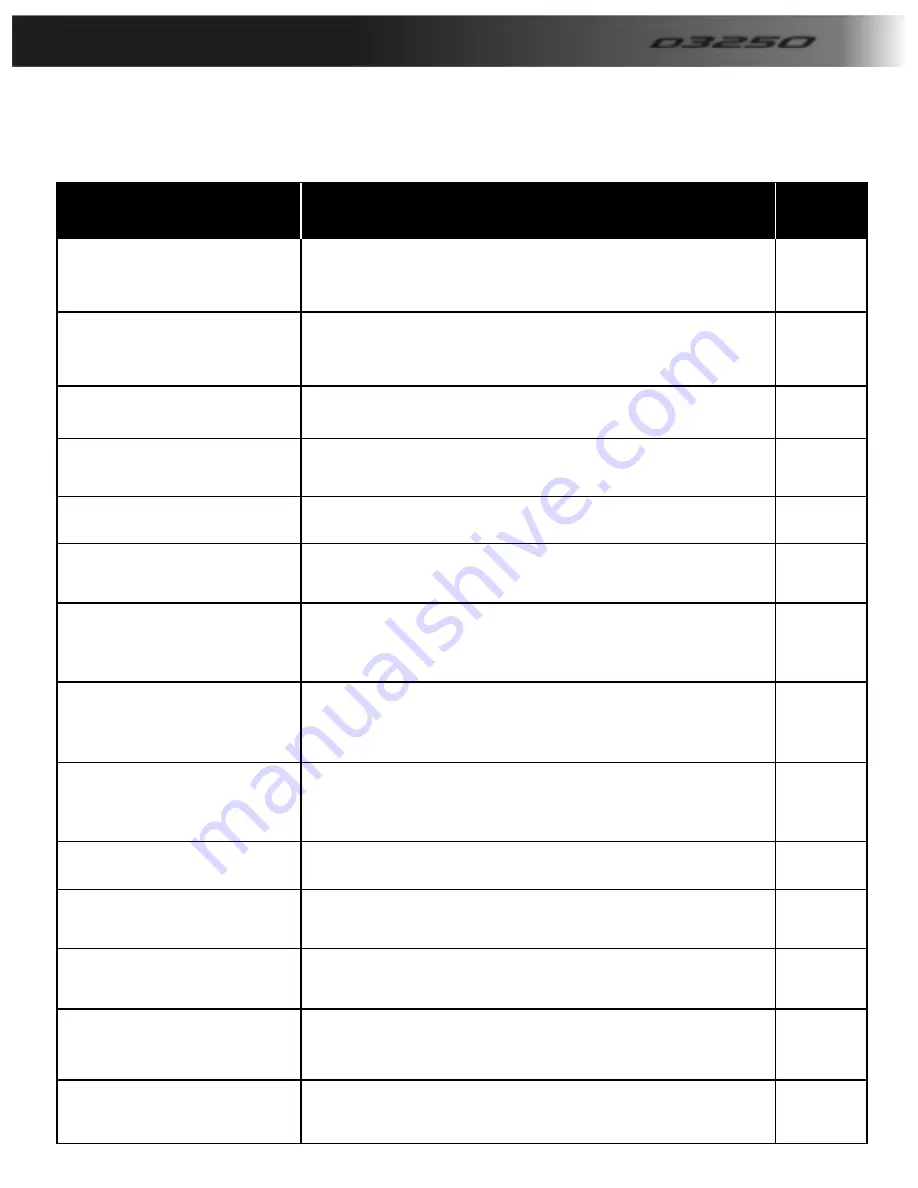

Barrier parameters

Barrier parameters

Description

Default

No Pass Timer

This turns on a timer that times out and lowers

The barrier if no vehicle passes through the loops

Or photocells. This timer is located in Timers.

OFF

Safety Reverse

This allows the barrier to raise back up if the loops

Or photocells are activated whilst the barrier is

Lowering.

OFF

Loop/Photocell Close

This closes the barrier once the loop or photocells

Have been activated.

OFF

Boom Lights

This turns the output on for Boom lights to operate,

The lights will turn off in the up position.

OFF

Flashing Boom Lights

This enables the Boom lights to flash

OFF

Slow down

This enables the barrier to slow down after a set

Time, The timer for this is located in timers.

ON

Inverter Outputs

The Plc runs the inverter via a network cable, this

Option turns on the outputs to run an inverter hard

Wired.

OFF

Raise Timeclock

This turns ON the raise timeclock which will hold the

Barrier up at set times of the day. See timeclock

Setup on page 18.

OFF

Auto Timeclock

This turns on the Timeclock that disables the auto

Loop from operating at set times of the day. See

Timeclock set up on page 18.

OFF

N/O Safety

This turns the safety input into normally open

OFF

Master/slave

This turns on the master/slave outputs to operate

A slave barrier from. Q6 = Raise Q7 = Lower

OFF

Traffic light

This turns on the traffic light output

OFF

Kerb Interlock

This turns on the kerb interlock program, see your

Supplier for connection/operation details.

OFF

2 Step logic

The 2 step logic allows the raise input to lower

The barrier once raised.

OFF

Below is a table of all the parameters available to set in the barriers PLC, Please note there may be

Bespoke programs developed for certain companies where the parameters may be differ from below.