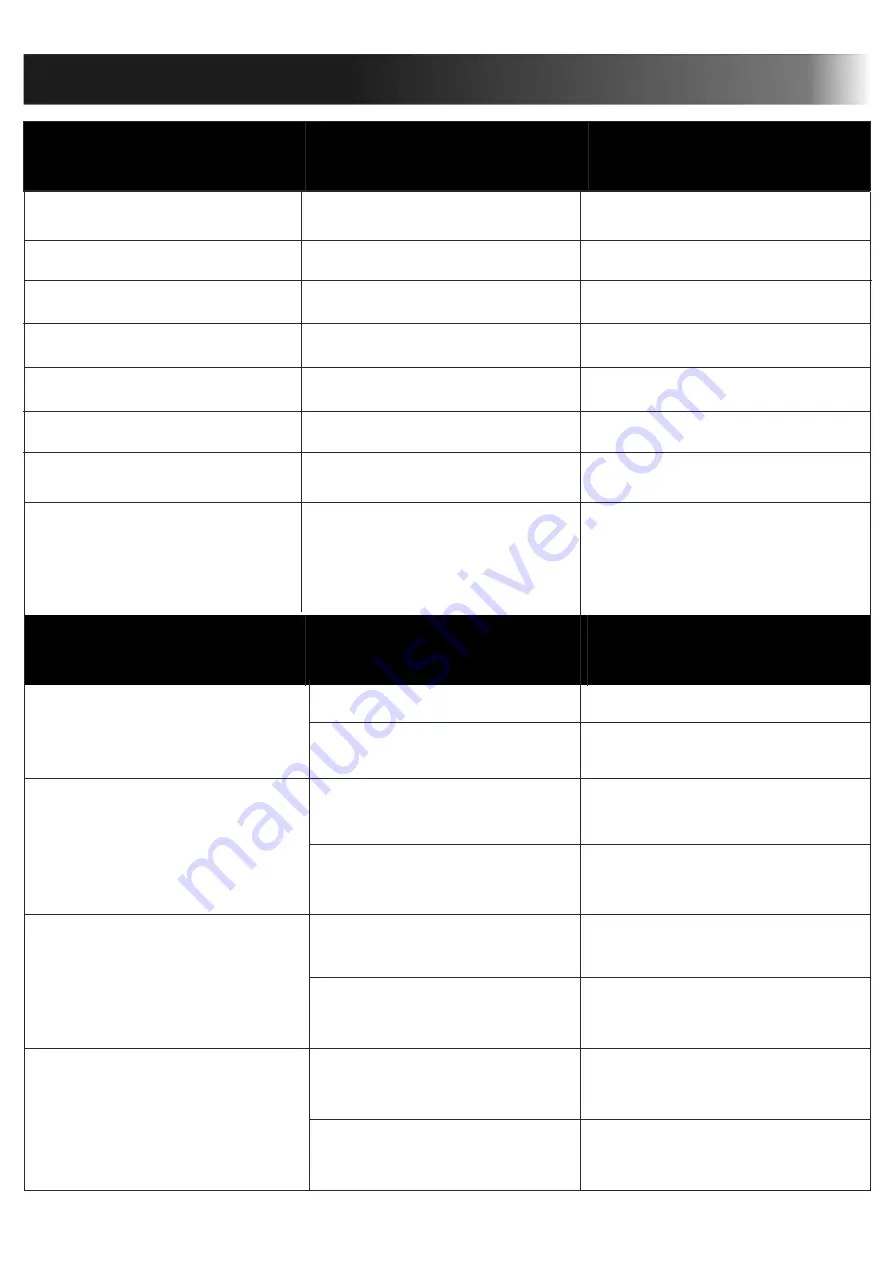

ELECTRICAL ERRORS

CAUSE

CORRECTION

MECHANICAL ERRORS

CAUSE

CORRECTION

Turnstile is free wheeling

Paddles are not latched in

check manual release keyswitches

Rotor is not spining

Check bearings top/bottom

Oil or grease bearings

Blank screen on PLC but power to other devices

in the control panel

On-board fuse blown

Replace fuse and reset barrier

PLC has developed an electrical fault or had a

power spike

Change PLC

Troubleshooting Guide

Rotor has a lot of play when locked

Check paddle bolts

Tighten both paddle bolts

Turnstile making grinding noise

Top Cog/Spring assist requires lubrication

Lubricate both items

Turnstile Rotor is tight

Turnstile is out of square/level

check turnstile/frame is all square/level

Turnstile Rotor is tight

Bottom bearing is ceased

Replace bottom bearing

Turnstile Free wheels

If fail safe turnstile then solenoids may

have no power

Check solenoid relay and replace if faulty

If fail secure turnstile then solenoids may

Have permanent power

Check solenoid relay and replace if faulty

Turnstile lets more then one

Person pass through

Limit switches are not working

Adjust position of limit or replace if faulty

Access control signal set too long

Turn access signal down to 1 second

No 24DC to Plc or other devices

24V PSU faulty

Change PSU

Blown fuse

Replace fuse

D4150