Operating the Turnstile

PF4000FH

7

1.Before attempting the steps outlined below please obey common sense and be aware that the turnstile

will inhibit movement until commissioned so provide a diversion and inform site inc pedestrians.

2.

3.

4.

Follow the manual release guide in this manual and make sure the turnstile moves un-hindered by

inserting the key and checking rotation in both directions.

If the above step is ok then proceed to close the Turnstile using the manual method and then power on

using the isolator switch as shown (if fitted).

Now the cabinet door must be closed for the Turnstile to work automatically.

1.

2.

3.

4.

There are many options to operate the Turnstile as it is dependant upon which type of access control you

have connected. However there is a standard way to operate the Turnstile by using the key switch and the

PLC . Instructions are assisted by pictures below.

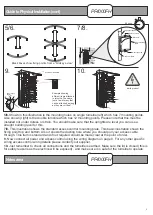

1. Picture shown below is the key switch which is located on the outside of the Turnstile cabinet (it will always be on

the opposite side to the Turnstile arm, also picture shows the key switch keys.

2. To move the Turnstile arm using the PLC first make sure the screen says “RUN LD” if it does not follow the

troubleshooting guide on page 11 when the screen says “RUN LD” follow below.

3.

4.

To make the Turnstile move upwards or to “open” press the up arrow.

To make the Turnstile move down or to “close” press the down arrow.

Please note that the above 2 manoeuvres will not work if there is something in the way of photocells or on the loops.

1.

2.

3.

4.

Key switch

keys

This key switch is mounted on

the side of the Turnstile

Key switch

An isolator is fitted

to activate push

forward to power

on the turnstile.

First Operation Manoeuvres

ROUTE

CLOSED

Auto

Open

IDEC

IDEC

Menu/Ok

SR2 B121BD

1

2

Q1

1

2

Q2

1

2

Q3

1

2

Q4

+

-

I1

I2 I3 I4 IB

ID

IC

IE

24VDC

24VDC

24VDC

Analog or

IB....IE

Inputs I1...I4

Outputs

Q1...Q4 : Relay 8A

1

B

234

CDE

RUN LD

SUN 20 JUL

09:36

1234

Display showing

run mode

Menu/Ok

SR2 B121BD

1

2

Q1

1

2

Q2

1

2

Q3

1

2

Q4

+

-

I1

I2 I3 I4 IB

ID

IC

IE

24VDC

24VDC

24VDC

Analog or

IB....IE

Inputs I1...I4

Outputs

Q1...Q4 : Relay 8A

1

B

234

CDE

RUN LD

SUN 20 JUL

09:36

1234

Menu/Ok

SR2 B121BD

1

2

Q1

1

2

Q2

1

2

Q3

1

2

Q4

+

-

I1

I2 I3 I4 IB

ID

IC

IE

24VDC

24VDC

24VDC

Analog or

IB....IE

Inputs I1...I4

Outputs

Q1...Q4 : Relay 8A

1

B

234

CDE

RUN LD

SUN 20 JUL

09:36

1234

Drawing showing the “UP”

arrow being pressed

Drawing showing the “DOWN”

arrow being pressed