Guide to Physical Installation

4

1.

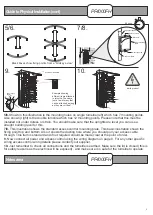

When delivered, the turnstile will either be flat packed on a pallet or shrink wrapped and free standing, if flat packed you must

assemble the turnstile making sure that everything is aligned. Check for any physical damage or defects before you sign!

2.Taking into consideration that the plinth has been prepared correctly and is absolutely level and true,

Lower the

turnstile onto the plinth and visually align.

Make sure that you have pulled all cables through the ducting before bolting

down and that the duct is in the centre of the cable channel in the frame!

3.

Using one M12 fixing, bolt down through one of the holes, it is advisable to blow the excess dust out of the hole before

inserting the bolt.

4.

Now make sure that the turnstile is now aligned perfectly, continue to bolt down through the other holes using the remaining

M12 bolts see below.

Now move on to step 5

The numbers in the text document below relate to the drawings below.

3.

1.

2.

4.

45 mins

Component Identification and Notes:

You should check that you have received the following in your order as they are referred to throughout this

manual (note this can change per turnstile spec i.e. single components are different from double):

M12 Bolt

8 No.

(To bolt turnstile to floor)

PF4000FH

PF4000FH

A

utomatic Turnstile

Single or Double

Duty Cycle: 100%

GB

O&M Manual

Revision 3.0

O&M Manual 1 No.

60 5

10

15

20

25

30

35

40

45

50

55

PF4000FH

Turnstile

(fully erected)

Optional Canopy

Access Control

Mounting Plate

Rotor Arms

Header Cover

Optional Bulk

Head Light

Main Turnstile

Frame

Line the cable

channel up

Cut out showing

cable in channel

When turnstile is level

and secure mark one

of the holes.

Drill a 12mm hole to suit

the M12 stud. Hammer

the stud home then locate

the turnstile hole over the

stud. Once done then fasten

the nut onto the stud.

ACME TOOLS

Now using a 19mm spanner

tighten up all the other nuts.

Manual Release

keys x2