Header mechanism / Manual release guide

PF4000FH

6

Turnstile Maintenance

PF4000FH

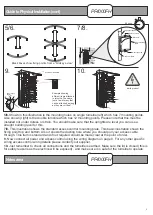

This is a brief overview of the workings and location of parts on the header

mechanism and how to set the turnstile in manual mode:

As stated at the beginning of this manual we recommend a bi-annual service, but at a bare minimum, it is imperative

that you get a service done once every 12 months. This is not a sales tactic in disguise, there is a very serious

health and safety issue/risk associated with not complying to this. Also in order for your equipment to keep

complying with the appropriate legislation.

Before carrying out any maintenance to the installation, disconnect the mains power supply.

1. All moving mechanical header parts should be greased once every 6 months

2. Rotor arm rotation checked and secured.

3. All ground fixing nuts to be checked for corrosion.

4. All ground fixing nuts should be checked for tightness and secure the turnstile two the ground.

5. All electrical connections should be checked in accordance with the latest safety standards.

6. All welds and interconnecting parts should be checked for tightness and security.

7. Any defects or failure in the coating of the turnstile should be noted and reported immediately to the seller or

manufacturing company.

8. Rotor arms should be checked for correct function and angle these should be corrected as needed.

9. The turnstile should be checked for any abnormalities that may cause harm or defect to an object or person.

10. The turnstile control board wiring and general condition should be checked.

11. The turnstile header mechanism should be checked for general condition and mechanical functions to ensure

correct operation.

12. All solenoid's and limit switches should be checked for correct operation.

3.

4.

1.

2.

10 mins

60 5

10

15

20

25

30

35

40

45

50

55

!

Header housing

Manual rotate exit key

Manual rotate entry key

Directional LED’s

Upright bolted

to housing

Exit directional

LED’s

Central rotor

Rotor arms

Turnstile housing

Manual rotation unlock keys

Note: the keys may not be inserted as shown into the diagram above. The

keys will be strapped to the turnstile frame when sent out for delivery.

20x Zoom Showing Key Operation

To Manually release the turnstile

turn the key shown a quater turn

clockwise. Do not force the key it

only takes a quarter turn release!

Open

Close