5

- English -

Start-up

Prior to this observe the following operating steps: Connect the air hose to the unit prior to switching on. We recom-

mend to fit the aeration stones approx. 12 in. (30 cm) below the water surface. Keep the length of the air hoses as

short as possible. Protect the connection cable when burying and connect the transformer to a socket. Air will emerge

from the aeration stones after a short start-up time.

Cleaning

Attention! Dangerous electrical voltage.

Possible consequences:

Death or severe injury.

Protective measures:

Disconnect the power plug prior to reaching into the water and commencing

work.

Disconnect the power supply first, then secure the unit to prevent unintentional switching on. Should the performance

reduce, clean the air intake opening in the base of the housing.

Replacing the diaphragms

Diaphragms need to be replaced occasionally. Always replace diaphragms in pairs, left and right.

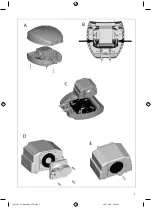

Disconnect the power supply first, then secure the unit to prevent unintentional switching on. Remove the hood by

unscrewing the screws from the unit underside (A). Disconnect the connection hose from the pump heads (B) on the

left-hand and right-hand side. Lift the motor block (C) and remove the diaphragm chamber (D) fitted with four screws.

The membrane can be replaced after loosening the screw and removing the support disk (E). Ensure correct insertion

(note the shape).

Reassemble the unit in the reverse order and put it back into operation.

Wearing parts

Diaphragms are wear parts and are excluded from the warranty.

Storage/Over-wintering

Take the air hoses out of the water and clean. Check the unit for damage and store it in a frost-free environment.

Disposal

Do not dispose of this unit with domestic waste! For disposal purposes, please use the return system provided.

Disable the unit beforehand by cutting off the cables.

Remedy of faults

Malfunction Cause Remedy

Unit does not run

No mains voltage

Transformer defective

Check mains voltage

Replace transformer

Unit does not deliver air

Diaphragms defective

Regulating valve incorrectly set

Valves soiled

Replace diaphragms, clean air slots

Check settings

Clean

Insufficient delivered quantity

Diaphragms defective

Excessive loss in the supply hoses

Regulating valve incorrectly set

Exchange diaphragms

Reduce hose length to a minimum

Check settings

19672-01-14_AquaOxy_USA.pdf 5

28.01.2014 08:54:24