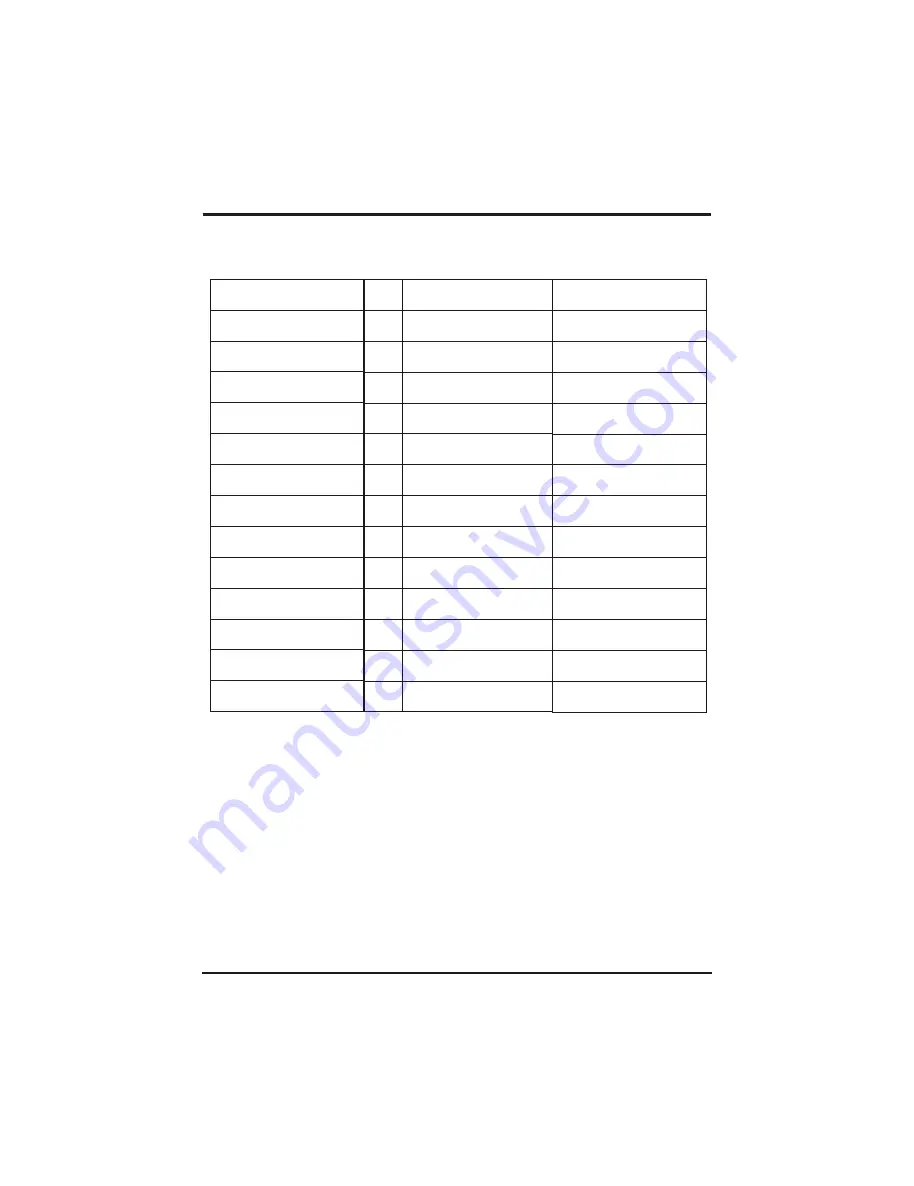

5.2 Trouble Shooting Guide

5. MAINTENANCE AND INSPECTION

26

Temp. is too much different

between water-inlet and outlet

Antifreezing under cooling mode

The primary anti-freezing

protection start.

The second anti-freezing

protection start

Malfunction

Ambient temp. Sensor failure

Communication failure

Water inlet temp. Sensor failure

Water outlet temp. Sensor failure

Pipe temp. Sensor failure

Evaporator temp.Sensor failure

High pressure protect

Low pressure protect

Flow switch failure

E06

E07

E19

E29

Display

P04

E08

P01

P02

P05

P07

E01

E02

E03

Water flow volume not enough,Water

system pressure difference is small

Water flow volume not enough

Ambient temperature is too low

Ambient temperature is too low

Canse

The ambient temp.

sensor

is open or short circuit

Communication failure between

remote wire controller and main board

The water inlet temp. Sensor

is open or short circuit

The water outlet temp.

sensor

is open or short circuit

The pipe temp.

sensor is

open or short circuit

The evaporator temp.

Sensor

is open or short circuit

The exhaust pressure is high ,

high pressure switch action

The suction pressure is low,

Low pressure switch action

No water or litter water

in water system

Check the flow volume,water

system is jammed or not

Solution

Check or change the

ambient temp.

S

ensor

Check the wire connection between

remote wire controller and main board

Check or change the water

inlet temp. Sensor

Check or change the water

outlet temp.

S

ensor

Check or change the pipe temp.

S

ensor

Check or change the

evaporator temp.

Sensor

Check high pressure switch

and cooling return circuit

Check low pressure switch and

cooling return circuit

Check the flow volume ,water

pump is failure or not

Check the flow volume,water

system is jammed or not

All manuals and user guides at all-guides.com