WATER COOLER MODELS

OASIS

®

P8FPM, P12FPM

SUNROC

NFRD8, NFRD12

INSTRUCTIONS

1.

INSPECTION

Inspect the carton and water cooler for evidence of rough handling and concealed damage. Damage claims should be filed with the carrier.

2.

MAINTENANCE

The only maintenance operation required is the removal of dirt and lint from the condenser. Inspection should be made at 3 month intervals.

Disconnect the power supply cord, then clean the condenser with a small stiff non-wire brush when required. Observance of this procedure will insure

adequate air circulation through the condenser so operation is efficient and economical.

3.

OVERLOAD PROTECTION

The compressor motor is equipped with an automatic reset protector which will disconnect the motor from the line in case of an overload.

4.

LUBRICATION

This unit is equipped with a hermetically sealed compressor and requires no additional lubrication. The fan motor on this unit seldom needs oiling,

but if required, a few drops of SAE 10 oil should be used.

5.

TO PUT WATER COOLER INTO SERVICE

a)

Note:

The following states require a licensed plumber to install cooler; AR, GA, MA, MI, OK, RI, SC, SD, TX, VT and WI.

CA, KS, MN, NM and OR allow for a state-registered installer or contractor as well. State and local plumbing codes may prohibit the use of

saddle tapping valves for water line connection in some applications. All connections must conform to applicable plumbing codes.

b)

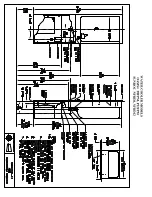

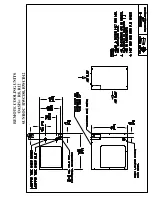

Locate and install plumbing and electrical service in accordance with the roughing-in drawing.

c)

Install wall sleeve. Shim so sleeve is square and plumb. Anchor securely with masonry screws or toggle bolts. Remove the top and bottom

spreaders and discard.

d)

Hang top on wall sleeve with the return flange of the top behind the top flange of the wall sleeve as shown on the dimensional drawing. Fasten

bottom of cooler top in place using two nuts and bolts provided.

e)

Connect slip joint waste adapter, not furnished, to drain fitting and water shut-off valve, not furnished, to supply fitting.

f)

Insert the strainer assembly through the drain hole in the top. Slide the 2” diameter black gasket over the end of the strainer and assemble

tailpiece to the strainer. Draw-up tight to seat gasket. Connect waste trap, not furnished, to the tailpiece. Install cradle for cooling unit to wall

sleeve using 4 screws provided. Install cooling unit in cradle. Assemble connector fittings to water-in and water-out fittings on the cooling unit.

Connect water supply tube from water-in fitting on the cooling unit to the shut-off valve.

g)

Place 1-1/4” diameter black gasket over the bubbler spud. Insert bubbler spud and water line assembly through the hole in the top. Place clear

plastic gasket over spud and the remaining 7/8” diameter black gasket on top of it. Attach bubbler valve to top and connect water line from

bubbler to water-out fitting on cooling unit. Use pipe compound sparingly on male threads only. Do not get pipe compound on inside of lines.

Do not over-tighten fittings. Damage to the cooling unit may result.

h)

Check the available power supply against the cooling unit date plate to assure correct electrical service. Make electrical connections at the

cooling unit junction box.

i)

Turn on water supply to the cooling unit. After water cooler has been filled, as evidenced by the absence of the audible filling sound, draw-off

water from the bubbler until no air bubbles are seen from the bubbler.

j)

Install the grille by placing top flange behind bottom rear of cooler top and the lower inner flange behind bottom wall sleeve flange. Secure grille

to top with screws, provided, at the bottom flange.

6.

TO DISCONTINUE USE OF WATER COOLER

a)

Remove front grille.

b)

Disconnect the power supply.

c)

Close water supply shut-off valve.

d)

Provide container to catch water and remove drain plug.

e)

Remove or open bubbler valve and, if any, the glassfiller valve. Replace plug(s) when draining is complete.

f)

ALWAYS DRAIN ALL WATER WHEN FREEZING TEMPERATURES ARE ANTICIPATED AND BEFORE SHIPPING THE

WATER COOLER.

WARNING

The warranty and the Underwriters’ Laboratories Listing for this machine are automatically voided if this machine is altered, modified, or combined with

any other machine or device. Alteration or modification of this machine may cause serious flooding and/or hazardous electrical shock or fire.

EXCEPT AS SET FORTH HEREIN, THE MANUFACTURER MAKES NO OTHER WARRANTY, GUARANTEE OR AGREEMENT EXPRESSED,

IMPLIED OR STATUTORY, INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

222 East Campus View Blvd. • Columbus, OH 43235 U.S.A.

1-800-950-3226

www.oasiscoolers.com

is a trademark of Oasis International

© 2009 Oasis International

OASIS

®

is a registered trademark of Oasis International

030099-063 Rev L