6

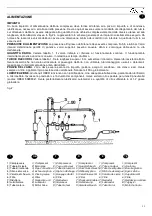

TECHNICAL FEATURES

GB

Table 1

Model

Code

No-load

speed

Power Consumpti

on

Torque

at 6 bar

Steel

threading

Weight

Ø fitting

Noise

Lp

Vibrations

a

h

(rpm)

(W)

(Nl/min.)

(Nm)

(mm)

(Kg)

(mm)

(dB(A))

(m/s

2

)

MGR33

8305528

720

220

430

12

2-5

1.44

40

81.6

< 2.5

MGR55

8305529

400

220

430

21

4-8

1.44

40

81.6

< 2.5

MGR77

8305530

220

220

430

28

4-12

1.44

40

81.6

< 2.5

MSGR33

8305531

650

300

600

16

3-8

1.48

40

82

< 2.5

MSGR55

8305532

350

300

600

30

4-14

1.48

40

82

< 2.5

MTR115

8305527.1

1400

500

1000

13

3-8

3.25

48

77.8

< 2.5

MTR88

8305522.1

600

500

1000

28

4-12

3.9

60

77.8

< 2.5

MTR66

8305525.1

450

500

1000

38

4-16

3.55

48

77.8

< 2.5

MTR44

8305524.1

270

500

1000

64

4-16

3.55

48

77.8

< 2.5

MTR11

8305526.1

100

500

1000

180

6-30

4.2

60

77.8

< 2.5

MP100 CA

8305537.1 300/100

600

800

180

6-30

4

58

77.8

< 2.5

Air inlet MGR, MSGR 1/4” GAS; MTR, MP100 CA 1/2" GAS

Ø inside tube min. MGR 8 mm, MSGR 10 mm, MTR, MP100 CA 13 mm

Fitting chuck MGR, MSGR, MTR44, MTR66, MTR115: B12; MTR88, MTR11, MP100 CA: B16

Noise emission levels determined by using ISO/CD 15744

Levels of vibrations at the handle determined by using ISO 8662

Note:

make sure that the performance features required correspond to those described above, otherwise it will be

necessary to choose a different model from the broad range offered by OBER.

TOOL NOISE

The table of technical specifications indicates the noise level- where the noise level exceeds 85 dB (A) the noise power is

also indicated. Ear protectors must be worn where the noise level exceeds 85 dB (A) at the operator position. We

recommend that you also wear ear protectors below this noise level.

Noise risk and hearing damage are related to the intensity of the noise source and the length of exposure. Noise risk

must be assessed on a case by case basis taking into account these two factors. Measures should be taken to protect

the user against hearing damage in accordance with current Health and Safety regulations.

The formula and table can be used to calculate the daily exposure level for a tool using the use coefficient c. The use

coefficient

c

for a tapping head is between 20 and 40%.

L

eq,d

= L

eq

+ 10 Log

10

T

e

/ T

0

TOOL VIBRATION

The tool in question, tested with regard to the conditions required by the relevant technical standards for feed pressure:

•

ISO 2787 (Rotary and percussive pneumatic tools - performance tests)

for general test indications:

•

ISO 5349 (Mechanical vibration - Guidelines for the measurements and the assessments of human exposure to hand-transmitted vibration

for weighting factors:

•

ISO 5349 (Mechanical vibration - Guidelines for the measurements and the assessments of human exposure to hand-transmitted vibration

characterised by the following level of vibrations:

a

h

= frequency-weighted acceleration <2.5m/s

2

The risk from vibrations is linked not only to the intensity of the source, but also to the exposure time and it is therefore

advisable to evaluate the use of the individual tool during the working day and stick to the regulations in force in individual

countries in order to protect users.

Te= c T

0

T

0

= 8h

L

eq

c

L

eq,

d

85

20%

30%

40%

78,0

79,8

81,0

Dally exposure

level

Summary of Contents for MGR33-55-77

Page 4: ......