Moät soá söï coá thöôøng xaûy ra khi khôûi

ñoäng bôm

Bôm khoâng bôm dung dòch

The pump does not pump

Possible troubles during startup

•

Khoâng khí ñi vaøo ñöôøng oán huùt qua caùc ñaàu noái

Kieåm tra

•

Air entering the suction piping through the fittings:

Check.

•

Khoâng khí bò giöõ laïi trong bôm

Toång löu löôïng cuûa bôm leân lôùn nhaát, neáu khoâng thì nôùi loûng

ñaàu ñaåy cuûa bôm ñeán khi coù dung dòch chaûy ra

•

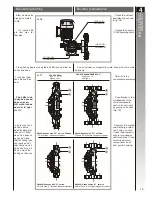

Air trapped inside the pump:

Raise pump flow rate to maximum value, otherwise unscrew discharge valve housing

(pos.14) till the liquid arrives.

•

Chieàu saâu huùt quaù lôùn

Giaûm

•

Reduce it.

Suction lift too high:

•

AÙp suaát bay hôi cuûa dung dòch quaù cao

Taêng aùp suaát thuyû tónh ôû ñaàu huùt cuûa bôm.

•

The vapour pressure of the fluid is too high:

Increase the hydrostatic head on suction side.

•

Ñoä nhôùt dung dòch quaù cao

Laép ñaët ñöôøng oáng huùt coù ñöôøng kính lôùn hôn. Taêng aùp

suaát thuyû tónh ôû ñaàu huùt cuûa bôm

•

The viscosity of the liquid is too high:

Install a suction piping having a larger diameter.Increase the hydrostatic head on

suction side.

•

Ñöôøng oáng huùt bò taéc hoaëc van ñoùng

Kieåm tra laïi

•

Suction piping is clogged or its valves are shut:

Verify.

•

Boä loïc ôû ñaàu huùt bò taéc

Veä sinh.

•

Filter on suction side is clogged:

Clean it.

•

Van bôm bò taéc do caùc chaát baån ñi vaøo töø ñaàu huùt

Thaùo van vaø veä sinh moät caùch caån thaän.

•

Pump valves are stuck because of foreign matters

coming from suction side:

Dismantle the valves and clean them carefully.

NGUYEÂN NHAÂN /

CAUSES

CAÙCH KHAÉC PHUÏC /

SOLUTIONS

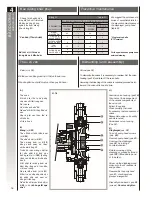

Löu löôïng baát thöôøng hoaëc cao hôn so vôùi yeâu caàu

Flow rate irregular or higher than expected

•

AÙp löïc thuyû tónh ñaàu huùt cao hôn aùp löïc ñaàu ñaåy:

Taêng aùp löïc ñaàu ñaåy baèng caùch laép van taïo aùp löïc ngöôïc

•

The suction hydrostatic head exceeds the discharge pressure:

Increase the discharge pressure by means of a back pressure valve. (OBL, series 300).

•

Van taïo aùp ngöôïc bò taéc ôû vò trí môû hoaëc aùp löïc ñaët quaù

thaáp so vôùi aùp löïc ñaàu huùt

Kieåm tra.

•

Back pressure valve stuck in open position because of foreign matters,

or pressure setting too low respect to the suction head

:

Check.

•

Van cuûa bôm bò keït ôû vò trí môû:

•

Pump valves jammed in open position:

3

14

KHÔÛI

ÑOÄNG

STARTUP

NGUYEÂN NHAÂN /

CAÙCH KHAÉC PHUÏC / SOLUTIONS

Kieåm tra.

Check.

CAUSES