l

Check the oil level

periodically as shown

in fig.

16

.

l

Change the oil every

10.000 operating hours.

l

In case of lower or irregular flow rate, check the valve units

as follows:

l

Refer first to the

pumphead sectiondrawing.

l

Pay attention to the

arrangement of the

valve components;

each valve ball rests

by gravity on its seat

(Fig.

17

).

l

Unscrew the suction

and discharge valve

units, one at a time.

Check their compon-

ents for soundness

and cleanlines. Clean

carefully all valve

components: seat,

ball, guide, housing.

Routine maintenance

H. 17

PROPER ARRANGEMENT OF:

-Valves pos. 15

-Seal pos. 5

Baûo döôõng ñònh kyø

H. 16

15

5

1 5

5

15

5

15

5

l

l

Kieåm tra möùc daàu

ñònh kyø/ xem hình

H.

16

.

Cöù sau10.000

giôø laøm vieäc thì

thay daàu.

LOÃ TRA DAÀU

Oil FIlliNG UP

CÖÛA SOÅ DAÀU

OIL WINDOW

LOÃ THAÙO DAÀU

OIL DRAINING

l

Trong tröôøng hôïp löu löôïng thaáp vaø baát thöôøng, kieåm tra

caùc boä phaän sau :

l

l

l

Tröôùc tieân tham

khaûo hình veõ ñaàu

bôm.

Chuù yù ñeán trình

töï xaép xeáp caùc boä

phaän cuûa van;

moãi moät bi van seõ

naèm ôû vò trí nghæ

(H. 17).

Laàn löôït nôùi oác ôû

caùc ñaàu huùt vaø

ñaàu ñaåy baèng moät

tuoác nô vít. Kieåm

tra caùc boä phaän coù

saïch vaø ôû traïng

thaùi toát khoâng. Lau

chuøi saïch seõ caån

thaän taát caû caùc boä

phaän nhö bi van, oå

ñôõ van, truïc daãn

höôùng vaø thaân van.

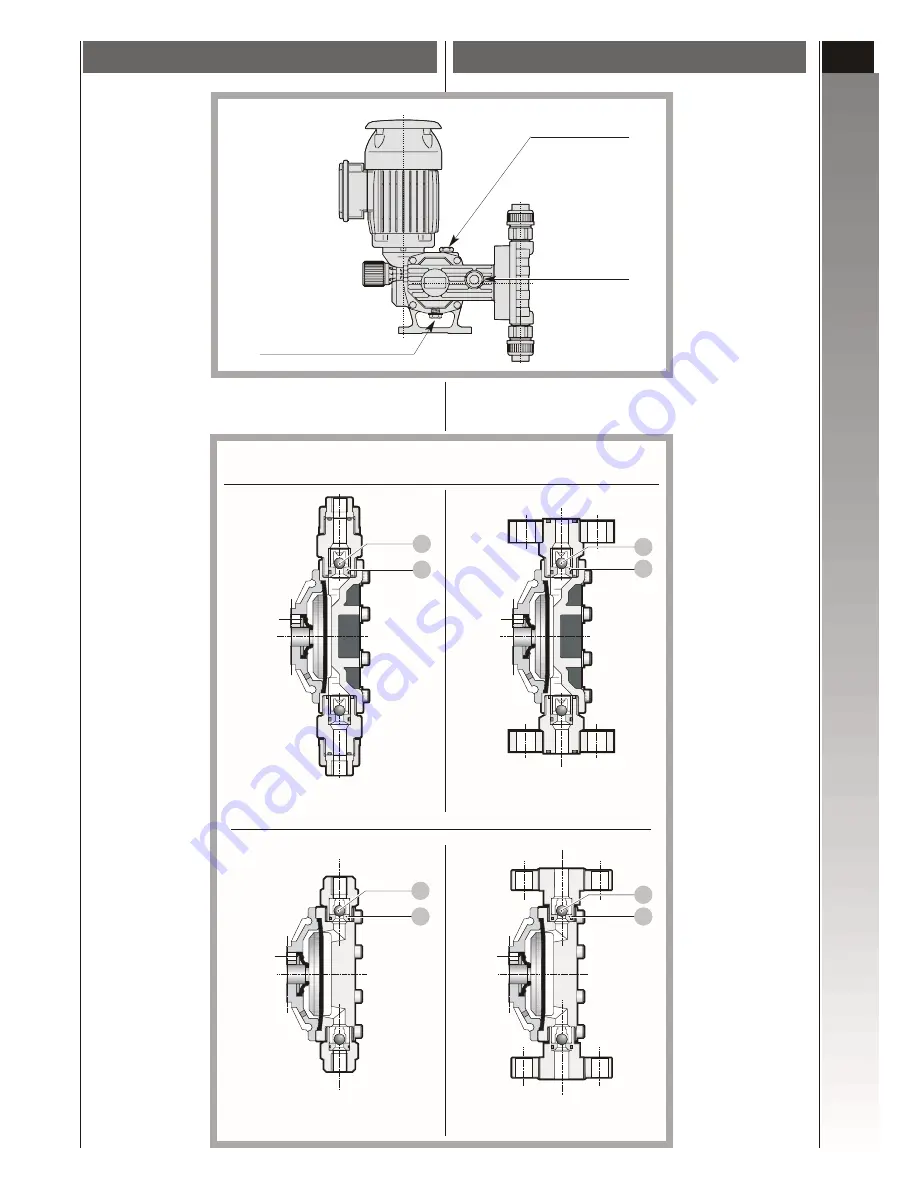

Ñaàu SS316, ñöôïc kyù hieäu "A" , noái bích

A/S/316L heod, "A" execution, flanged connections.

Ñau

à SS316, ñöôc

ï kyù hieu

ä "A" , noiá ren.

A/S/ 316L head, "A" execution, threaded connections.

SAÉP XEÁP ÑUÙNG

- Van vò trí. 15

- Gioaêng vò trí 5

Ñaàu PP, ñöôïc kyù hieäu "PP" , noái ren. PP Head

Ñaàu PP, ñöôïc kyù hieäu "PP" , noái bích

, "PP" execution , threaded connections.

PP head, "PP" execution, ffonged connections.

AVVIAMENT

O

4

15

BAÛO

DÖÔÕNG

MAINTEN\ANCE