1

MOÂ TAÛ BÔM

DESCRIPTION OF THE PUMP

1

LÖU LÖÔÏNG

FLOW RATE

1

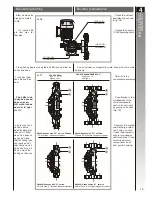

ÑIEÀU CHÆNH BAÈNG TAY

MANUAL ADJUSTMENT

2

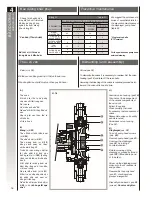

ÑAËC TÍNH ÑOÄNG CÔ PHUÏ THUOÄC VAØO KÍCH CÔÕ BÔM

MOTOR CHARACTERISTICS

2

TÍCH CHAÁT CHUNG

GENERAL CHARACTERISTICS

5

ÑIEÀU KHIEÅN ÑIEÄN “Z9”

ELECTRIC ACTUATOR “Z9”

15

ÑIEÀU KHIEÅN ÑIEÄN

ACTUATOR

4

BAÛO DÖÔÕNG ÑÒNH KYØ

ROUTINE MAINTENANCE

12

BAÛO DÖÔÕNG PHOØNG NGÖØA

PREVENTIVE MAINTENANCE

13

THAÙO LAÉP VAN

DISMANTLING (AND REASSEMBLY)

13

SÖÏ COÁ KHI VAÄN HAØNH

OPERATING TROUBLES

14

BAÛO DÖÔÕNG

MAINTENANCE

3

TRÖÔÙC KHI KHÔÛI ÑOÄNG

BEFORE STARTUP

10

KHÔÛI ÑOÄNG BÔM

PUMP STARTUP

10

MOÄT SOÁ SÖÏ COÁ THÖÔØNG XAÛY RA KHI KHÔÛI ÑOÄNG BÔM

POSSIBLE TROUBLES DURING STARTUP

11

KHÔÛI ÑOÄNG

STARTUP

CHÆ DAÃN LAÉP ÑAËT BÔM ÑUÙNG QUY CAÙCH

2

INSTRUCTIONS FOR A CORRECT INSTALLATION OF THE PUMP

3

ÑÖÔØNG OÁNG HUÙT

SUCTION LINE

3

BOÄ LOÏC ÑAÀU HUÙT

SUCTION SIDE FILTER

4

ÑÖÔØNG OÁNG HUÙT VÔÙI DUNG DÒCH COÙ ÑOÄ NHÔÙT

SUCTION PIPING FOR VISCOUS LIQUIDS

5

ÑÖÔØNG OÁNG ÑAÅY

DISCHARGE LINE

6

VAN AN TOAØN

RELIEF VALVE

6

LAÉP ÑAËT THIEÁT BÒ TIEÂU XUNG

INSTALLATION OF THE PULSATION DAMPER

7

LAÉP ÑAËT ÑOÀNG HOÀ ÑO AÙP LÖÏC

INSTALLATION OF THE PRESSURE GAUGE

8

HEÄ THOÁNG LAÉP ÑAËT CHUAÅN

STANDARD PLANT ARRANGEMENT

8

TRA DAÀU HOÄP GIAÛM TOÁC

CASING OIL FILLING UP

9

LAÉP ÑAËT

INSTALLATION

MUÏC

LUÏC

INDEX