Vieäc laép ñaët ñuùng quy caùch vaø kích thöôùc oáng huùt ñaëc bieät

quan troïng ñeå vaän haønh bôm an toaøn.

Caùc yeáu toá sau caàn phaûi ñöôïc tính ñeán:

A)

Ñöôøng kính trong cuûa oáng ñöôïc choïn

theo löu löôïng bôm (Baûng

C

).

Caùc ñaàu noái bôm coù kích thöôùc lôùn hôn

cho caùc öùng duïng khaùc nhau.

B) Chieàu daøi cuûa oáng.

Chieàu daøi oáng huùt caøng ngaén caøng toát.

Vaø chieàu daøi phuø hôïp nhaát theo baûng

C

:

Chieàu saâu huùt lôùn nhaát laø 1,5 m

Toång chieàu daøi cuûa oáng huùt: 2,5m

C) Sô ñoà kieåu laép ñöôøng oáng huùt.

Xem hình minh hoaï H.

7

n

n

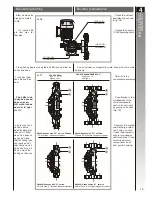

Maët baèng laép ñaët thieát bò phaûi saïch seõ vaø an toaøn cho vieäc vaän

haønh vaø baûo döôõng thieát bò. Chuù yù ñeán

khoaûng khoâng ôû phaàn ñaàu huùt, ñaàu ñaåy

cuûa bôm vaø nuùm ñieàu chænh (H

6

).

Neáu bôm ñöôïc laép ñaët ôû ngoaøi trôøi thì

caàn thieát phaûi coù maùi che, ñaëc bieät laø khi

bôm ñuôïc keát noái vôùi caùc thieát bò khôûi

ñoäng ñieän vaø caùc thieát bò ñieàu khieån

khaùc.

Ñaàu bôm baèng nhöïa PVC chæ coù theå

laøm vieäc ôû nhieät ñoä moâi tröôøng vaø nhieät ñoä dung dòch toái ña laø

0

40 C. Neáu caàn thieát thì coù theå söû duïng theâm thieát bò che bôm

khoûi aùnh naéng maët trôøi vaø kieåm tra nhieät ñoä cuûa dung dòch.

Chæ daãn laép ñaët ñuùng quy caùch

Provide with adequate clearance areas and safe access for

operation and maintenance, in particular

in front of the hydraulic side and of the

adjustment knob (fig.

6

).

If the pump is installed outdoors, a

shelter is recommended, specially

when the pump is equipped with electric

actuators or other delicate devices.

PP pump heads can work properly only

at ambient temperature and metered

0

liquid temperatures below 40 C. If neces sary, provide suitable

protection from sun rays and check the temperature of the

metered liquid.

Instructions for a proper installation

H. 6

HYDRAULIC

SIDE

ADJUSTMENT

SIDE

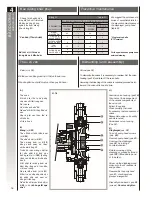

A proper installation and sizing of the suction line are of particular impor-

tance for a correct operation of the pump.

The following factors shall be taken into account:

A) Pipe inner diameter

The pipe inner diameter will be chosen as a

function of the pump flow rate (see table

C

).

The pump connections are oversized, in

order to cover all applications.

B) Length of piping

Suction piping is to be as short as

possible. Following the indications of

table

C

it issuggested:

l

Max suction lift 1,5 metres

l

Total length 2,5 metres

(upright plus horizontal)

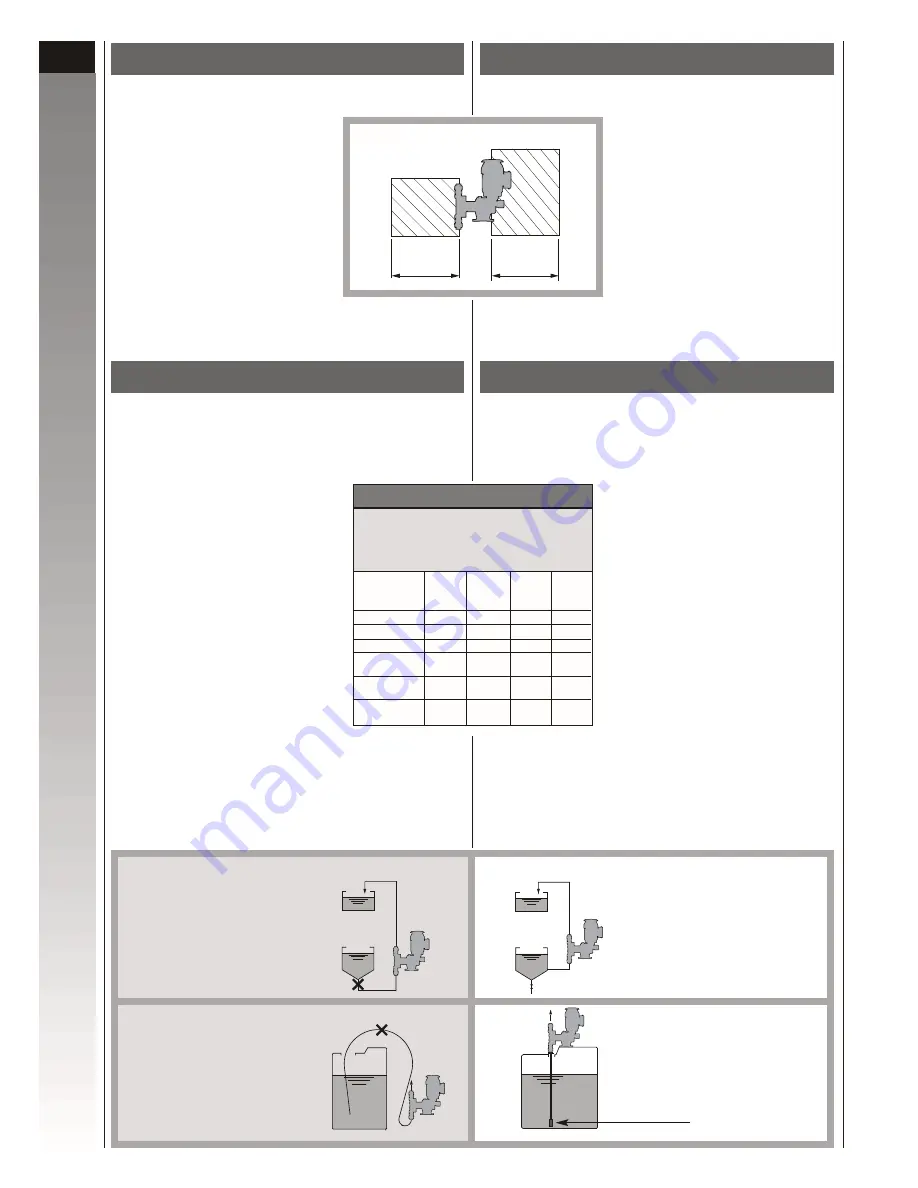

C) Arrangement of the suction line

For the arrangement of the suction line see fig.

7.

Suction line

Ñöôøng oáng huùt

Baûng C

Table C

0÷15

4x6

-

-

-

0÷30

6x10

-

1

/

4

"

-

0÷125

-

DN 10

3

/

8

"

φ

16

0÷155

-

DN 15

1

/

2

"

1/2" ANSI

0÷260

-

DN 20

3

/

4

"

25

3/4" ANSI

0÷420

-

DN 25

1

"

32

1" ANSI

Moái töông quan giöõa löu löôïng

vaø kích thöôùc oáng

Relationship between flow rate and pipe size

LÖU LÖÔÏNG

FLOW RATE

L/h

PIPE WITH

FITTINGS

FLANGED

PIPE

THREADED

PIPE

PVC GLUED

PIPE

H. 7

VAN LOÏC

FILTER FOOT VALVE

KÍCH THÖÔÙC LAÉP ÑAËT

/ ASSEMBLING AREA

Ñuùng

Right

Ñuùng

Right

Sai

Deã bò taéc bôm

Wrong

Risk of clogging of pump valves

Sai

Taïi ñIeåm cao nhaát oáng daãn dung

dòch bò gaãy

Wrong

In the highest point the fluid vein

breaks

LAÉP

ÑAËT

INSTALLATION

2

6

20

φ

φ

φ

PHAÀN

T

HUYÛ

L

ÖÏC

PHÍA

ÑIEÀU

CHÆNH

ÑAÀU NOÁI

OÁNG

OÁNG NOÁI

BÍCH

OÁNG NOÁI

REN

OÁNG NOÁI

NHÖÏA

800

700