OBO Bettermann

24 | EN

Mounting the product

4 7

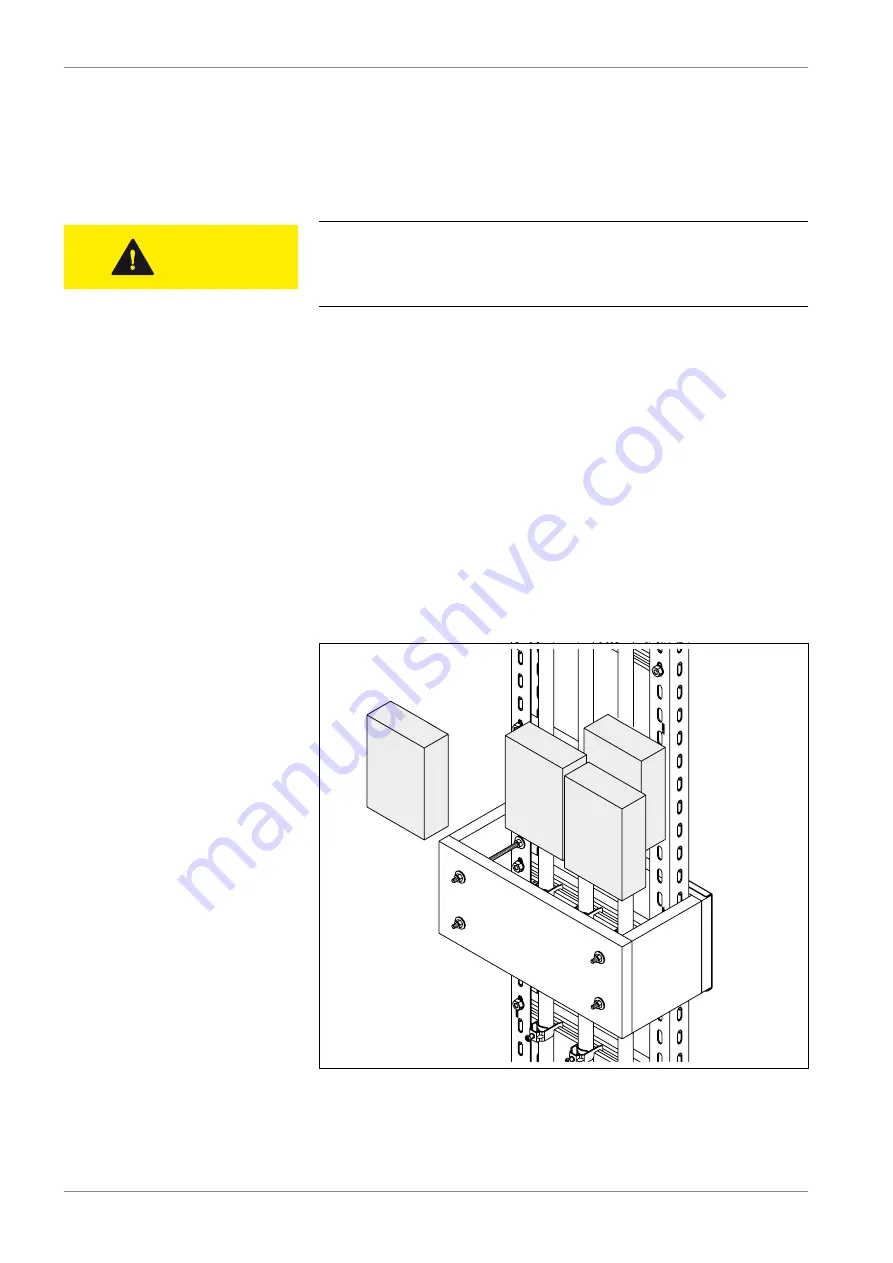

Filling the housing with foam blocks and/or fire

protection foam

Suitable for type ZSE90-25-11 L, ZSE90-35-11 L, ZSE90-45-11 L, ZSE90-

25-17 L, ZSE90-35-17 L, ZSE90-45-17 L, ZSE90-55-17 L,

ZSE90-65-17 L, ZSE90-21-17 LH, ZSE90-31-17 LH, ZSE90-41-17 LH,

ZSE90-51-17 LH, ZSE90-61-17 LH

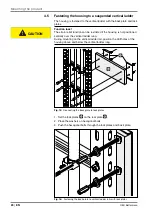

CAUTION

Function loss!

If improperly filled, the strain relief function can be impaired. Maintenance

of electrical function is not then guaranteed. Fill the housing fully with fill-

ing material. Seal cavities and residual joints on the top and bottom side.

The housing on the suspended vertical ladder as well as the hous-

ing directly fastened to the wall can be filled with PYROPLUG

®

Block

FBA-B200-14 foam blocks and PYROSIT

®

NG fire protection foam. Spac-

es with low or no assignment are filled with foam blocks. Residual joints

between the foam blocks must be filled with FSB-SP fire protection filler.

The remaining spaces are filled with fire protection foam. The housing

can also be filled completely with fire protection foam.

In the following, it is shown how the housing on the suspended vertical

ladder is filled. The housing directly fastened to the wall is filled in the

same way with foam blocks and/or fire protection foam.

Note!

To prevent the foam blocks from falling out or to prevent the fire protection

foam from expanding too far, the housing can first be sealed from below,

e.g. with adhesive tape. After mounting, adhesive tape or similar aids

must be removed again.

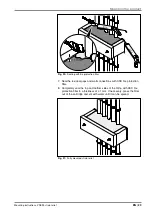

Variant A: Filling with foam blocks and fire protection foam

Fig 22:

Filling the housing with foam blocks

1. Place the foam blocks vertically in the housing.