5 | EN

Screw-on cable tray systems

About these instructions

1 About these instructions

1 1

Target group

These mounting instructions are intended for the following target group:

– Engineers and architects charged with the planning of cable support

systems with cable trays.

– Electrically trained specialists charged with installing cable support

systems and cable trays.

1 2

Relevance of these instructions

These instructions are based on the standards valid at the time of

compil ation (June 2021).

Please read the instructions carefully before starting mounting. We will

not accept any warranty claims for damage caused through non-obser-

vance of these instructions.

Any images are intended merely as examples. Mounting results may look

different.

In these instructions, cables and lines are referred to simply as cables.

1 3

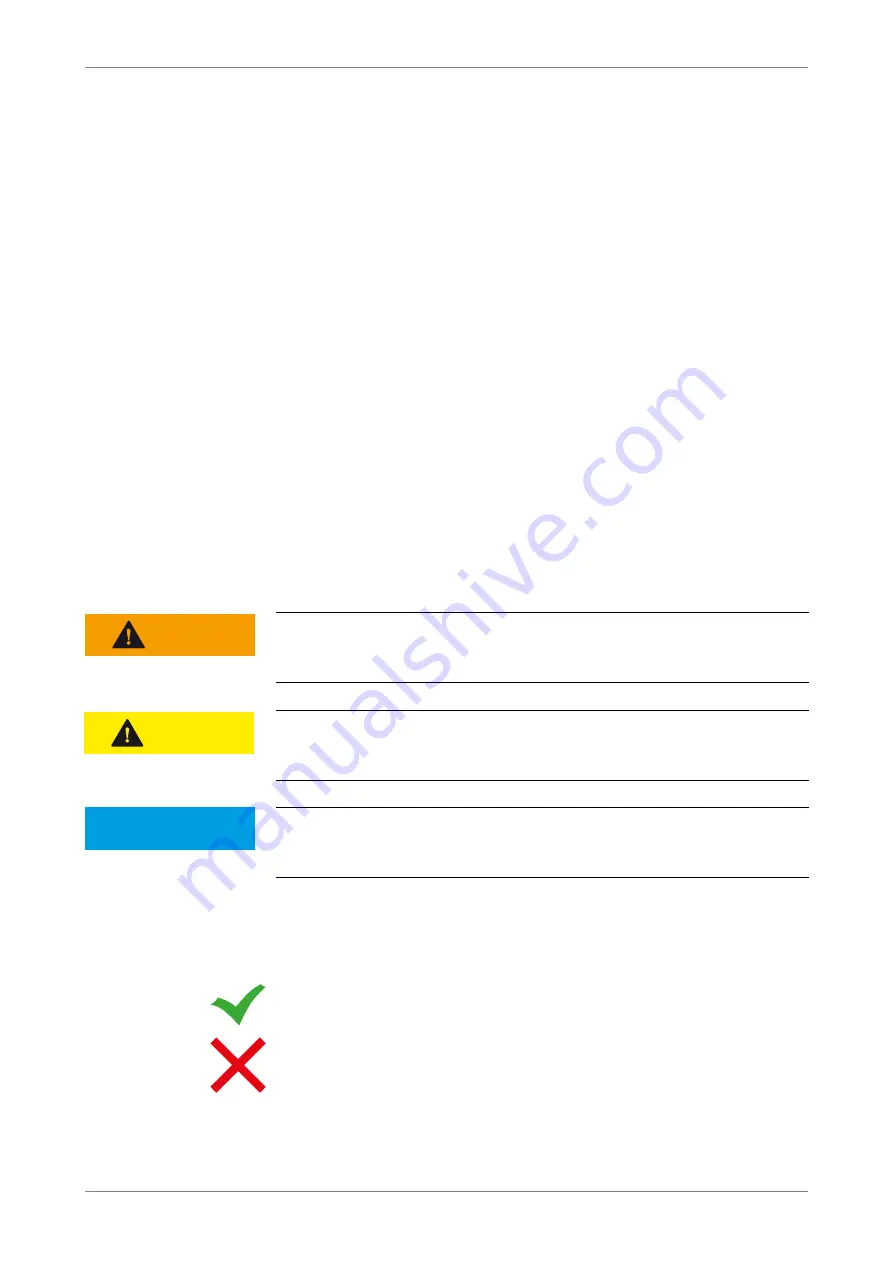

Types of warning information

Type of risk!

Shows a risky situation. If the safety instruction is not observed, then

serious or fatal injuries may occur.

Type of risk!

Shows a risky situation. If the safety instruction is not observed, then

medium or minor injuries may occur.

Type of risk!

Shows a hazardous situation. If the safety instruction is not observed,

then damage to the product or the surroundings may occur.

Note!

Indicates important information or assistance.

1 4

Depiction conventions

Correct design

Incorrect design

WARNING

CAUTION

ATTENTION