OBO Bettermann

78 | EN

Disposal

11 Disposal

Note!

Comply with the local and national waste disposal regulations.

11 1

Disposal during mounting

– Residual material of the duct system (also with coating): As old metal

– Packaging: As household waste

– Protective film: As household waste

11 2

Disposal during building demolition

– Residual material of the duct system (also with coating): as old metal

11 3

Disposal after a fire

Parts of the fire protection duct system that have been subjected to fire

damage must be completely removed and disposed of. The cables must

also be replaced and reinstalled.

We recommend obtaining the advice of the local fire damage restorer

during disposal.

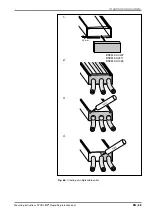

CAUTION

Danger from corrosive effect of fire residues!

If there is a fire in the interior of the duct, the burned cable insulation will

create corrosive gases, which have an irritant and corrosive effect. Before

opening and disposing of duct sections that have been subjected to a fire,

wear breathing protection and protective clothing.

Use breathing protection with a filter or breathing

protection which is independent of the ambient air.

Wear a protective suit (e.g. disposable protective suit).

Wear protective gloves.

Wear protective glasses.