15

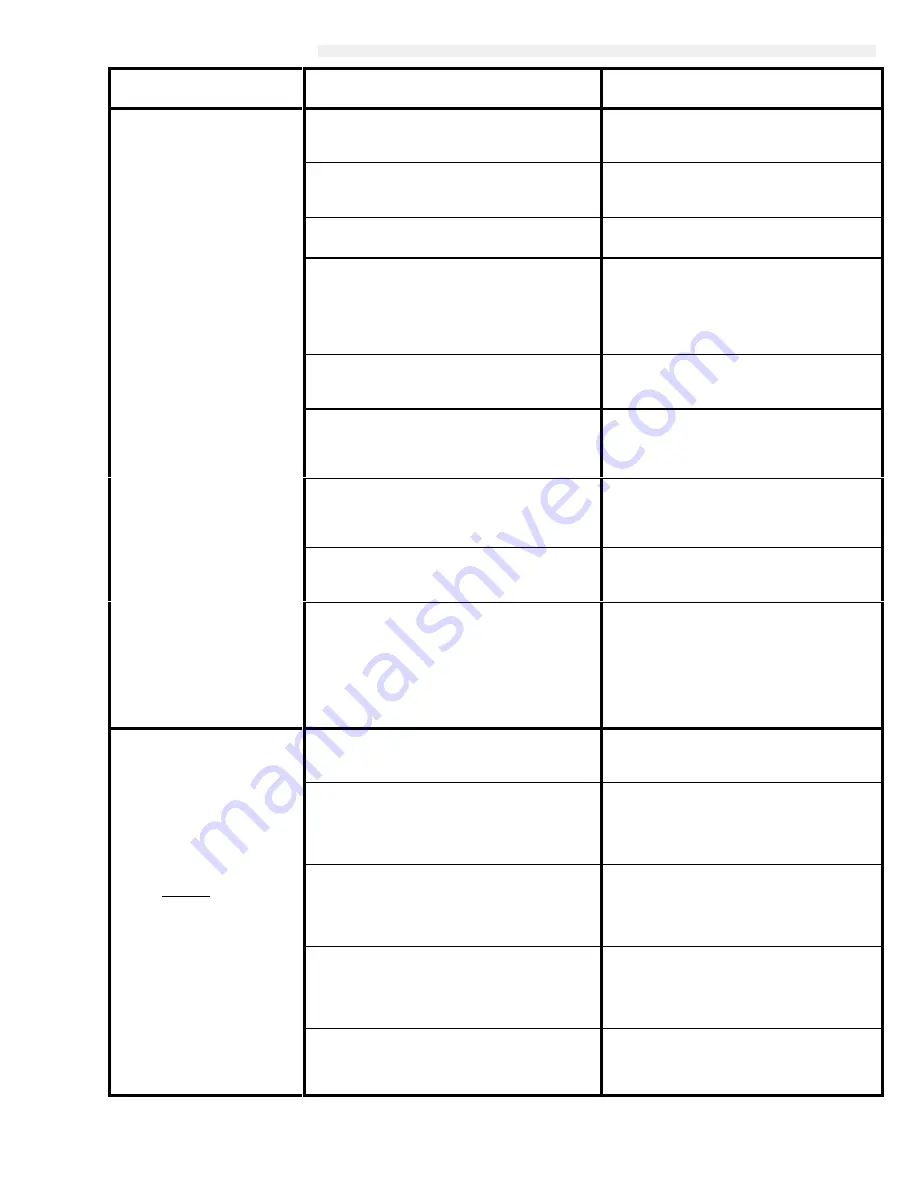

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK refer to this column

1

. Check leads from bridge (308) to motor to be

sure they are securely fastened and properly

mated.

1. Replace loose terminals; crimp to leads.

Be sure male terminal blades are straight

and firmly connected to mating part.

2. Check G1 and G2 connections between cir-

cuit board (79) and bridge (308) for damage

or loose terminals.

2. Clean circuit board male terminals. Re-

place loose or damaged terminals. Se-

curely reconnect leads.

3. Check for loose motor brush lead connec-

tions and terminals. See page 23.

3. Tighten terminal screws. Replace brushes

if leads are damaged. See page 23.

4. Check brush length which should be 1/2”

minimum. See page 23.

NOTE:

The brushes do not wear at the same

rate on both sides of the motor. Check both

brushes.

4. Replace brushes. See page 23.

5. Check for broken or misaligned motor brush

springs. Rolled portion of spring must rest

squarely on top of brush. See page 23.

5. Replace spring if broken. Realign spring

with brush. See page 23.

6. Check motor brushes for binding in brush

holders. See page 23.

6. Clean brush holders. Remove carbon with

small cleaning brush. Align brush leads

with slot in brush holder to assure free ver-

tical brush movement.

7. Check motor armature commutator for burn

spots, gouges and extreme roughness. Re-

move motor cover and brush inspection

plates to check. See page 23.

7. Remove motor and have motor shop resur-

face commutator if possible. See page 32.

8. Check motor armature for shorts using arma-

ture tester (growler) or perform spin test. See

page 20.

8. Replace motor. See page 32.

9. Check bridge (308) by substituting with a

good bridge or performing bridge test. See

page 21.

CAUTION:

Do not perform this check until

motor armature is determined to be good. A

bad motor armature will immediately burn out

a good bridge.

9. Replace bridge. See page 25.

Condition B

(continued)

Both lamps off

1. Check circuit breaker (309) button to be sure

it has not popped up.

1. Depress button to reset. If circuit breaker or

fuse continues to open, see “Electrical

Short”, page 19.

REFER TO THE WIRING

DIAGRAM ON PAGE 185

TO IDENTIFY TP POINTS.

2. Check power supply cord (31 1). Disconnect

TP6 female (neutral) and TP1 female and

connect volt meter to these leads. Plug in

sprayer. Meter should read 105 to 125 VAC.

Unplug sprayer. Reconnect TP1.

2. Replace power supply cord. See page 24.

NOTE:

Connect the volt meter

to the terminal not the wire

which you disconnect from the

terminal.

3. Check ON/OFF switch (303). Disconnect

TP2 and connect volt meter to TP6 female

and TP2 male. Plug in sprayer and turn

ON

.

Meter should read 105 to 125 V AC. Turn off

and unplug sprayer. Reconnect TP2.

3. Replace ON/OFF switch. See page 24.

4. Check jumper wire (306). Disconnect TP3

and connect volt meter to TP6 female and

TP3 female. Plug in sprayer and turn on. Me-

ter should read 105 to 125 VAC. Turn off and

unplug sprayer. Reconnect TP3.

4. Replace jumper wire. See page 26.

5. Check circuit breaker (309). Connect volt me-

ter to TP6 female and TP4. Plug in sprayer

and turn

ON

. Meter should read 105 to 125

VAC. Turn off and unplug sprayer.

5. Replace circuit breaker. See page 25.

MOTOR WON’T OPERATE

Diagnosing circuit board

indicator lamps.

The normal

condition is red lamp on, clear

lamp

on when board is telling

pump to run.

Follow

Pressure Relief Pro-

cedure W arning

. Remove

gun from hose. Remove pres-

sure control cover. Check for

faulty condition of circuit

board lamps.

Condition A

Both lamps on; pump won’t

operate and motor is not

running