23

308–030

MOTOR & CAPACITOR

To reduce the risk of serious bodily injury, al-

ways follow the Pressure Relief Procedure

Warning on page 14 before checking or re-

pairing any part of the spray system.

WARNING

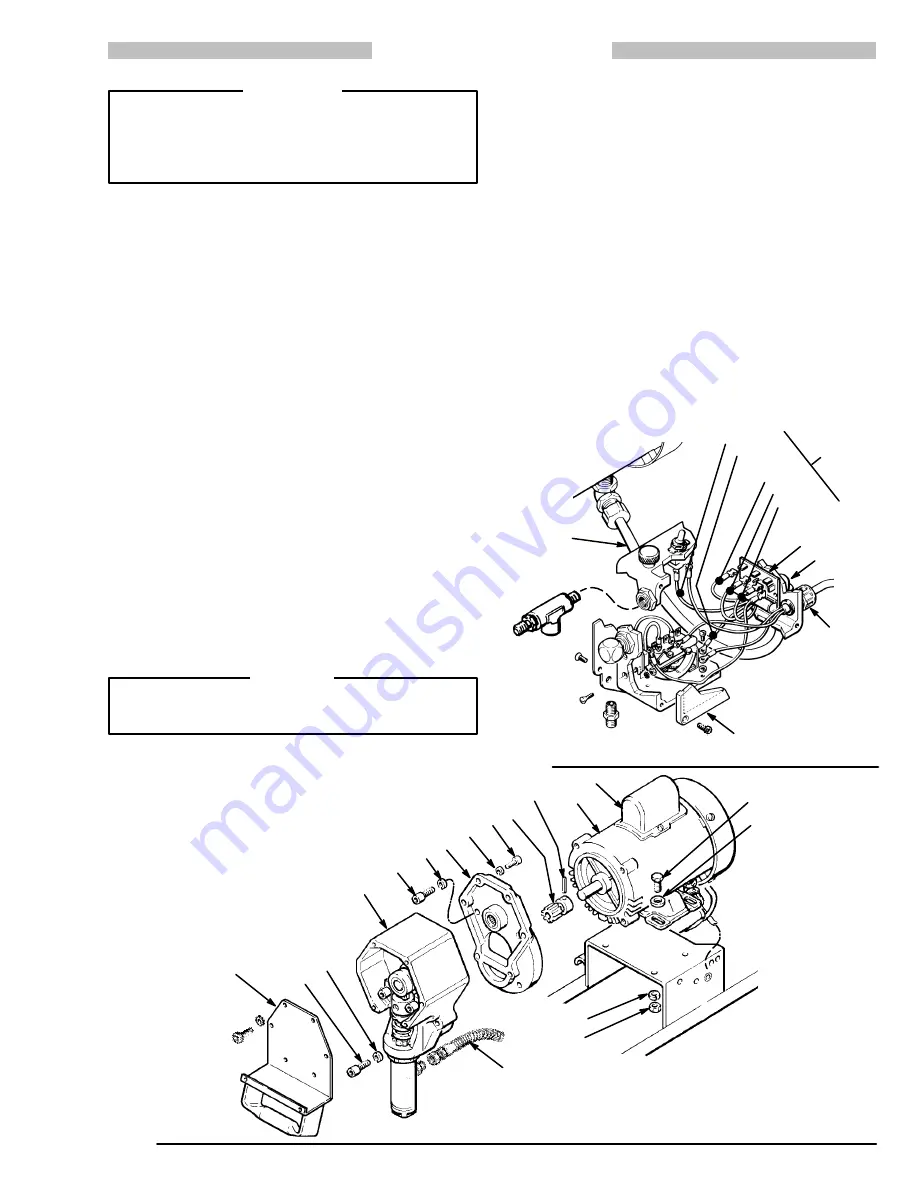

NOTE: Refer to Fig 20 except where noted.

1. Remove the sprayer’s shroud and the lift han-

dle (2).

2. Disconnect the hose (26) from the displace-

ment pump.

3. Remove the screws (51 & 8b). Pull the drive

housing assembly (A) off the motor housing

(B).

4. Remove the screws (8c) and pull the motor

housing (B) off the motor (13).

5. Drive out the pin (61). Remove the gear (60).

6. Remove the pressure control cover (7). Dis-

connect the motor leads. See Fig 21.

7. Unscrew the nut on the conduit (13f). Unscrew

the bushing (91). See Fig 21. Gently pull the

conduit away from the pressure control and

pull the leads out one at a time.

CAUTION

Always pull the motor leads one at a time to

avoid loosening the terminals.

8. Remove the motor mounting screws (38). Lift

the motor off the frame.

9. Install the new motor in

the reverse order.

10. Clean the gear (60) and inspect it for wear or

damage. Replace if necessary. Secure the

gear with the pin (61). Apply molybdenum dis-

ulfide spray lubricant to the gear, allow to dry,

and then apply industrial-grade, heavy-duty,

extreme-pressure, lithium-soap grease.

NOTE: A circuit board (13b) is included with a

new motor. See page 18 for installation.

Capacitor

1. Remove the cover of the capacitor (13a). See

Fig 21. Remove the flag connectors from the

old capacitor. Connect the flag connectors to

the new capacitor and replace the cover.

NOTE: The replacement capacitor includes a

new resistor, installed.

GREEN &

YELLOW

RED

PINK

Fig 21

BLACK

BROWN

MOTOR

LEADS

7

308

13f

13b

91

Fig 20

61

13

60

8b

8a

8d

8c

A

50

51

26

38

84

13a

2

B

39

40

Summary of Contents for PRO 301

Page 29: ...29 308 030 NOTES...

Page 30: ...30 308 030 NOTES...