Avoid these Situations For Your Personal Safety

[16] UV Lamp Hazard

Avoid printing at a height

greater than measured as

this causes excessive

emissions of UV light

and ink mist.

Keep a distance of at

least 1 m (3 ft.) to the UV

light when printing.

Avoid looking at the UV

lamps, especially if you

are seated at the same

level as the carriage. Do

not sit within 5 meters

(17 feet) of the carriage

path.

Also do not touch the UV

lamp assembly or the

surrounding guard as

they will be hot and may

result in burns of the

skin.

Residual Safety Risks

Your Océ Arizona printer is engineered to minimize machine components and operating

procedures that may compromise operator safety. However, in order to maintain some machine

operations and functionality, certain compromises are required. The following table documents

some of these residual hazards. By making the operator aware of the potential risks, we hope to

ensure maximum safety in the operation of this printer.

Caution

: there may be a time lag between when a print job is issued and when the gantry

movement actually begins as the UV lamps must warm up first. Movement can start many

minutes after a print job is sent.

Arizona Printer Residual Risks

Residual Risk Area

Hazard

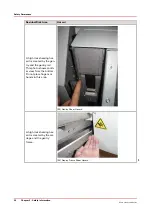

A high risk crushing haz-

ard is created by the

movement of the car-

riage and gantry sup-

ports. Keep hands away

from this area unless the

printer power is off.

[17] Carriage guard and 45° guard on Gantry Supports

4

Safety Awareness

Chapter 3 - Safety Information

27

Océ Arizona 1200 Series

Summary of Contents for arizona 1240 GT

Page 1: ...User guide Oc Arizona 1200 Series Revision 3010121377...

Page 6: ...Contents 6 Oc Arizona 1200 Series...

Page 7: ...Chapter 1 Introduction...

Page 11: ...Chapter 2 Product Compliance...

Page 15: ...Chapter 3 Safety Information...

Page 34: ...Roll Media Safety Awareness 34 Chapter 3 Safety Information Oc Arizona 1200 Series...

Page 35: ...Chapter 4 How to Navigate the User Interface...

Page 56: ...Software Update Module 56 Chapter 4 How to Navigate the User Interface Oc Arizona 1200 Series...

Page 57: ...Chapter 5 How to Operate Your Oc Arizona Printer...

Page 78: ...Media Registration 78 Chapter 5 How to Operate Your Oc Arizona Printer Oc Arizona 1200 Series...

Page 79: ...Chapter 6 Operating the Oc Arizona 1200 XT...

Page 85: ...Chapter 7 Roll Media Option...

Page 109: ...Chapter 8 Static Suppression Option...

Page 113: ...Chapter 9 How to Manage a White Ink Workflow...

Page 157: ...Chapter 10 Ink System Management...

Page 161: ...Chapter 11 Troubleshooting...

Page 163: ...Chapter 12 Printer Maintenance...

Page 207: ...Appendix A Application Information...