REGULATORS

ZX SECOND STAGE

©2002 Design, 2005

PG-5

OCEANIC

®

Product Service Guide

Doc. 12-2808-r01 (2/19/05)

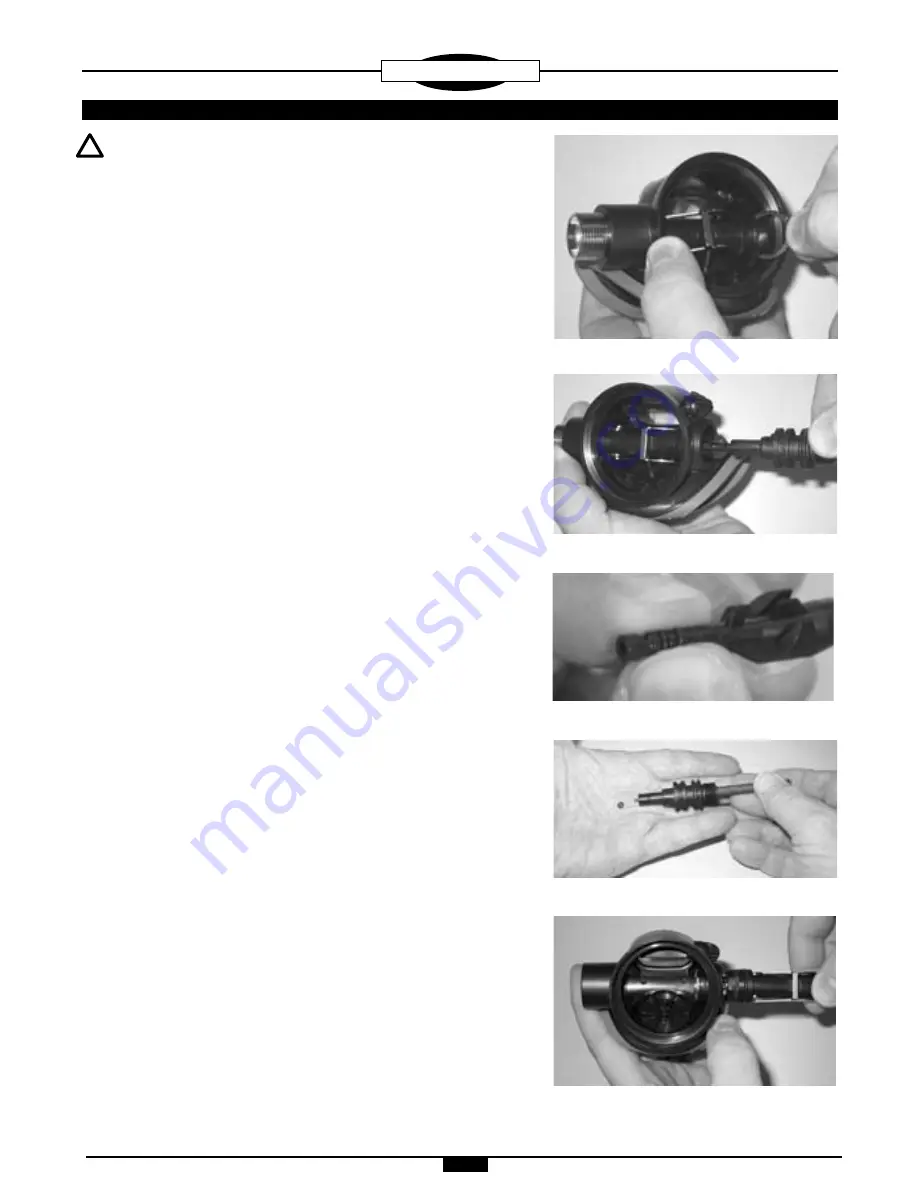

Fig. 5

Fig. 8

NOTE: Removal of the SPRING FOLLOWER (16) from the

ADJUSTMENT SHAFT (15) should not be necessary unless

it is broken or needs to be replaced. In this case remove it by

holding the ADJUSTMENT SHAFT in one hand and turning

the SPRING FOLLOWER clockwise with your other hand.

Note that the Thread is left handed.

11. Examine the ADJUSTMENT SPRING (17) with a magnifier and

compare it with a new one to ensure correct tension and length.

Discard it if found to be distorted, weakened, or corroded.

12. Remove the ADJUSTMENT TUBE RETAINER (9) by grasping

the Top with your fingers and lifting it straight up and off the

ADJUSTMENT TUBE (Fig. 4)

13. Remove the ADJUSTMENT TUBE/SHAFT Assembly (20/15) by

grasping the Threaded portion with your fingers and pulling it

straight out of the VALVE HOUSING (26) (Fig. 5).

The DEMAND LEVER (27) will drop as the Assembly is with-

drawn.

14. If the POPPET (24) does not come out, tip the HOUSING to one

side and gently tap it in your hand to remove the POPPET.

15. Remove the POPPET SEAT (25) from the POPPET (24) with the

use of a dental pick. Discard and DO NOT attempt to reuse it.

16. Remove the POPPET O-RINGS (22/23) by squeezing them with

your fingers and working them over the End of the POPPET (24)

(Fig. 6). DO NOT use tools to remove them. Discard the O-

RINGS and DO NOT attempt to reuse them.

17. Remove the ADJUSTMENT TUBE O-RING (19) from the AD-

JUSTMENT TUBE (20) and inspect it for any signs of decay.

Discard it if found.

18. Remove the BALANCE SHAFT O-RING (21) located inside the

ADJUSTMENT TUBE (20) by pressing it out with a wooden

dowel or dull punch (Fig. 7). Discard the O-RING and DO NOT

attempt to reuse it.

19. Using a wooden dowel, press the VALVE HOUSING (26) straight

through the HOUSING (4) and out through the Adjustment

Assembly opening in the opposite side (Fig. 8).

20. Examine the DEMAND LEVER (27) to ensure that it is not bent

or distorted in any way. If distortion is found and it is necessary

to remove the DEMAND LEVER, proceed as follows:

Using your fingers, press outward on one Prong of the DEMAND

LEVER to disengage it from the VALVE HOUSING (26), repeat

to disengage the other Prong, and lift the DEMAND LEVER up

and off the VALVE HOUSING.

Fig. 6

Fig. 7

Fig. 4