DISCOVER

D3

.

INSTALL & OPERATION MANUAL

11

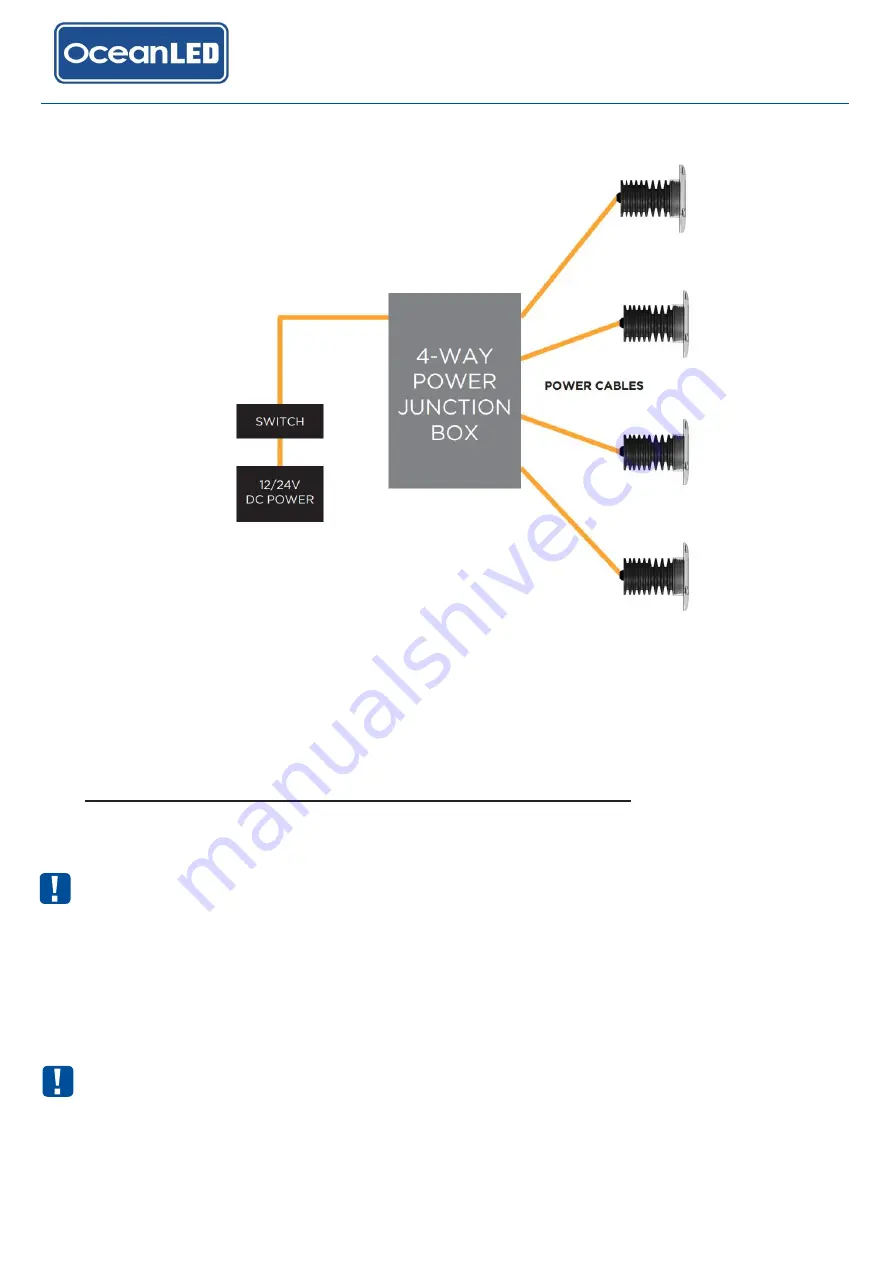

Wiring Schematic with Power Junction Box:

4.3 FINALISING THE INSTALLATION

The Discover D3 features a polymer front bezel that protects against corrosion as well as insulates against conductive

hull types. The front face of the bezel is pre-coated with a specialized Tritonium® coating which helps to prevent marine

growth from adhering to it. The light body is constructed from Hard Anodised Aluminium and does not require further

protection.

No paint or any type of anti-fouling agent should be applied to the bezel

, as damage may occur to the

light due to chemical incompatibility and can affect the performance of the light and will immediately void the

warranty.

Please do not use any un-authorised cleaning products to remove excess paint or antifoul off the bezel.

OceanLED recommends using Isopropyl Alcohol (IPA) only.

4.4 TEST YOUR INSTALLATION

Always test the lights

BEFORE

the vessel goes back into the water. At this final stage make sure all of the system is

operational. If you have any issues, please contact your local OceanLED representative.

Never install a new light fixture then leave the vessel in the water unchecked for several days.

When the vessel is placed in the water, immediately check for leaks. Note that very small leaks may not be

readily observed. It is best not to leave the vessel in the water for more than 3 hours before checking it again.

If there is a small leak, there may be considerable bilge water accumulation after 24 hours. If a leak is

observed, you must TAKE ACTION IMMEDIATELY to prevent damage.