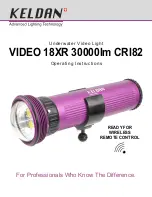

INSTALLATION (QUICK START GUIDE):

SUSTAINABILITY

OceanLED is committed to a sustainable future. Through constant product and design innovation, establishing better

working practices, and evaluating our supply chains, we are able to take measurable steps to creating true sustainability

in our business.

1.

Test light(s) before fitting.

2.

(1) Apply a generous amount of sealant to the rear

of the mounting tube assembly’s bezel to ensure a

complete unbroken seal around the light. Make sure

sealant fills in the recess groove on the reverse of

the light bezel. There should be a continuous and

unbroken bead of sealant.

3.

To ensure the correct light orientation, position the

light with the red arrow sticker (3) on the rear lid

pointing up, perpendicular to the waterline. When

viewing from the front, make sure the OceanLED

logo (2) remains horizontal with the waterline.

4.

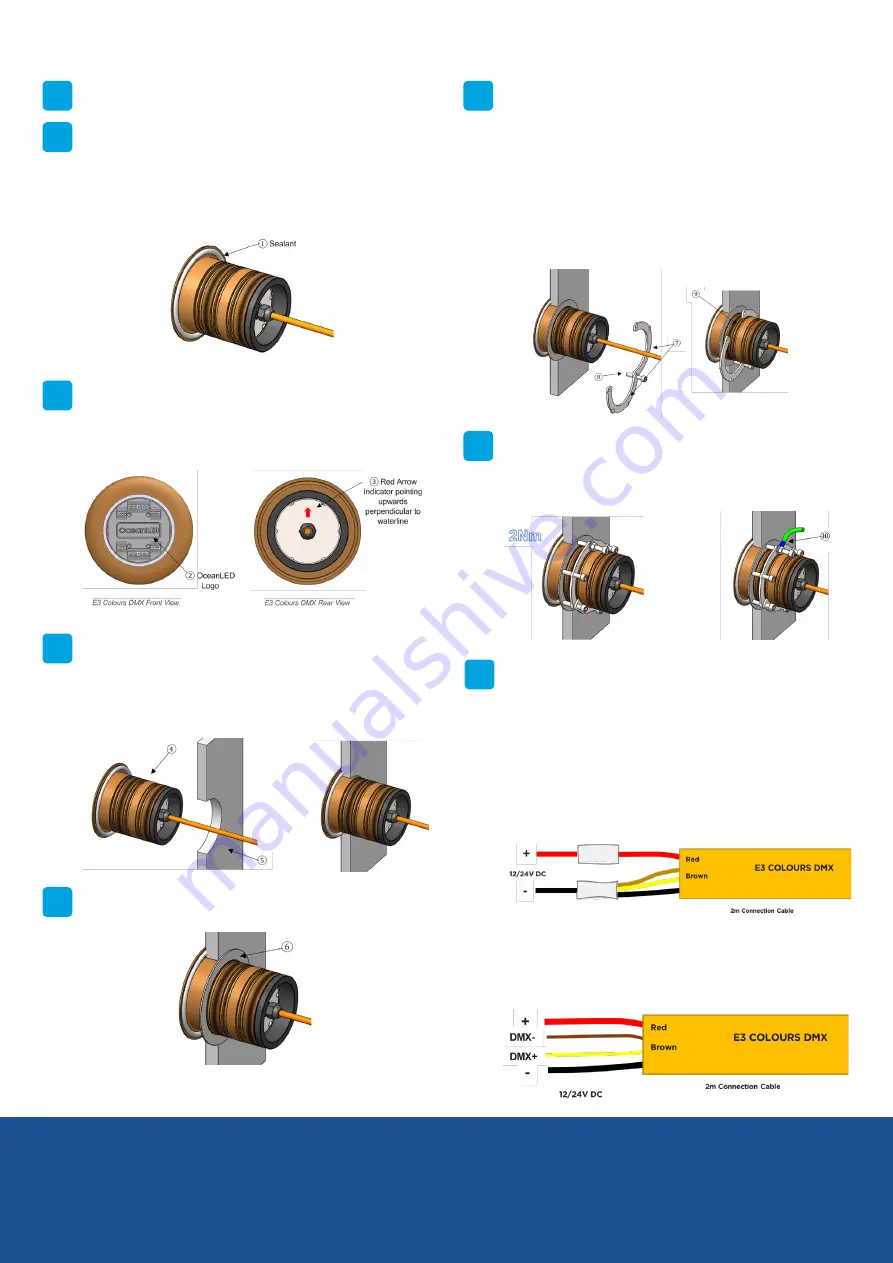

ELECTRICAL INSTALLATION:

Connecting light/s to your DC Power Source

OceanLED Explore models require a 12 or 24V DC

supply. This supply should be a minimum of 6A @12V

or 3A @ 24V DC per light.

E3 DMX Colours operated by switch

To use in DC switched mode; connect DC power +Ve

to the RED wire, and DC power -Ve to the BLACK,

BROWN & YELLOW wires

FOR FULL INSTALLATION INSTRUCTIONS, SEE THE

INSTALLATION MANUAL.

5.

Insert the stainless-steel compression washer (6)

over the mounting tube.

8.

E3 DMX Colours operated by DMX controller

Consult full installation manual for connection

method. This light requires a 2-way DMX Junction

Box for efficient distribution of power and the DMX

signal.

Feed the light cable through the hole in the hull and

insert the complete light unit (4) (mounting tube

as light cartridge) into the hull, pressing the

light hard into the hull (5) and twisting slightly to

spread the sealant behind the light to ensure good

adhesion.

6.

Take the two Clamping Clips (7) and align them to

form a circle, ensuring that you pair one threaded hole

with one non-threaded hole. Use one of the provided

screws (8) to secure the clips together, positioning

them approximately halfway down the length of the

screw. Insert the clips into the appropriate grooves

on the outside of the mounting tube (9). Make sure

the end of the screw is close to the washer. Use the

remaining screws to fix the two clips together. Use

the longer screw to connect the light to the vessel’s

cathodic protection system.

7.

Use a 5mm Allen key to tighten the locking screws,

ensuring that you apply thread lock at the point

where the threads make contact with the locking

ring. Attach the bonding cable (10) to the remaining

screw and secure