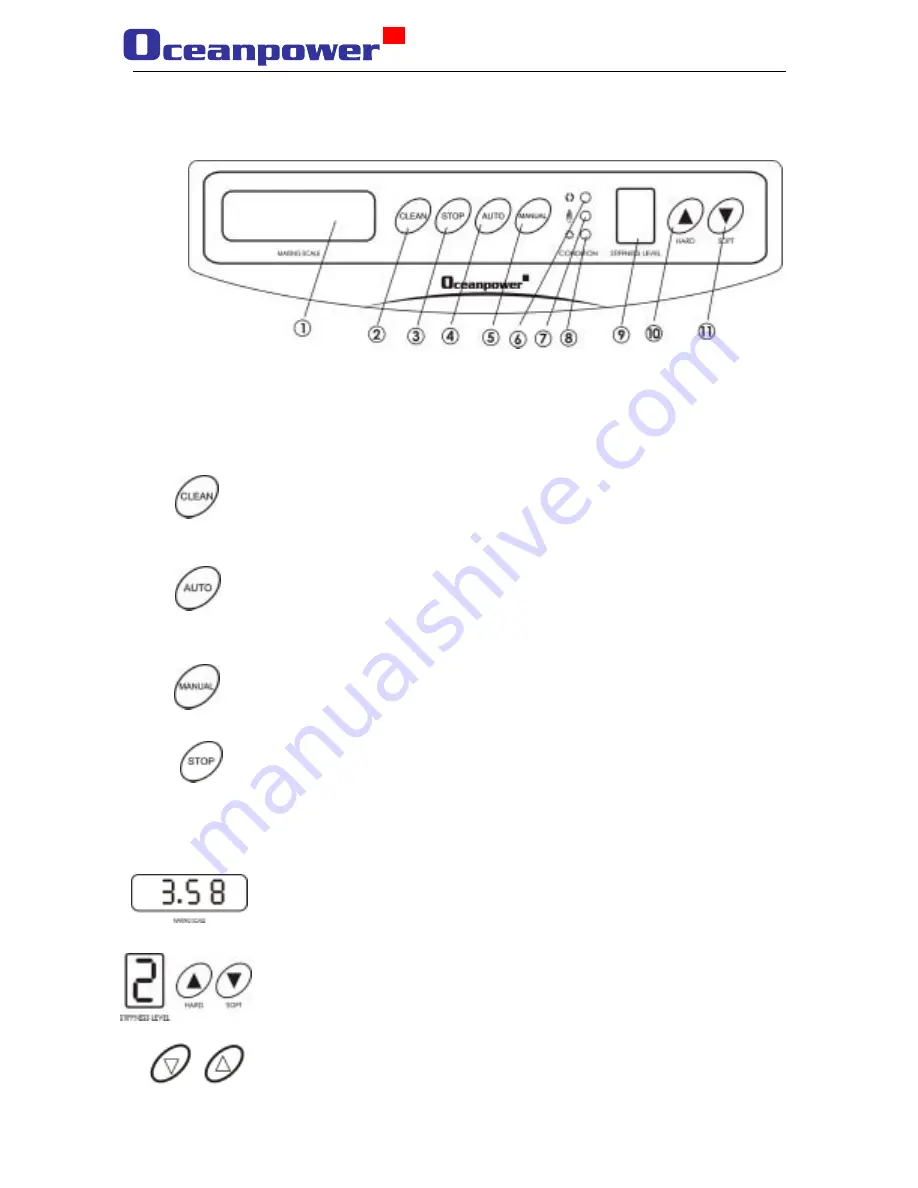

3.1 the machine controls

1. Display of the motors current 2.clean button 3.stop button 4. Button for automatic

operation 5. Button for manual operation 6. Indicator for cleaning condition (green

)

7. Indicator for refrigeration condition (blue

)

8. Indicator for STOP condition (red

)

9. Indicator of the hardness level 10. Button to increase the hardness 11 Button to

decrease the hardness

Cleaning

—

means auto-cleaning, the cylinder and the hoppers

need to be filled with water, the green light indicates the motor is

working.

Auto-operation

—

The machine will stop automatic, when

temperature and hardness meets the configured condition. If the

temperature rise, the cooling cycle will start automatically and the

blue light will indicate that normal operation occurs.

Manual-operation

—

Will start the cooling cycle manually, which

is suitable during high workloads, and the blue light will indicate

that normal operation occurs.

Stop

—

Will stop the machine. Remember that during cleaning or

repair of the machine the machine should be in STOP condition,

the red light indicates this.

Motors current

—

the screen indicates that the machine is working

and the number indicates the current in the motor. When the

configured number for the certain hardness level is reached, then

the machine will stop automatically; this number represent the

resistance in the cooling cylinder.

Hardness indication

—

it represents the set hardness value from 0-

7

,

the bigger the number, the harder products.

Hardness adjusting

—

adjust the hardness of the product.

16

Summary of Contents for OPF130

Page 5: ...Chapter 1 General information 5...

Page 11: ...Chapter 2 INSTALLATION 11...

Page 15: ...Chapter 3 OPERATING INSTRUKTION 15...

Page 19: ...Chapter 4 CLEANING AND SANITIZING 19...

Page 24: ...Chapter 5 TROUBLESHOOTING GUIDE 24...

Page 28: ...2 Follow the mixing rate according to the manufacturer 3 Try to always use fresh mix 28...