Document UT-MT-0428

Page 30 of 35

Edition 11/03/2014

Supersedes edition 04/30/2012

INSET RUNWAY EDGE LIGHT SLRE

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

4.5.1

Removing the filter

Clean out possible pieces of the old filter and all accumulated debris from the inside.

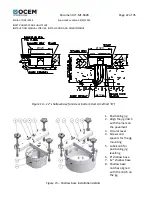

Remove the filter assembly (Figure 21 - n°2) unscrewing the relevant screws HSCH

M5x10 (Figure 21 - n°3).

4.5.2

Istalling the new filter

Place a new filter assembly (Figure 21 - n°2) and fix it to the dome using the relevant

screws HSCH M5x10 (Figure 21 - n°3). Inspect all components inside the fixture for

damages or signs of corrosion. Replace all necessary components.

Figure 21 - Filter Replacement

Close the light fixture following instructions of paragraph

“Closing the Fixture”,

“Leakage Test”

and

“Reinstalling the fixture”

.

4.6

RELAMPING

Remove the fixture from the base and open it following instructions of

“Removing

and Opening the Light Unit From the Base”.

Disconnect the male faston terminals of the lamp (Figure 22 - n°2) wires from the

insulating strip (Figure 22 - n°1) and slide the lamp out from its lamp-holder seat

(Figure 22 - n°3-4).

Connect the male faston terminals (Figure 22 - n°2) of the new lamp wires to the

insulating strip (Figure 22 - n°1) and slide the lamp into its lamp-holder seat (Figure

22 - n°3-4).

CAUTION: touching the quartz bulb with bare fingers may seriously shorten the lamp life. If the

quartz bulb has been touched, wipe it clean with a piece of fabric suitable for lens

cleaning, or similar, moistened with isopropyl alcohol

Reassembly the fixture following instructions of paragraph

“Closing the Fixture”,

“Leakage Test”

and

“Reinstalling the fixture”

.