BA_OLW I OTE3_SW5x_EN_20160815_V2

7 / 48

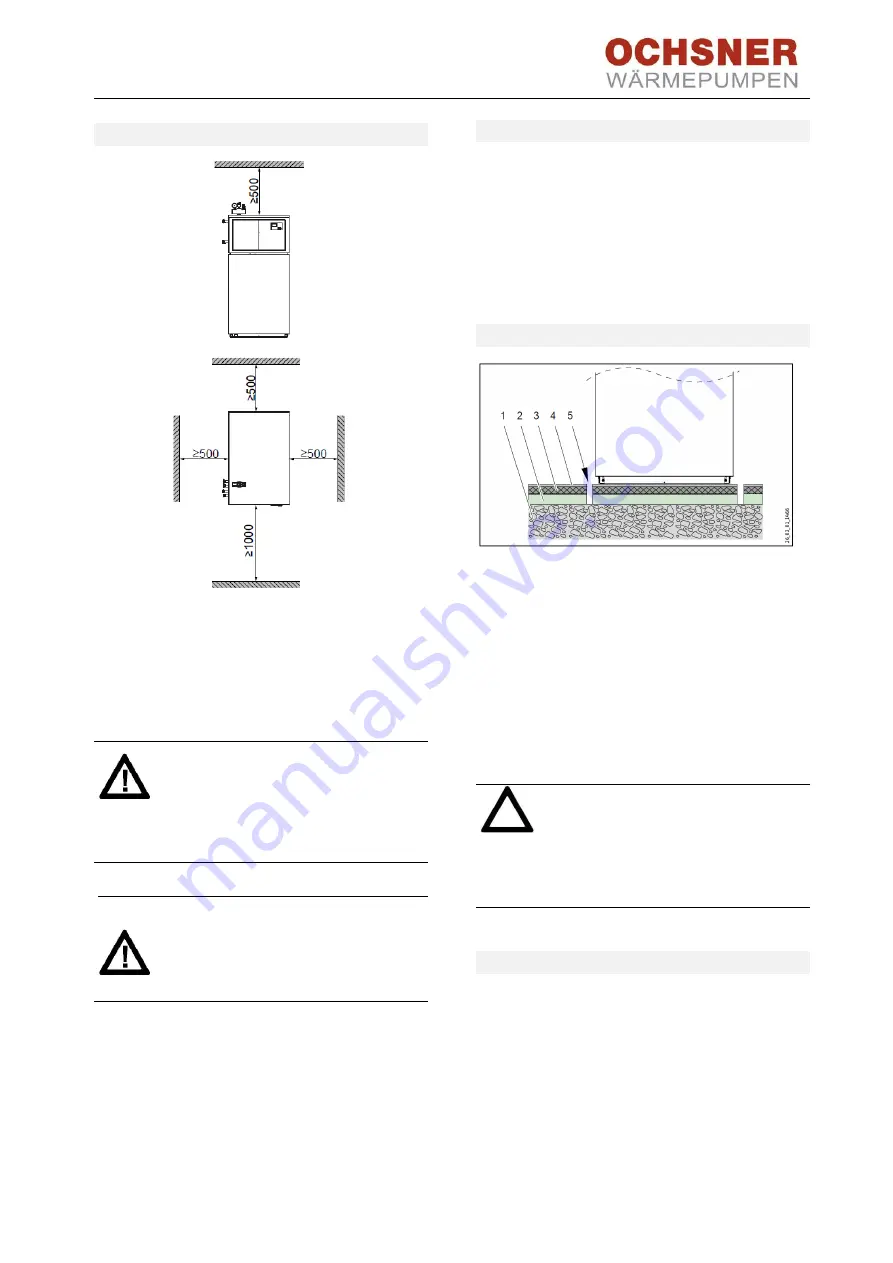

4.3 Minimum clearances

Dimensions in mm

Fig.4: Minimum clearances inside installation

►

Adhere to the minimum clearances in order to en-

sure a trouble-free operation and to allow service

work to be carried out.

Appliance and environmental damage

Make sure that the outside air can enter

and exit the appliance freely without hin-

drance

Should the air inlet and outlet be hindered, a thermal

short circuit could occur.

Appliance and environmental damage

The minimum air flow rate of the appliance

must be maintained at all times. Should the

air flow fall below the minimum, a trouble-

free operation cannot be guaranteed.

►

Ensure that the minimum air flow is maintained

.

See the information in the "Technical Data / Data

Table" section.

4.4 Foundation

General

► Make sure that the appliance is accessible from all

sides.

► Make sure that the foundation is horizontal, level,

firm and permanent.

► Ensure that the appliance frame fits uniformly on the

foundation Uneven ground can influence the noise

level of the heat pump.

4.5 Foundation

1 Concrete base

2 Footfall sound insulation

3 Floating floor screed

4 Floor coating

5 All-round cut-out

Fig.5: Base for inside installation

►

De-couple the installation area

Observe the following pointer:

-

Construct the pipework fixing and the wall

conduit in a sound-insulated fashion.

NOTE:

Dimension and positioning specifications for the air

inlet and outlet openings as well as the water and

electrical feed through can be found in the Section

"Technical Data / Dimensions and Connections".

4.6 Buffer tank

The use of a buffer tank is necessary in order to guar-

antee a trouble-free heat pump operation.

The buffer tank serves not only as a hydraulic decou-

pling of the water flow in the heat pump and heating

circuits, but also as a source of energy for defrosting.

Summary of Contents for OLWI 13

Page 2: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 2 48 ...

Page 25: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 25 48 14 2 Hydraulic diagram ...

Page 26: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 26 48 14 3 Electric circuit diagrams OTE ...

Page 27: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 27 48 ...

Page 28: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 28 48 ...

Page 29: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 29 48 14 4 Wiring overview ...

Page 37: ...BA_OLW A I OTE3_SW5x_DE_20160510_V2 37 48 15 Declaration of Conformity ...

Page 38: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 38 48 ...

Page 39: ...BA_OLW A I OTE3_SW5x_DE_20160510_V2 39 48 16 ERP Data ...

Page 40: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 40 48 ...