7

1-800-68-634

Octane Fitness Confidential

Issue

Possible Cause

What to Do

Machine produces “clunking”

noise when in use.

Loose links, pivots, or

rocker arms.

Check the rails, wheels, and wheel covers to ensure

that they are not rubbing against each other or

against the back shroud.

Open the top cover and using the moving handlebars

to slowly move the machine through the full range

of motion. This will help you determine if there is

anything hitting and/or clunking, such as the wire

harness rubbing against another part.

Check to make sure the 2-pivot/3-pivot joints on

both sides of the machine are tight (Figure 2.23).

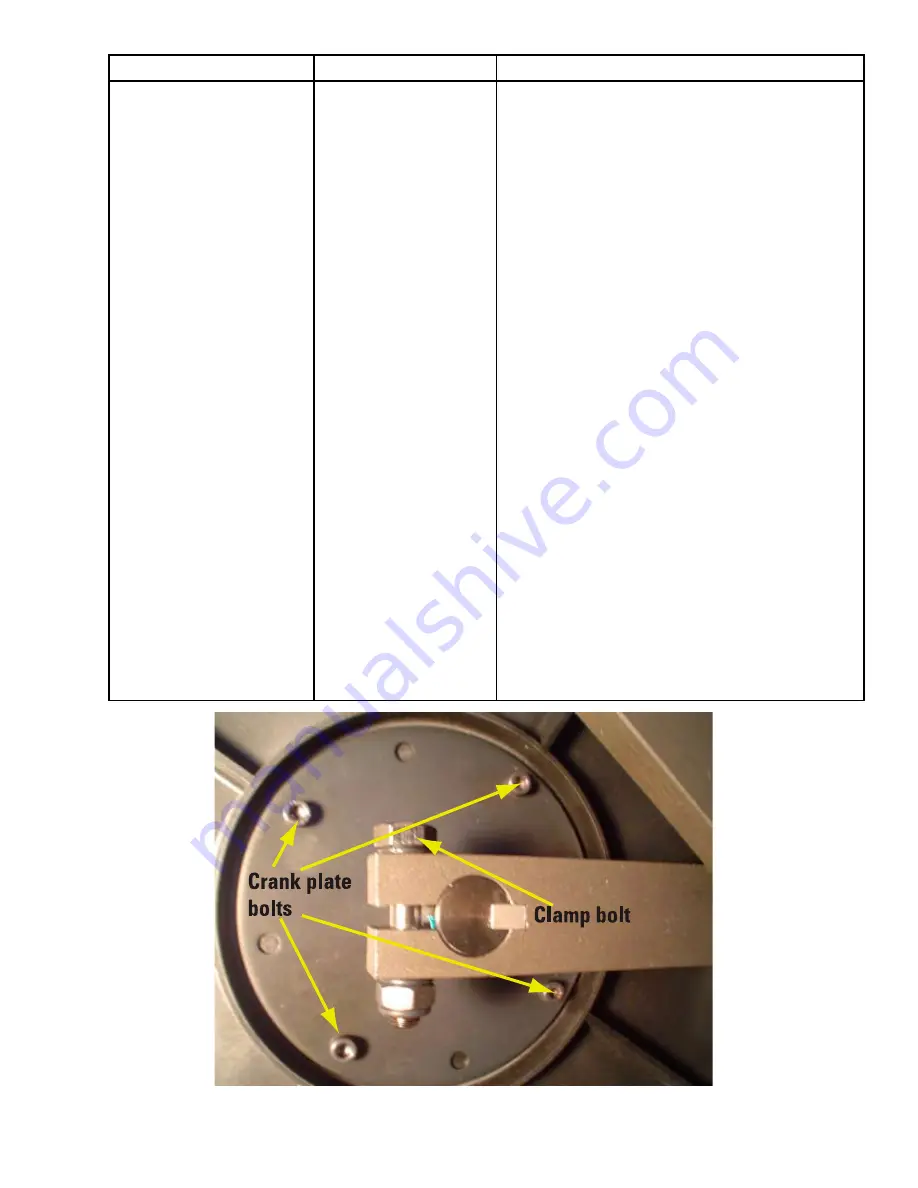

Check and tighten the four bolts attaching the crank

shaft plate to the large drive pulley (Figure 2.24).

Check and tighten the clamp bolt securing the crank

arm (Figure 2.24).

Try the machine at slow and fast pace, forward and

backward to see if the noise is still present.

Check the 2-pivot links and the 3-pivot links for

looseness and side-to-side motion. A slight side-to-

side motion is normal at the rocker arm and 2-pivot

link connection. No side-to-side motion should be

seen in the 3-pivot link assembly. Section III provides

directions for replacing links if necessary.

If the noise persists, detach the crank arm from

the middle 3-pivot bolt on both right and left sides.

Move the large wheel; if the noise persists you may

need to replace the pivot shaft and/or crank shaft

assembly. Refer to Section III for directions.

Figure 2.24