7

3

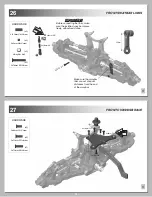

SPUR/DIFF GEARS

HARDWARE

7

7

4

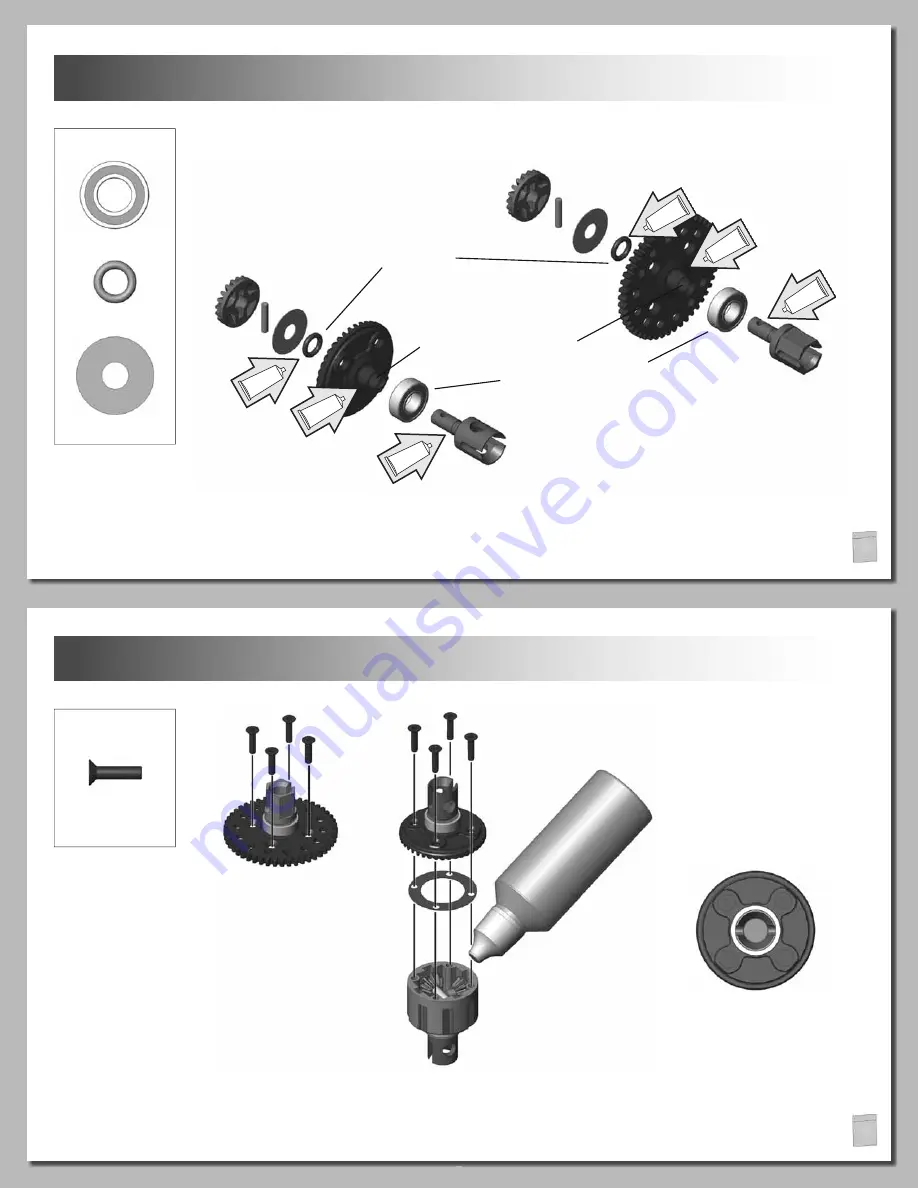

DIFF OIL

HARDWARE

Fill the diff until the planetary

gear shafts are completely

covered with diff oil. When

using heavy oils, you need to

allow the oil to settle and add

oil if necessary. Do not overfi ll!

(

Note:

See set-up sheet for

recommended diff oils.)

Finish tightening the diff

gear screws in order. This

will help make sure the gear

is mounted fl at on the diff

housing and the housing is

properly sealed.

1

2

3

4

Make sure the bearing is

fully seated on the gear.

Front/Rear x2

Center

Apply a small amount of the included

grease to the O-ring before installing.

This will help prevent damage to the

O-ring when installing the drive joint.

D

IF

F

O

IL

DIFF OIL

3x12mm FH

Screw

8x16mm Bearing

(x3)

Diff Outdrive O-Ring

(x3)

Sun Backing Washer

(x3)

(x12)

Grease

Grease

Grease

Grease

Grease

Grease

1

1

Build the front, rear and center diffs.

Apply grease in the groove

and a light fi lm of grease on

the shaft of all outdrives and

to the inside of the gears.