MAN# 650028

Series I

ODY-02-7 MINI TACHOMETER rev. C

•

250-18,000 rpm range with 10 rpm resolution. (100 rpm res. above 10,000)

•

Adjustable cylinder selection (1-15).

•

Adjustable warning point to flash the gauge readout.

•

High rpm recall.

Mounting:

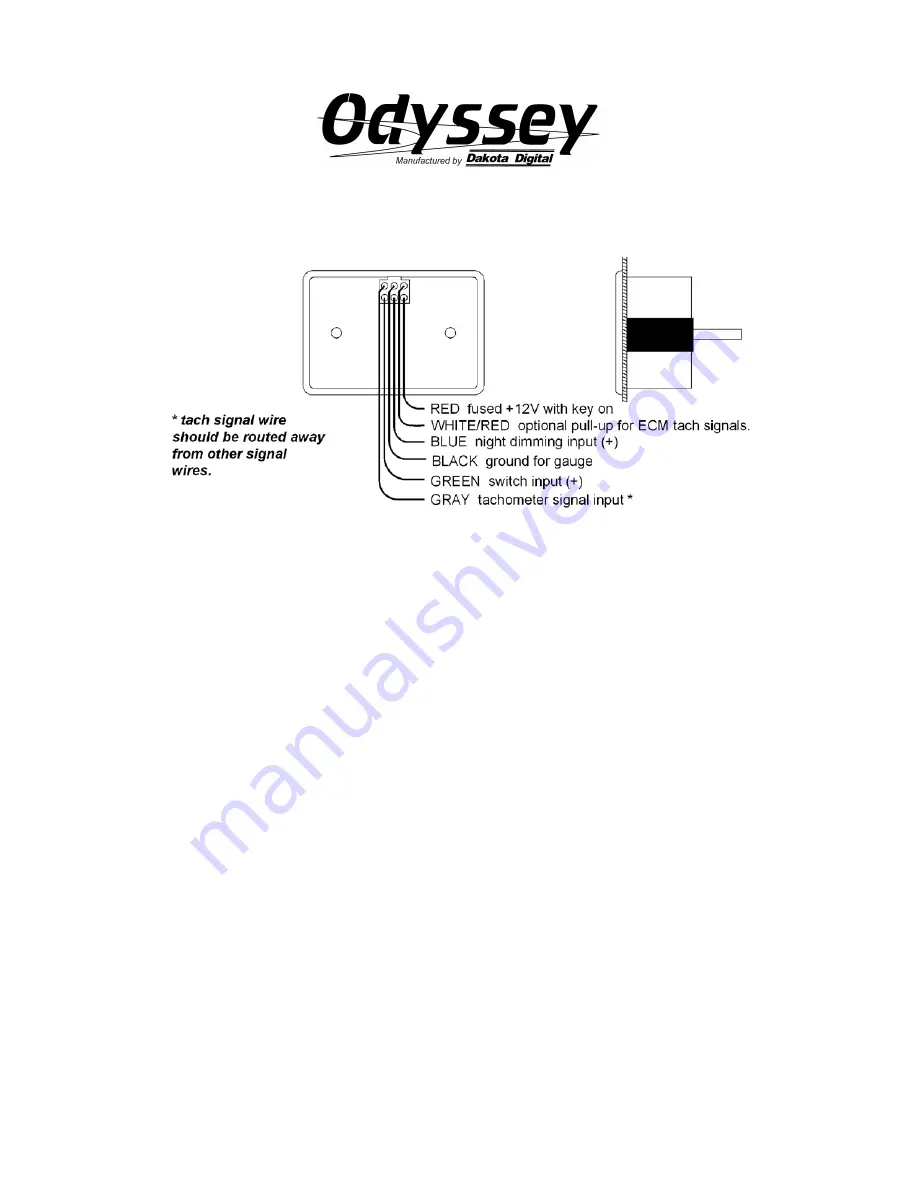

The Series I gauge requires a rectangular hole 2-9/16“ x 1-11/16“. . It should be inserted into the opening

from the front and the U-clamp will be installed from the back. Tighten the two nuts on the U-clamp so that the

gauge is secure. Gauge depth to the back of the case is 1”. Gauge depth including the mounting studs is 1-7/8”.

SETTING THE WARNING LIMITS, CYLINDER SETUP, AND UPDATE SPEED:

The setup is done using the function switch. The tachometer can be calibrated two different ways. The green

wire is used to enter and change the warning settings. You will need a switch connected with one side to the green

wire and the other side to 12 volts.

1. To enter the set mode, turn the key on with the switch pressed. The gauge will display “SEt”.

2. Release the swtich. The gauge will display “HI” and then change to the current hi rpm warning point. (2800

– 15,200)

3. Each time you momentarily press the switch the warning will increase 200rpm.

4. When the desired warning value is displayed, keep the switch held for about 2 seconds. The gauge will

display “CYL”.

5. Release the switch. The gauge will display the current cylinder setting. (1-15)

6. Each time you momentarily press the switch the number will increase by 1.

7. When the desired cylinder setting is displayed, keep the switch held for about 2 seconds. The gauge will

display “SPd”.

8. Release the switch. The gauge will display the current update speed. (slow “SLO” or fast “FSt”).

9. Each time you momentarily press the switch the display will change.

10. When the desired update speed is displayed, keep the switch held for about 2 seconds. The gauge will

display “--”.

11. Turn the key off.