4

Operating Instructions and Parts Manual

25822

3 PIECE HVLP

SPRAY GUN KIT

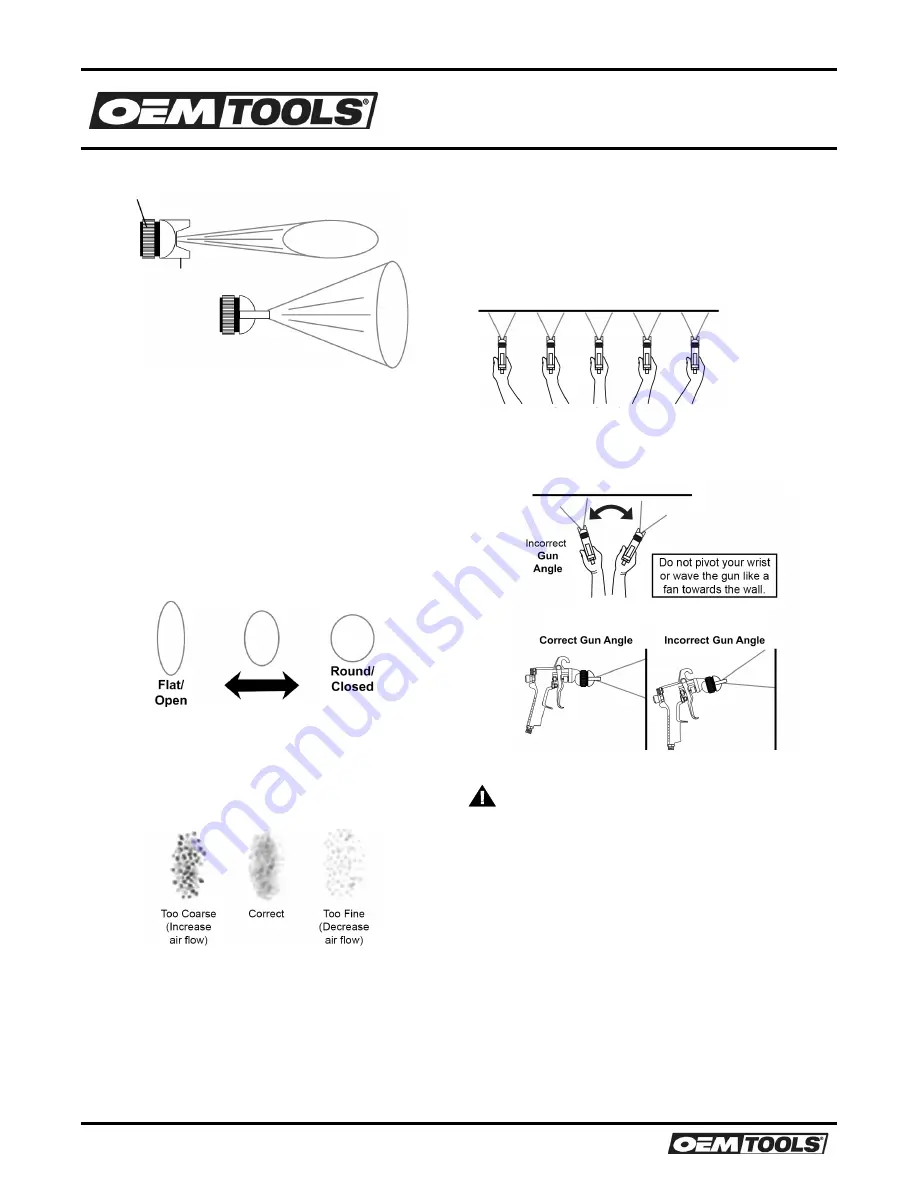

FAN DIRECTION

1. To change the direction of the fan from horizontal to vertical, loosen

the Lock Ring and turn the Nozzle 90°.

2. After the adjustment, tighten the Lock Ring by hand.

PATTERN ADJUSTMENT

1. Adjust the air supply pressure during operation with the Trigger fully

depressed and the Air Knob fully open. If reducing air pressure for

specific areas, use the Air Knob.

2. Use the Pattern Knob to adjust the spray pattern. Turn Pattern Knob

counterclockwise (all the way open) to flatten the spray pattern.

Turn it clockwise for a round spray pattern - see Figure E: Pattern

Adjustment.

FLUID ADJUSTMENT

1. Turn the Fluid Knob clockwise until it is fully closed.

2. After setting up a piece of test material, squeeze the Trigger in short

bursts while turning the Fluid Knob counterclockwise to set the

amount of fluid - see Figure F: Fluid Adjustment.

If spray is too fine:

Reduce the air pressure or allow more paint to come

out by opening the Fluid Knob.

If spray is too thick

(globs of paint)

:

Close the Fluid Knob slowly,

checking the pattern after each adjustment.

SPRAYING TECHNIQUE

IMPORTANT: Proper spraying technique is ESSENTIAL to achieve good

results.

1. First, prepare the HVLP Spray Gun according to the instructions

under HVLP Spray Gun Setup on page 3.

2. Keep the HVLP Spray Gun upright and at a right angle to the

workpiece- See Figures G and H.

3. Using two hands, one to steady the Cup and the other to operate the

HVLP Spray Gun, aim the Nozzle at the workpiece.

CAUTION

DO NOT STOP WHEN SPRAYING. Spraying materials will start to set

and dry as soon as they come in contact with the air. They will cause a

permanent clog if not cleared immediately. If discontinuing spraying for

more than half an hour, turn off the air supply, disconnect Cup from Gun

Body and thoroughly rinse Cup and Gun Body with fresh, clean water.

4. Pull Trigger slowly and move the HVLP Spray Gun in parallel strokes

to the workpiece. Keep the distance from the workpiece at about

6” to 9”, depending on the flow adjustment and the paint.

5. To avoid paint build up, start moving the HVLP Spray Gun before

squeezing the Trigger. When finished with the stroke, release the

Trigger while still moving the HVLP Spray Gun. Doing this will

produce a smoother finish. If the HVLP Spray Gun stops even briefly

while spraying the paint will build up and run down the workpiece.

Lock Ring

Nozzle

Horizontal Fan

Vertical Fan

Figure D: Fan Direction

Figure E: Pattern Adjustment

Figure F: Fluid Adjustment

Move your arm,

not just your wrist.

Point gun directly

towards the surface

and maintain an

even, steady distance

and speed.

Correct Gun Angle

Figure G: Spray Gun Angle - top view

Figure H: Spray Gun Angle - side view