6

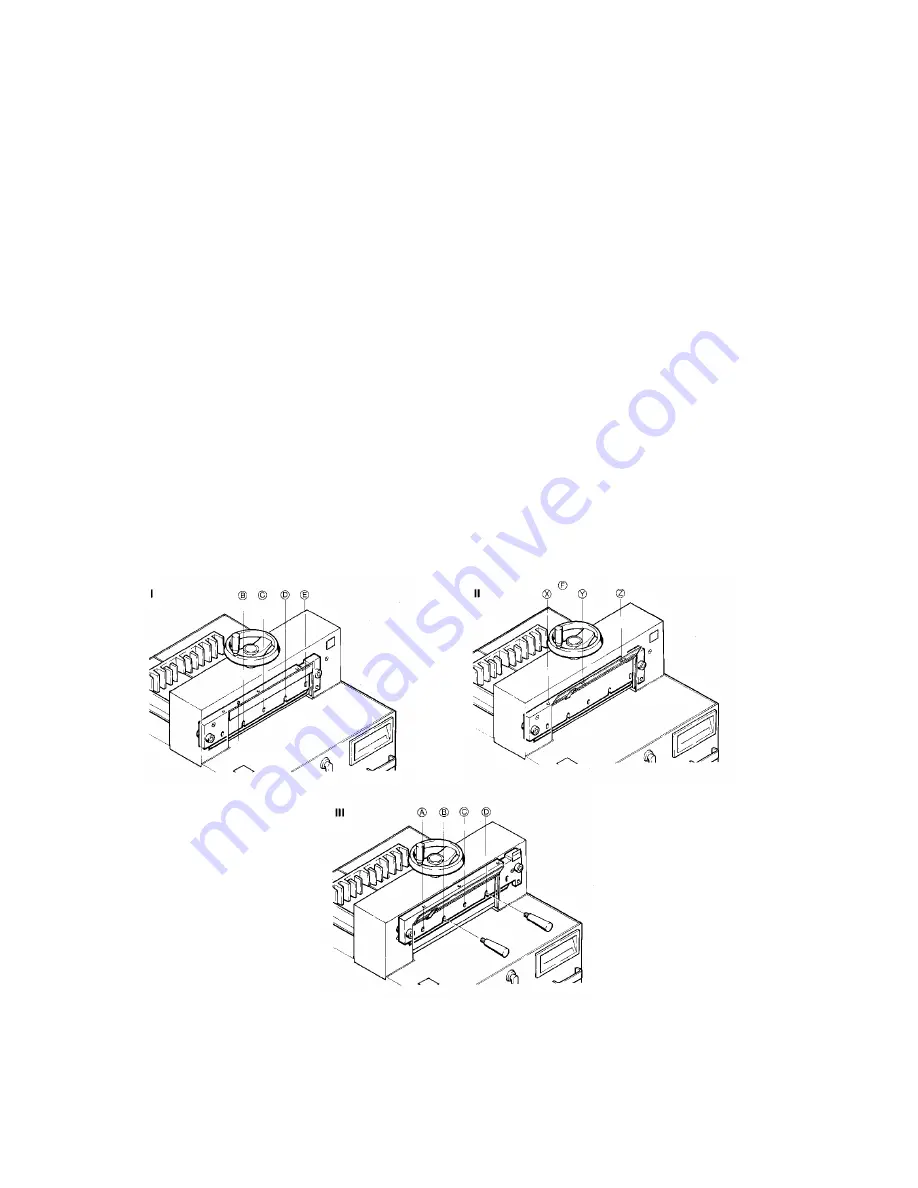

10. Screw in knife screws (A and C) – snuggly, don’t tighten.

11. Remove knife holders. Screw in knife screws (B and D) – snuggly, don’t tighten.

12. Spread one to three sheets of paper across the entire cutting length. Bring the knife (#17)

down. Release only one push button (#5) and turn main switch (#11) to position “0” (off)

again to stop the knife in its lowest position.

13. Screw in knife screw (E) – snuggly, don’t tighten.

14. The parallel adjustment of the knife is done via the knife adjustment screws.

Push knife down by screwing in the knife adjustment screws (X, Y, and Z) evenly, until the

paper is cut across its whole length.

15. Should the scope of the adjustment available by means of the knife adjustment screws be

insufficient, resort to the knife depth adjustment screw (#4). Turn it in steps of half a turn

clockwise (+). After each step a test cut has to be executed. If the paper is cut through only

on one side, proceed with parallel adjustment of knife as described under (#12 and #14).

IMPORTANT – Both the above methods (#14 and #15) of knife adjustment offer an

adjustment range of approximately 5 mm (1 / 4”).

16. Tighten knife screws (B, C, D and E) firmly while the knife is lowered on the cutting stick.

17. Turn main switch (#11) to position “|” (on). The knife returns to its home position.

18. Tighten knife screw (A) firmly. Screw in securing screw for knife adjustment flap (#20).

19. Make a test cut with a paper pile using the full cutting height. If necessary do a fin al

adjustment with the cutting depth adjustment screw (#4).

20. IMPORTANT – The clamp bar must be adjusted in a way that the cutting edge of the knife in

its home position is covered by the clamp bar.