7

Changing of cutting stick

Should the bottom sheet of a paper pile not be cut across its full length, the cutting stick (#2) must

be turned, rotated or exchanged.

IMPORTANT – If the knife has been lowered by means of the cutting depth adjustment screw

(#6) to compensate for a worn cutting stick, then this adjustment screw (#6) has to be turned back

to its highest setting before the cutting stick (#5) is turned, rotated or exchanged. Then re-adjust

screw (#6) again to obtain the optimal cutting depth. A knife that is set too low can inflict damage

not only to the cutting stick, but also to the knife and the knife drive system.

The cutting stick (#2) is inserted into the machine table and fixed by hooking it into a pin located

on the left between the knife guide plates.

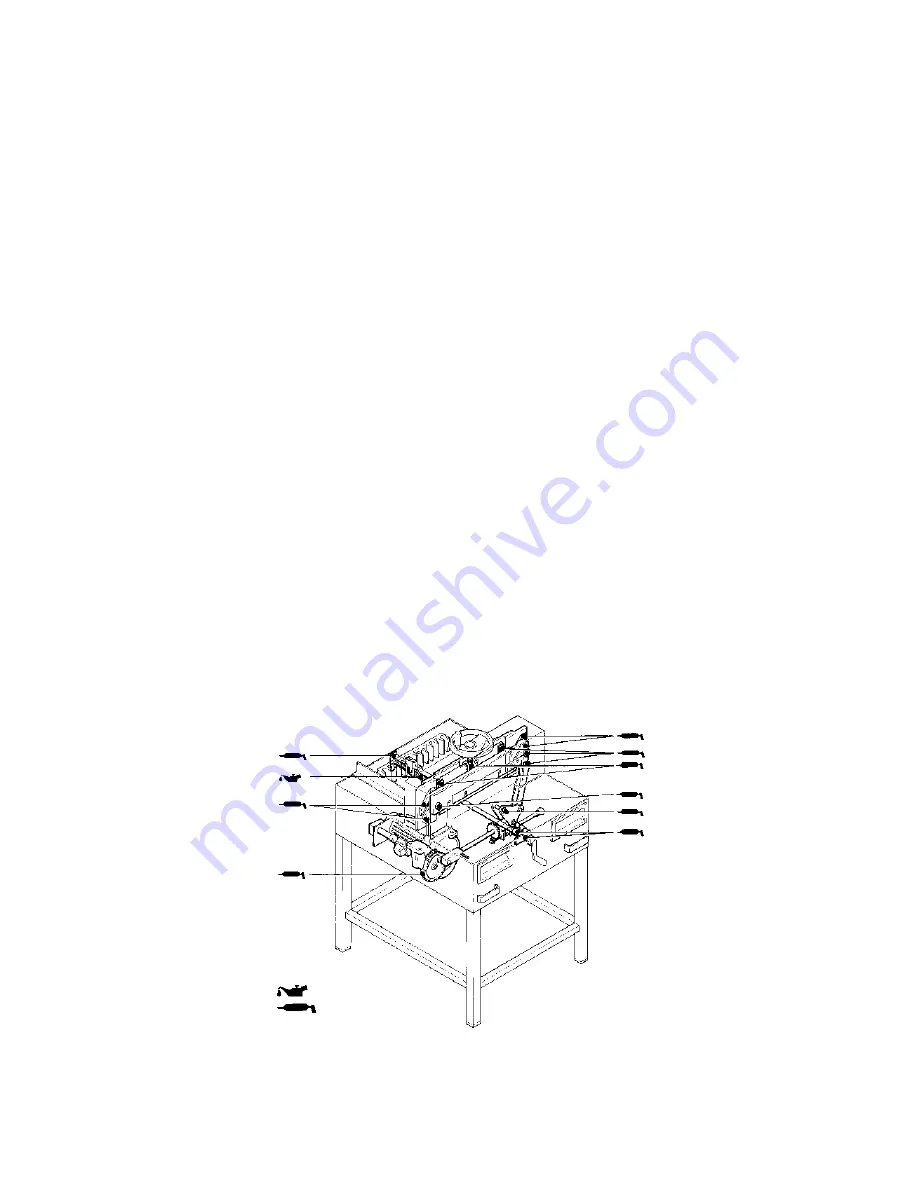

Lubrication

IMPORTANT – Before removing any machine covers for service or maintenance, always

disconnect machine from power supply.

From time to time all moving parts have to be oiled or greased. Before lubricating clean all parts

and ensure that they are free of paper dust and dirt. The following parts have to be lubricated:

1. The guide grooves and all other moving parts of the clamp assembly.

2. The knife carrier guide channels (left and right). They are located between the knife guide

plates.

3. All moving parts of the knife drive system. To reach these parts, the lower machine cover

(#9) and / or the front table (#13) must be removed.

4. The back gauge spindle, its housing points, and the back gauge guide mechanism.

The lubrication chart indicates all points to which “EP” grease or oil must be applied

A full lubrication of the machine is recommended at least once in every third knife change.