Officine Gullo

22

USER MANUAL

INSTRUCTIONS FOR USE

Attention!

The appliance must only be used under surveillance.

LIGHTING AND ADJUSTING THE BURNERS

On the front panel, above each knob, there is a symbol which indicates to which burner

the knob corresponds.

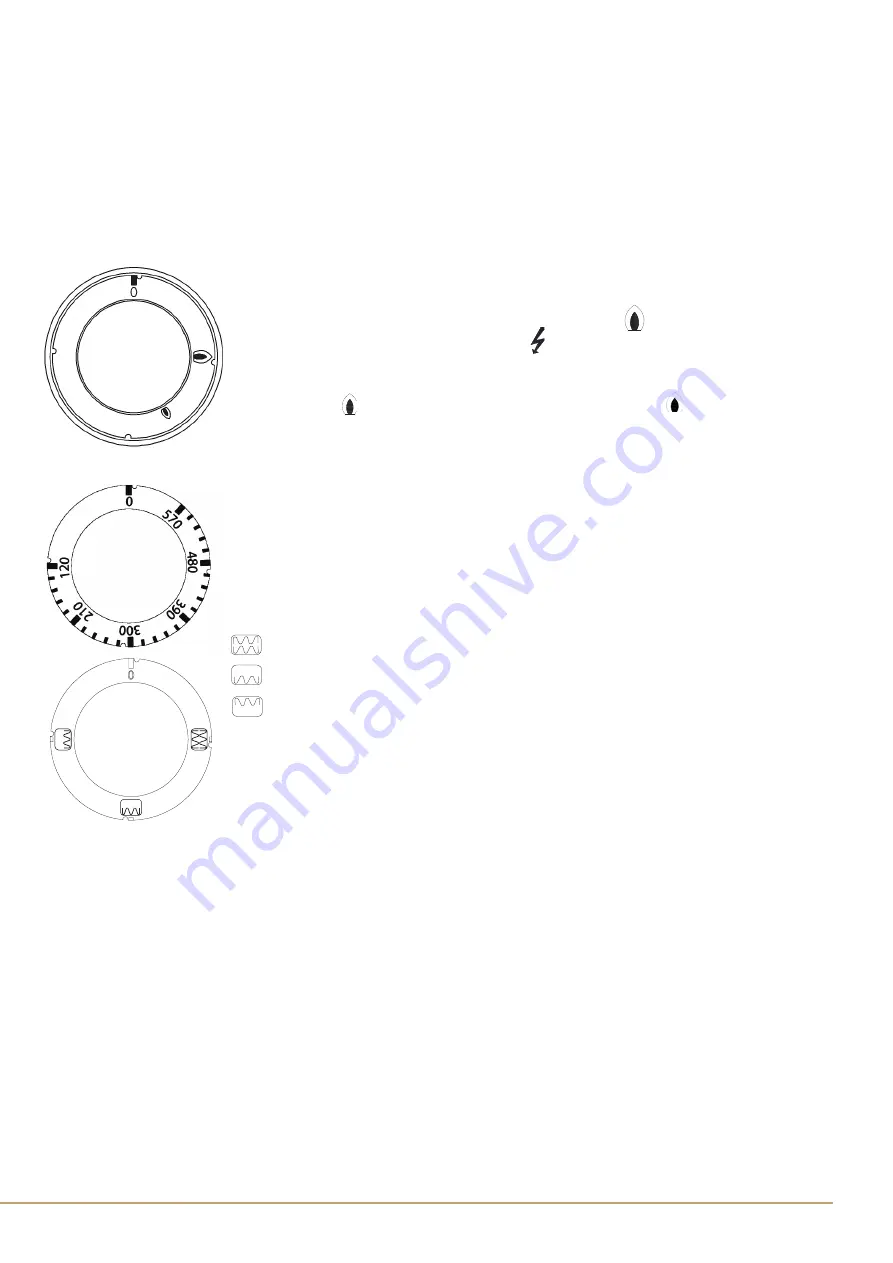

To light, turn the knob to the left from position “0” to the

symbol (see figure); keep it

pushed down and press the button with the

symbol until the gas lights.

The knob must be kept pushed down for a few seconds and then released. The flame may

go out, in which case it is necessary to repeat the procedure.

By turning to the

position, the burner is brought to minimum.

To switch off, move the knob back into position " 0".

TURNING ON AND ADJUSTING THE ELECTRIC OVEN

Before turning the oven on, make sure the oven racks are in the desired position.

Turn the control knob to the right and set the temperature wanted.

To turn the oven on, turn the selector knob (see figure) to the right or left into one of the

following positions.

Top + bottom heating element

Bottom heating element

Top heating element

Preheating the oven is essential for baking. It is recommended to pre-heat the oven to 30°F

warmer than the cooking set point fot at least 30 minutes. All cooking times are based on

a preheated oven unless otherwise stated in the recipe.

To turn the oven off, turn the knob to the left to position 0.

Caution:

when the oven is on, the door must be kept shut otherwise the knobs and protection sheet could get hot

and be damaged.

NEVER cover any slot, holes or passages in the oven bottom nor the ventilation grill on top of the range.

23

Officine Gullo

CARE AND CLEANING INSTRUCTIONS

General cleaning guidelines:

Wash surfaces gently with a soft damp cloth; use a neutral liquid soap with water for daily cleaning. Rinse completely

with water, dry any overspray. Never use an abrasive material such as a brush or scouring pad to clean surface. The

use of abrasive cleaners, cleansers or disinfectants will damage the surface finish and void the warranty.

We also recommends the general practice of spot testing all cleaning agents on an inconspicuous area prior to

applying.

We suggest a semi-annual wax routine using a high quality clear carnauba paste wax to extend the life of a living

finish. This will keep the finish close to its original form and minimize the appearance of use. The use of polishing

agents can damage finish and void the warranty.

Note that prolonged contact with certain items such as citrus fruit juice, salt, vinegar, mustard, pickles, mayonnaise,

anti-bacterial soap and wines on your surface for prolonged periods will also alter all surface finish.

NEVER USE:

•

Steel wool pads

•

Bleaches containing hypochlorite

•

Silver dip cleaners or polishes of any type.

Removing and cleaning burners

To clean the polished brass surface of your burnes you can use a metal polish of your choice, please note that the the

surface will start to oxidise again as soon as you start to use and that is a normal characteristic of polished brass. If

your burner surface is chrome plated (optional) please follow the instructions below for cleaning chrome plated brass

surfaces and note that you may also use metal polishes however please use it only occasionaly since metal polishes

are abrasive and it will take away some of the chrome plating with each use.

Cleaning burnished brass surfaces

The antiquing finish of the surface (Burnished Brass) is the result of natural oxidation that has been accelerated and

it is a “living finish”. Living Finishes have NO PROTECTIVE COATING so they can be scratched or scuffed if not

cared for properly.

The unique characteristic of these finishes is that they wear and age over time. Essentially, the finish replicates what

nature would do to the surface material naturally when exposed to the environment.

These products will generally tend to darken slightly on the areas that are infrequently touched and lighten or highlight

on the areas that are contacted on a consistent basis. Soaps, acidic fluids, and astringent cleaners can damage

the finish. Avoid using abrasive pads, sponges, or cloths to clean the product. Do not allow water spots to dry on.

Cleaning chromed brass surfaces

This finish is achieved by chrome plating solid brass and it is a “living finish”.

Living Finishes have NO PROTECTIVE COATING so they can be scratched or scuffed if not cared for properly.

This durable finish will not change if the general cleaning guidelines are followed.

Please follow the general cleaning guidelines to keep this finish close to its original form and minimize the appearance

of use.

Cleaning nickeled brass surfaces

This finish is achieved by nickel plating solid brass and it is a “living finish”.

Living Finishes have NO PROTECTIVE COATING so they can be scratched or scuffed if not cared for properly.

Oxidation that may appear over time on the nickel plated brass surfaces is a normal characteristic of this living

finish. Please follow the general cleaning guidelines to keep this finish close to its original hue and minimize the

appearance of use.

Summary of Contents for GES8MPU

Page 2: ...Officine Gullo 2...

Page 25: ...25 Officine Gullo...

Page 26: ...Officine Gullo 26...

Page 27: ...27 Officine Gullo...