Officine Gullo

8

DECLARATION OF COMPLIANCE

This appliance is manufactured by OFFICINE GULLO S.r.l

Headquarters and factory

Via Della Torricella 29, Antella, Bagno a Ripoli

50012 Florence - Italy

Tel. +39 055 65 60 3324

+39 055 62 18 07

officinegullo.com | info@officinegullo.com

The manufacturer declares that the appliances are compliant with the prescriptions of the EEC norm 2009/142

for the gas part and with norm 2006/95/CE, 2004/108/CE for the electric part. The installation must be done

observing the norms in force particularly concerning room ventilation and discharging gas emissions.

N.B.: The manufacturer declines any responsibility for direct or indirect damage caused by improper or incorrect

installation, alterations, maintenance or use of the appliance, as in all the other cases considered in the items of our

sales conditions.

GAS TECHNICAL DATA TABLE

MODEL

Dimensions

cm

Burner

7 kW

Burner

12 kW

POWER

Tot. kW

Gas coupling

ISO 7-1

TPS4P

40 x 70 x 29h

1

-

7

R 1/2”

TPS8P

80 x 70 x 29h

-

1

12

R 1/2”

ELECTRIC TECHNICAL DATA TABLE

MODEL

Dimensions

cm

Power supply

Max.

Absorption

(A)

Max. Power

(KW)

Power supply

cable (Silicon)

TPS4P

40 x 70 x 29h

230V~ 50/60 Hz

0,04

0,01

5x1

TPS8P

80 x 70 x 29h

230V~ 50/60 Hz

0,04

0,01

5x1

9

Officine Gullo

INSTALLATION

•

The operations for installing, conversions for use with other types of gas and starting up must be done only

by qualified personnel whose qualifications comply with the norms in force.

•

Gas installations, the electrical connections and the rooms in which the appliances are installed must comply

with the norms in force in the Country in which the installation is carried out; above all, the appliance must

be installed in a well ventilated room, preferably under an extractor hood, so as to ensure the complete

extraction of gas emissions which are formed during combustion. The air necessary for combustion is

2m3/h per kW of power installed.

Attention:

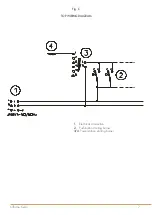

In accordance with international rules, when connecting the appliance, an automatic device enabling the

disconnection of all contacts from the mains, must be installed above it; this device must have a contacts opening

of at least 3 mm.

CHECKING FOR ADEQUATE VENTILATION

Make sure that the air intake into the room where the appliance is installed is sufficient for an adequate change of air, as

specified by regulations in effect.

The appliances installed in buildings open to the public must satisfy the following requirements.

Installation rules

The installation and maintenance of the appliance must be done according to the correct procedures and regulation

texts in use, particularly:

• safety standards for the prevention of fire and panic.

Connection and installation of appliance, ventilation and exhaust removal systems, shall be done according to the

Manufacturer’s instructions and by qualified technicians and according to the regulations in effect. The electric wiring shall

conform to the regulations in effect.

All fire prevention codes shall be observed.

a) General indications

(Rules valid for GB only)

- For all appliances:

Gas safety Regulations, 1984; Health and safety at Work Act, 1974 Codes of Practice, BS 8173, 1982, The Building

Regulations 1985; The Building Standards Regulations, 1981, the IEE Regulations and the by-laws of the local Water

Undertaking.

The local gas Region or LPG supplier and the local authority and the relevant recommendation of the British Standards

(latest editions) concerned.

The installation, transformation and repair of appliances for professional kitchens as well as removal due to malfunction,

and the supply of gas, may be made only by means of a maintenance contract stipulated with an authorized sales office

and in observance of technical regulations.

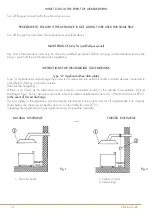

The appliance can be installed by itself or in a series side by side with appliances produced by us.

There must be a minimum distance of at least 10 cm between the appliance and the sides of the nearby cabinets made

of inflammable material.

Take suitable measures to guarantee thermal insulation of the inflammable sides, such as, for example, the installation of

protection against radiation.

The appliances must be installed in a suitable manner, observing the safety standards.

The small feet are adjustable to level the appliance.