OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ofite.com

31

Maintenance

1. HTHP cell assemblies should periodically be checked

for:

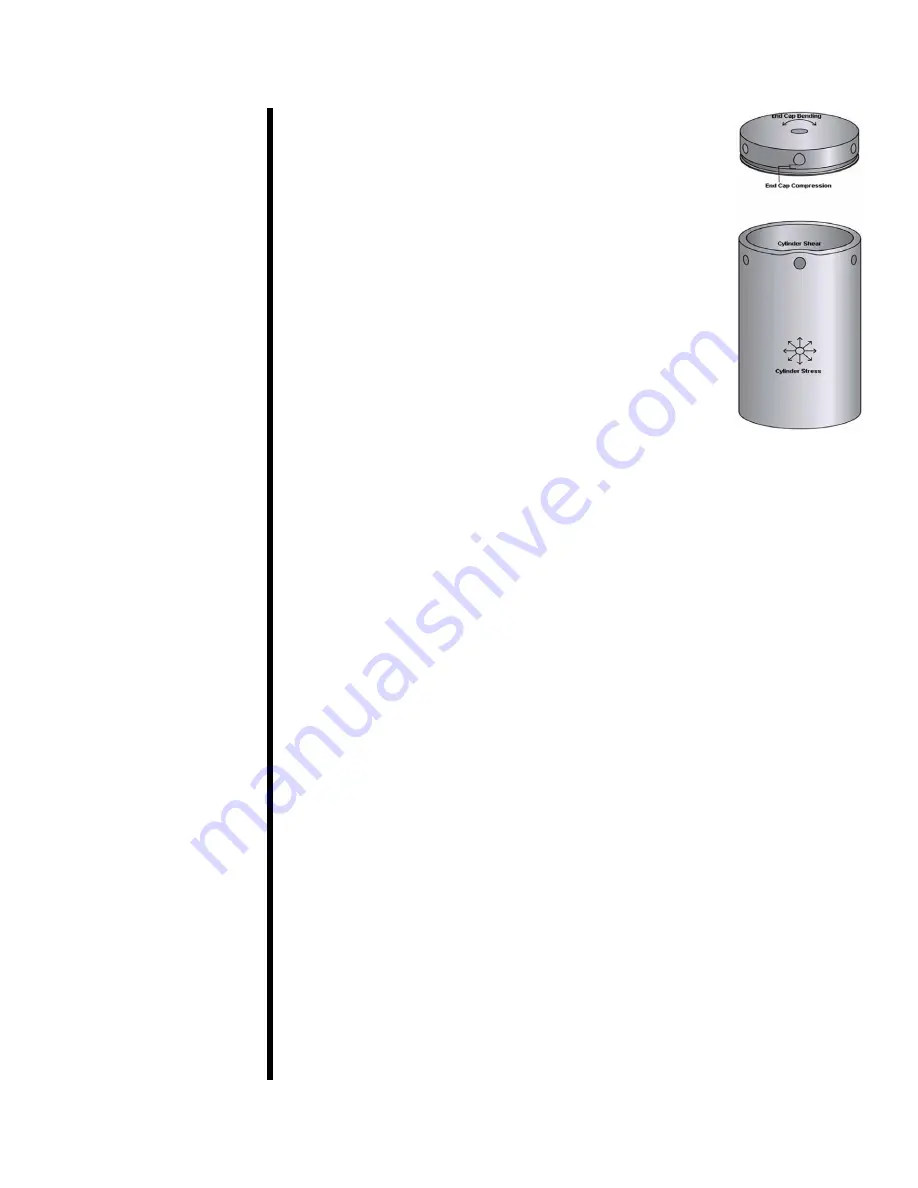

a. Cell Corrosion – Stress cracking or pitting

b. Cylinder Shear – Raised areas above the cell set

screw holes

c. Elongated set screw holes in the cell bodies

d. End Cap Compression – Elongated set screw de

-

pressions on cell caps

e. Set screws which are no longer tapered on the in

-

side

f. Elastomers – Check for flat spotting and melting

g. Valve stems should be sharply pointed and not dull on outlet side.

2. Always thoroughly clean up after each tests.

a. Replace all elastomers if previous test was in excess of 300°F

(149°C).

b. Clean out and blow dry if possible, the back pressure receiver.

c. Cell body must be completely cleaned with special attention to the o-

ring groove.

3. Periodically check for leaks.

a. Cell Assembly – Immerse sealed pressurized cell assembly in a sink

filled with water – look for bubbles.

b. Top Pressure Assembly – Immerse regulator, valves, and sealed cell

assembly in a sink full of water and look for bubbles. Hold assembly

by the gauge and do not let the gauge get wet.

c. Back Pressure Receiver – Similar to “B”. Hold assembly by the gauge

and do not allow it to get wet.