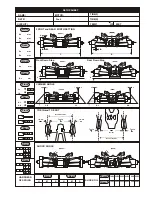

39413

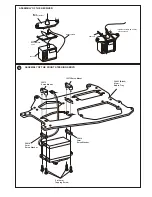

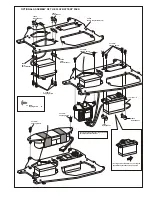

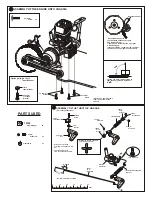

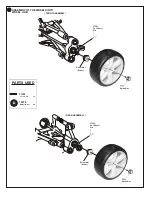

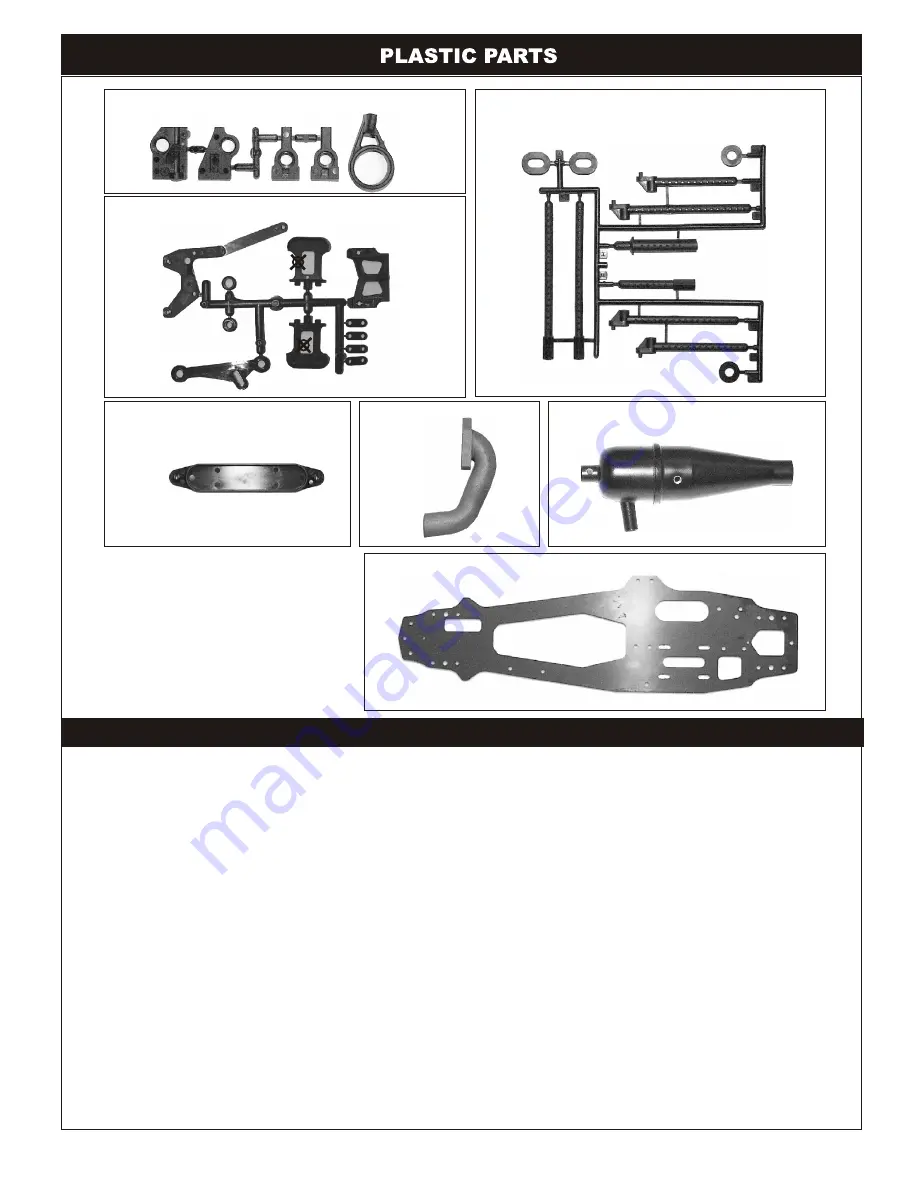

MAIN SHAFT BLOCK PLASTIC PARTS

39414

REAR BLOCK COVER PLASTIC PARTS

37968

BODY POST

39416

BATTERY HOLDER, FLAT PACK OPTION

37949

MANIFOLD

31890 PIPE

39420

CHASSIS

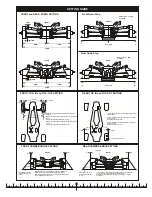

R/C TIPS

R/C cars are fun to drive, but be aware that driving them in the wrong places can cause serious damage.

Never drive near real cars, animals, or people that are unaware the R/C car is being driven.

When learning to drive, go to an area that has no obstacles that can damage your car if you have a crash.

Stay away from curbs, parked cars, poles, etc. Always wear shoes when driving.

SAFETY PRECAUTIONS

Follow the outlined rules for safe radio control

operation.

1. Make sure that no one else is using the same

frequency in your running area. Using the same

frequency at the same time can cause serious

accidents, whether it's driving , flying, or sailing.

2. Avoid running in standing water and rain. If

R/C unit, motor, or battery get wet, clean and dry

thoroughly in a dry shaded area.

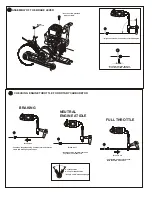

R/C OPERATING PROCEDURES

1. Make sure the transmitter controls and trims are

in neutral.

2. Switch on transmitter.

3. Switch on receiver

Inspect operation using transmitter before running.

Revers sequence to shut down after running, and

make sure to disconnect or remove batteries.

INSPECTION BEFORE OPERATION

1. Make sure that screws and nuts are tight enough.

2. Make sure that batteries for transmitter are new,

and Ni-Cad running batteries have been sufficiently

charged.

If batteries are not new or fully charged, the model

may run out of order.

3. Adjust steering servo and trim so that the model

runs straight with transmitter in neutral.

4. Double check speed controller for neutral position.

5. Double check for wiring breaks and short circuits.

6. Check motor function. Unusual noise or excessive

heat build-up in a short period may indicate a

damaged motor.

7. Apply grease to suspension, gears, ballbearings, etc.

MAINTENANCE AFTER RUNNING

After operating the model, perform the following to

maintenance for best performance.

1. After running model, switch off transmitter and re-

move batteries from model and R/C unit.

2. Completely remove sand, mud, dirt, etc.

3. Apply grease to suspension, gears, ballbearings.

4. Do not use water or solvents to clean your model.

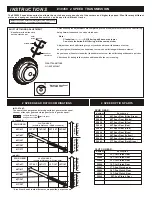

INSTRUCTIONS

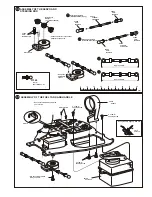

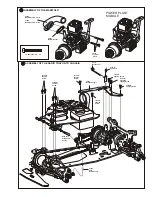

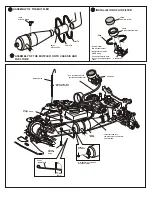

#39450 2 SPEED TRANSMISSION

The #39450 2 speed transmission allows the car to have more punch out of the corners and higher top speed. We offer many different

pinion and spur gear combinations which can be used for different tracks.

*Notice the direction of

the clutch cam.

* Use a 2mm allen wrench to

set the clutch cam.

* Adjust the engine before adjusting the clutch shift timing.

Adjust the engine as per engine instruction manual.

2mm

Allen Wrench

Clockwise

Counter

clockwise

1. Once the engine adjustments are completed, proceed to adjustment of the clutch shift timing.

Using 2mm allen wrench to set the clutch cam.

Note:

Clockwise-------------Shift timing will become slower.

Counter clockwise-Shift timing will become quicker.

2. Adjust the clutch shift timing for your track conditions with 4x4mm set screw.

As you tighten (Clockwise) the 4x4mm set screw , the shift timing will become slower.

As you loosen (Counter clockwise ) the 4x4mm set screw, the shift timing will become quicker.

3. Set the shift timing to the track conditions while the car is running.

SHIFT UP TIMING ADJUSTMENT

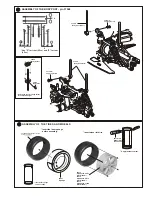

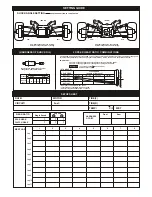

2 SPEED GEAR RATIO COMBINATIONS

2 SPEED OPTION PARTS

IMPORTANT:

The sum of the spur gear and clutch gear for1st gear must be equal

the sum of the spur gear and clutch gear for 2nd gear

.

be equal

Example:

1st gear 45+13=58

2nd gear 41+17=58

Must be equal

* Also 2 tooth and 5 tooth differences arepossilbe, but not shown..

SPUR GEAR

CLUTCH GEAR

45T/41T

13T/17T

44T/40T

43T/39T

42T/38T

41T/37T

(4 tooth difference - OFNA standard)

14T/18T

15T/19T

16T/20T

S

h

o

rt

T

ra

c

k

T

o

rq

u

e

T

o

p

S

p

e

e

d

L

o

n

g

T

ra

c

k

SPUR GEAR

CLUTCH GEAR

45T/43T

13T/16T

44T/41T

43T/40T

42T/39T

41T/38T

(3 tooth difference - HPI standard)

14T/17T

15T/18T

16T/19T

S

h

o

rt

T

ra

c

k

T

o

rq

u

e

T

o

p

S

p

e

e

d

L

o

n

g

T

ra

c

k

( STANDARD)

¤

j

¾

¦

(MODIFY)

35952 45T Spur Gear (Olive Green)

35965 44T Spur Gear (White)

35934 43T Spur Gear (Blue)

35942 42T Spur Gear (Red)

35953 41T Spur Gear (Pink)

35964 40T Spur Gear (Grey)

35935 39T Spur Gear (Yellow)

35963 38T Spur Gear (Orange)

35943 37T Spur Gear (Dark Green)

SPUR GEAR:

Number

Description

CLUTCH GEAR:

Number

35948 13T-1st Clutch Gear

35949 14T-1st Clutch Gear

35940 15T-1st Clutch Gear

35944 16T-1st Clutch Gear

35947 17T-2nd Clutch gear

35950 18T-2nd Clutch Gear

35941 19T-2nd Clutch Gear

35945 20T-2nd Clutch Gear

Description

Use thread lock

on set screw!