8

7.

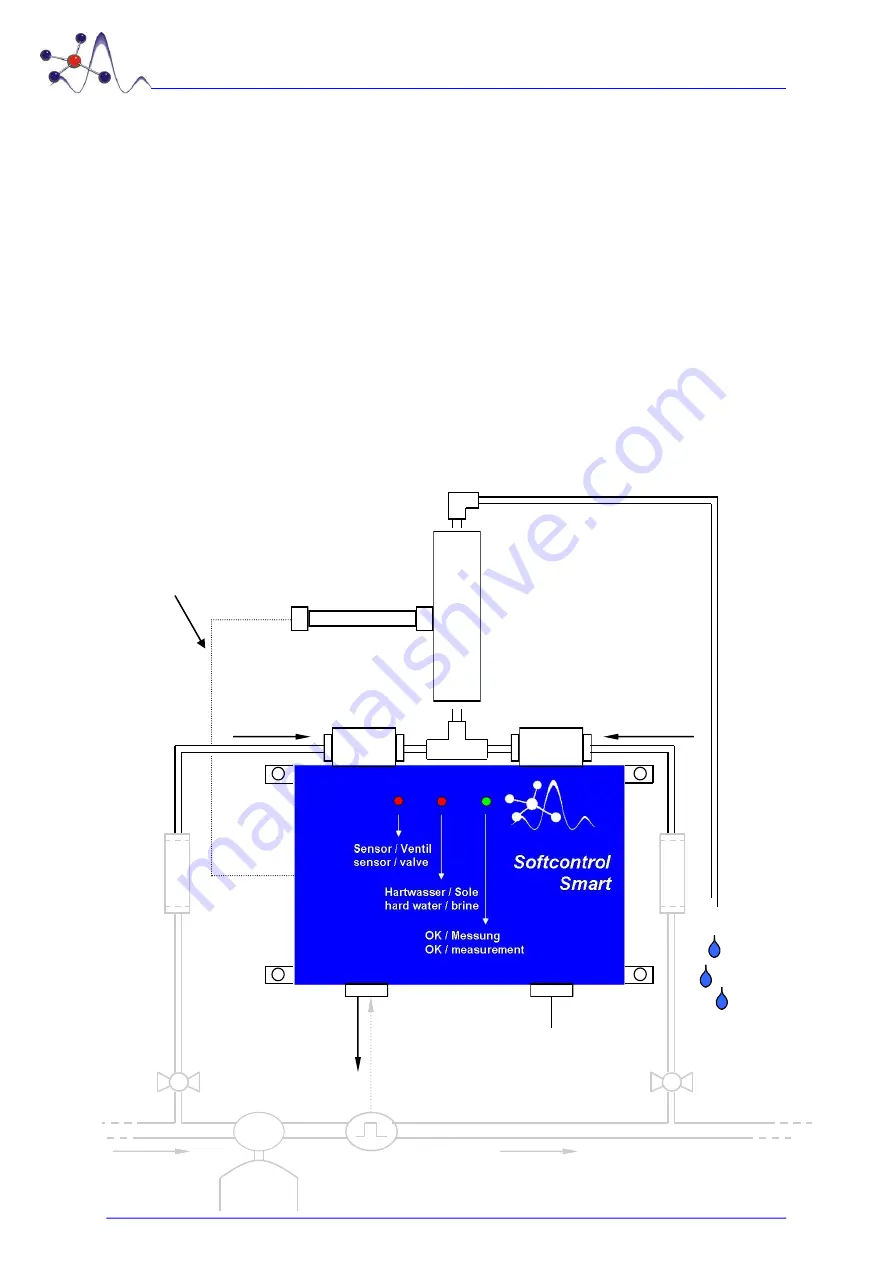

General overview of functions

Softcontrol Smart is an online water hardness measuring system for the continuous monitoring of soft

water on a connected water softening system based on cation exchangers for increased hardness con-

centrations.

For this purpose, the device in the bypass takes minimal amounts of raw or soft water from the process

in a time-controlled or flow-controlled manner, evaluates the residual water hardness and issues an

alarm if hardness breakthroughs are detected. At a fixed hardness limit of 10% based on the input wa-

ter hardness, the device triggers an alarm. The determination of the water hardness is possible from

0.18 mmol/l raw water hardness. The measurements are carried out cyclically every 15 minutes in a

flow measuring chamber, in which a selective sensor for calcium and magnesium ions is inserted pres-

sure-proof. Alternatively, the measuring cycle can be controlled by pulses from a connected water

meter.

The process water samples are exchanged by automatically opening or closing the upstream shut-off

valves and then discarded without pressure. If hardness breakthroughs are recognized or a service case

for the measuring system is required, an alarm is signaled. The measurement functions and their re-

sults are displayed with colored LEDs. The measuring system calibrates itself through automatic, cy-

clical switching from soft water to raw water.

raw water

drain

(pressure free)

raw water

optional

external

signal-output

optional

connection

water meter

valve

raw water

sensor

m

ea

s

ure

me

n

t

c

ha

m

be

r

power supply

240V / 50 Hz

V

softener

sensor cable

soft water

fi

lt

er

fi

lt

er

valve

soft water

5

soft water

Summary of Contents for Softcontrol Smart

Page 1: ...Softcontrol Smart Instruction Manual Version 2 3...

Page 2: ......

Page 4: ...4...

Page 22: ......