13

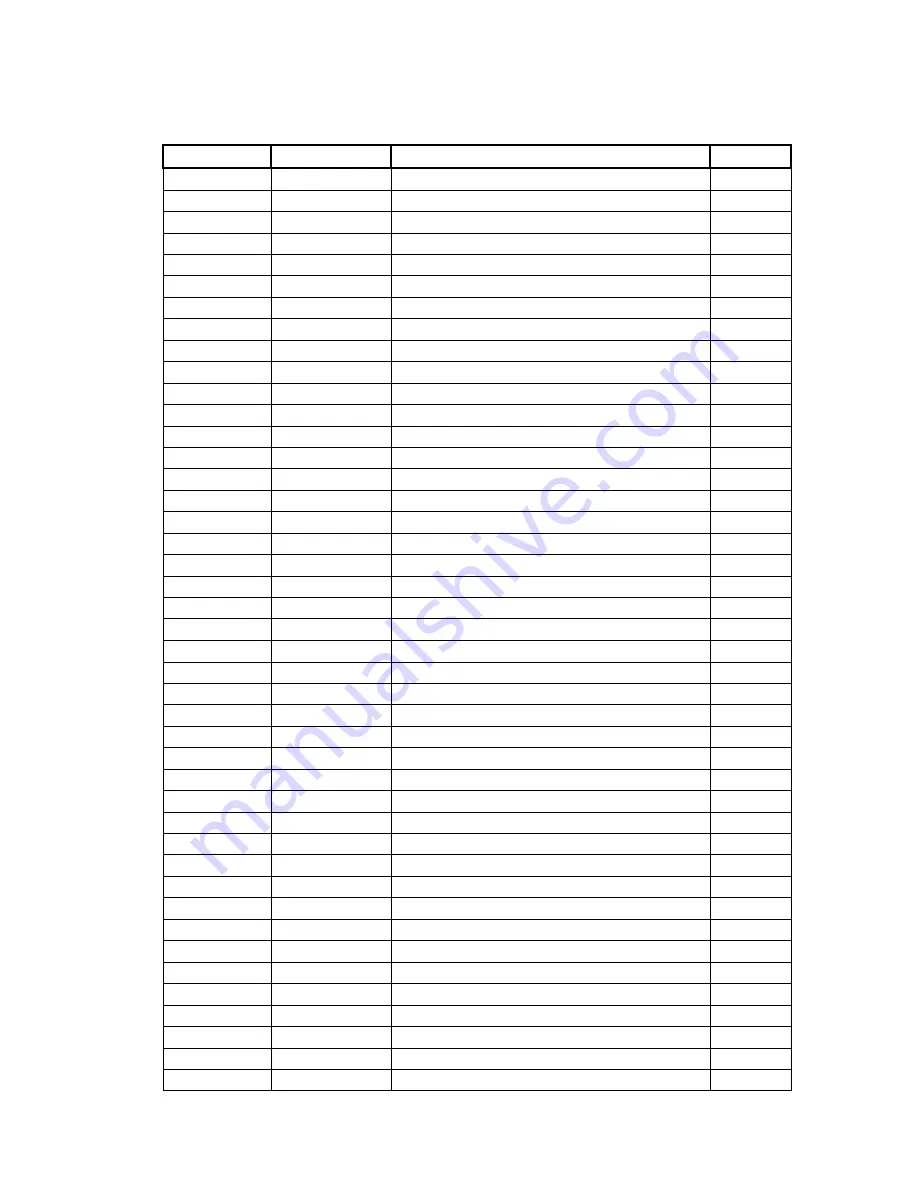

BCH610 Parts List

Item No.

Part No.

Description

Qty.

1

BCH102

Tongue Clevis

1

2

BCH107

Drive Shaft Support Weldment

1

3

BCH100

Main Frame Weldment

1

4

MC109

Flange Bearing, 1 3/8”

2

5

MC138

Bearing Spacer *See note below

1

6

MC108L

Spline Shaft

1

7

BCH111

Driveline Shield

2

8

BCH112

Top Link

1

9

K-202

Top Link Pin

1

10

K-232

Hairpin

1

11

0-51

Tongue Jack

1

12

K-211

Hydraulic Cylinder, 3” x 8”

1

13

MC133

Cylinder Pin

2

14

MC134

Clip Pin

2

15

BCH114

Hydraulic Hose, ½” MP x 3/8” JIC, 122”

1

16

BCH115

Hydraulic Hose, ½”MP x 3/8” JIC, 114”

1

17

BCH123

Hydraulic Hose, ½” MP x ½” MP, 122”

1

18

MC122

Elbow, 3/8” JIC M x ½” MP

2

19

OE-302

Pipe Coupler, ½” Female

1

20

0-57

Flow Restrictor, ½” NPT, 1/32”

1

21

MC124

Grease Seal

1

22

MC125

Inner Bearing

2

23

MC126

Wheel Hub

2

24

MC127

Outer Bearing

2

25

MC128

Flatwasher

2

26

MC129

Castle Nut

2

27

MC130

Cotter Pin

2

28

MC131

Hub Cap

2

29

MC135

Lug Bolt

12

30

MC103

Tire & Wheel Assembly

2

31

0-157

Hex Capscrew, 3/8” x 1 ½” GR5

2

32

MCH38F

Flatwasher, 3/8”

4

33

NL38

Nylock Nut, 3/8”

2

34

0-172

Hex Capscrew, ½” x 1 ½” GR5

6

35

H12-412

Hex Capscrew, ½” x 4 1/2” GR5

4

36

0-173

Lockwasher, ½”

10

37

0-153

Hex Nut, ½”

10

38

BCH587

Hex Capscrew, 5/8” x 7” GR5

2

39

MCH580

Nylock Nut, 5/8”

2

40

BCH3465

Hex Capscrew, ¾” x 6 ½” GR8

1

41

0-170

Hex Nut, ¾”

1

42

K-324

Lockwasher, ¾”

1

Not shown MC110

Drive Shaft

1

*After serial #8004 Bearing Spacer was welded to Drive Shaft Support Weldment

Summary of Contents for BCH610

Page 2: ......

Page 13: ...11 Notes ...

Page 14: ...12 ...

Page 16: ...14 Notes ...

Page 18: ......

Page 19: ......