6

Attach the Top Link using Pin and Hairpin.

Attach the Tongue Clevis using two 5/8” x 6” Capscrews and Nylock Nuts.

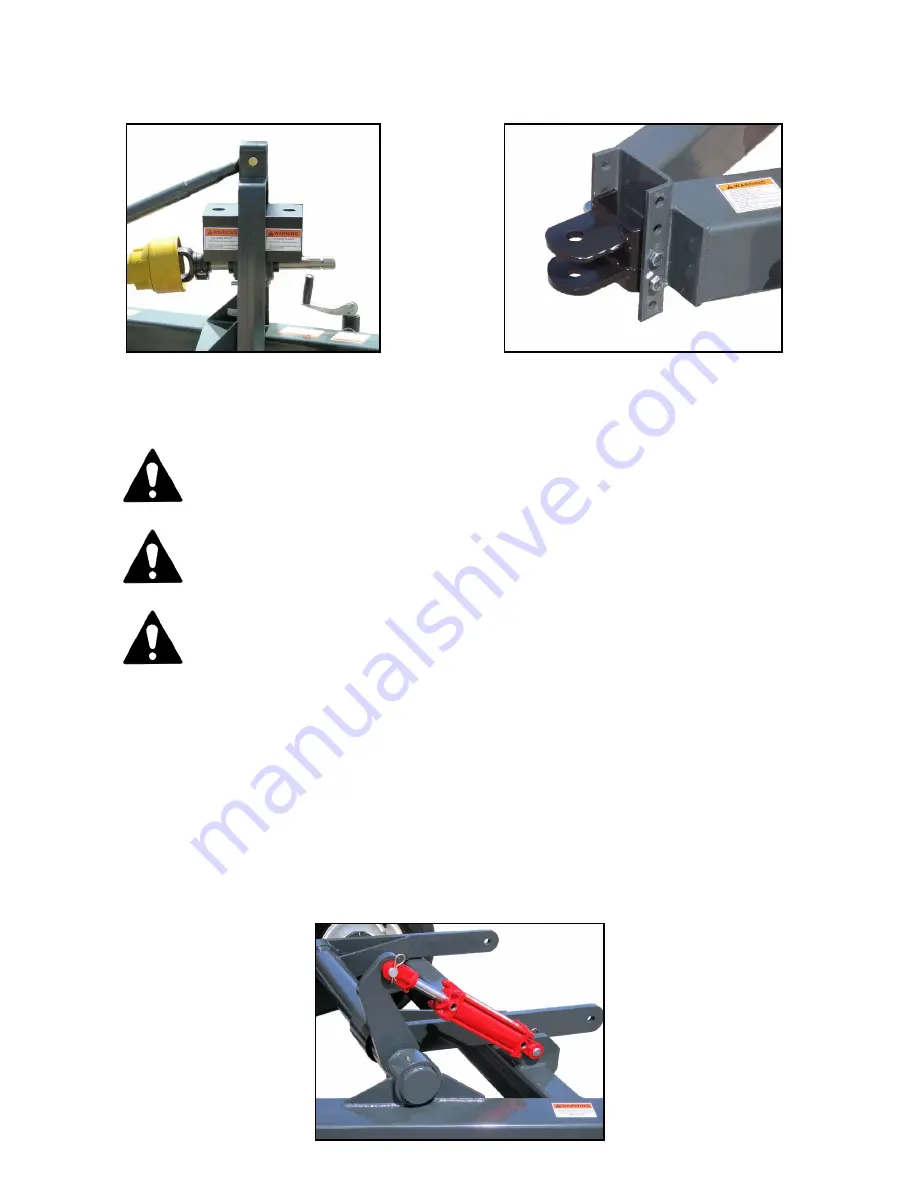

WARNING:

Always wear protective eye goggles and use a magnifying

Glass or hold a piece of wood on suspected leaks. Pinhole hydraulic leaks

can penetrate skin. Do not touch.

CAUTION:

Make sure a restrictor is installed in one of the hydraulic lines.

Failure to use a restrictor will allow the machine to raise and lower rapidly

and could result in damage to the machine and injury to bystanders.

CAUTION: Operate the cylinder through the cycle a few times to

expel air from the system. Failure to fully charge the hydraulic system

could result in injury when the mower falls abruptly.

Mount the Hydraulic Cylinder on the Carrier and install two ½” NPT Male x 3/8” JIC Male

Elbows in the Hydraulic Cylinder.

Note:

Do not use Teflon tape, only use liquid type thread

sealant. Attach the 114” Hose with ½” NPT Male - 3/8” JIC Swivel ends to the front port of the

Hydraulic Cylinder. Attach the 122” Hose with ½” NPT Male – 3/8” JIC Swivel ends to the rear

port of the Hydraulic Cylinder. Install the Restrictor on one of the Hydraulic Hoses before

installing a Hydraulic Coupler. Route the Hydraulic Hoses through the loop on the side of Drive

Shaft Support Weldment and then to the tractor. Before attaching a Mower to the Mower Carrier

operate the Hydraulic Cylinder several times to purge the air out of the system to prevent any

sudden drop.

A

A

T

T

T

T

A

A

C

C

H

H

I

I

N

N

G

G

M

M

O

O

W

W

E

E

R

R

Summary of Contents for BCH610

Page 2: ......

Page 13: ...11 Notes ...

Page 14: ...12 ...

Page 16: ...14 Notes ...

Page 18: ......

Page 19: ......